Integration Guide | PUBLIC

Document Version: 2408–2024-08-24

SAP Digital Manufacturing Integration Guide

© 2024 SAP SE or an SAP aliate company. All rights reserved.

THE BEST RUN

Content

1 Introduction................................................................4

2 SAP Digital Manufacturing for execution Integration.................................7

2.1 Integration with SAP S/4HANA or SAP ERP.......................................... 9

Minimum Version Requirements and Supported Scenarios.............................9

Overview Integration with SAP S/4HANA / SAP ERP for Discrete Industries.................12

Overview Integration with SAP S/4HANA / SAP ERP for Process Industries.................13

Technical Integration with SAP S/4HANA or SAP ERP ................................15

Business Integration with SAP S/4HANA or SAP ERP............................... 128

Customizing the Integration Scenario...........................................312

Upgrade Information...................................................... 318

2.2 Integration with SAP S/4HANA Cloud.............................................319

Minimum Version Requirements and Supported Scenarios...........................320

Overview Integration with SAP S/4HANA Cloud for Discrete Industries...................321

Overview Integration with SAP S/4HANA Cloud for Process Industries...................322

Technical Integration with SAP S/4HANA Cloud ...................................323

Business Integration with SAP S/4HANA Cloud................................... 350

2.3 Integration with EWM........................................................409

Minimum Version Requirements and Supported Scenarios........................... 410

Connecting to EWM in SAP S/4HANA 1909 to 2020 (Deprecated).................... 410

Connecting to EWM in SAP S/4HANA 2021.......................................416

Mapping Plants (Plant Conversion)............................................436

2.4 Troubleshooting Overview.....................................................438

Troubleshooting for the Integration with SAP S/4HANA ............................. 439

2.5 Extensibility Information......................................................446

3 Shop Floor Integration......................................................447

3.1 Integration Scenarios........................................................ 447

Digital Twin Conguration...................................................448

Machine Data Integration...................................................448

Production Process Conguration.............................................450

Production Process Execution................................................450

3.2 Integrate with the Production Connector for SAP Digital Manufacturing.....................450

Enable Communication from the Production Connector to the Cloud....................452

Minimum Version Requirements and Supported Scenarios........................... 453

Assignment of Production Connector Role to IAS User Groups.........................453

3.3 Integration with SAP MII......................................................454

2

PUBLIC

SAP Digital Manufacturing Integration Guide

Content

3.4 Troubleshooting - Congure Production Connectivity App...............................458

Connectivity Issues.......................................................458

Internal Server Error...................................................... 459

User Authorization Issues...................................................459

4 Resource Orchestration Integration............................................460

4.1 Overview Characteristics-Based Sequencing........................................460

Integration with SAP S/4HANA...............................................461

4.2 Integration with SAP Manufacturing Execution...................................... 464

Minimum Version Requirements and Supported Scenarios...........................465

Integrating SAP Manufacturing Execution On-Premise to Resource Orchestration (Inbound)

.....................................................................466

Integrating Resource Orchestration to SAP Manufacturing Execution On-Premise (Outbound)

..................................................................... 472

Conguring Master Data for Resource Orchestration in SAP ME System..................478

Maintain Custom Data.....................................................480

4.3 Integration with SAP SuccessFactors Employee Central................................482

Before You Start......................................................... 483

Create a Master Data Integration Instance.......................................484

Create Distribution Models for Cost Center and Workforce Person......................486

Create a Destination for Cost Center and Workforce Person...........................488

Create a Destination for Availability............................................490

Congure SAP Digital Manufacturing for resource orchestration to Retrieve Data............494

Congure SAP Digital Manufacturing for resource orchestration to Use Master Data......... 495

4.4 Data Engineering Conguration.................................................495

Manage Data Agents......................................................496

Manage Connections......................................................497

Manage Data Replicas.....................................................498

5 SAP Digital Manufacturing for edge computing Integration..........................500

5.1 Enable Production Connector to Invoke Edge Services.................................500

5.2 SAP MQTT Broker...........................................................501

SAP Digital Manufacturing Integration Guide

Content

PUBLIC 3

1 Introduction

This Integration Guide provides you with information on the available integration options and gives you step-by-

step instructions to integrate your business system with SAP Digital Manufacturing.

Overview

SAP Digital Manufacturing is a fully cloud-based manufacturing execution system that focuses on the

execution, data analysis, control, and integration of manufacturing processes. SAP Digital Manufacturing

connects the shop oor with your business system to optimize resources and execution.

This Integration Guide gives you an overview of the existing integration scenarios and provides you with

detailed information on the steps required to integrate your business system with SAP Digital Manufacturing.

The guide covers the technical as well as the business aspects of your integration project. You’ll learn how to

enable the data exchange between systems and how to make sure that the right business data are transferred.

Example of a Hybrid Digital Manufacturing Landscape

SAP Digital Manufacturing can be integrated with the following business systems:

• SAP ERP

4

PUBLIC

SAP Digital Manufacturing Integration Guide

Introduction

• SAP S/4HANA

• SAP S/4HANA Cloud

• SAP Manufacturing Integration and Intelligence

• Production Connector for SAP Digital Manufacturing

• SAP Overall Equipment Eectiveness Management

• SAP Extended Warehouse Management

This integration enables the exchange of transaction data, master data, and machine data between the

customer-level business systems and SAP Digital Manufacturing for execution or SAP Digital Manufacturing for

insights.

Integration Options

The following integration scenarios are available:

• SAP Digital Manufacturing for execution Integration [page 7]

• Shop Floor Integration [page 447]

• Resource Orchestration Integration [page 460]

As an extensive capability of SAP Digital Manufacturing, SAP Digital Manufacturing for edge computing

also provides multiple integration scenarios. For more information, see SAP Digital Manufacturing for edge

computing Integration [page 500].

Recommendation

The business scenarios presented in this Integration Guide are examples of how you might use SAP

software in your company. The business scenarios are intended only as models and may not run in your

specic system landscape exactly as they’re described here. Be sure to check your requirements and

systems to determine whether these scenarios can be used productively at your site. Also, we recommend

that you test these scenarios thoroughly in your test systems to ensure they’re complete and free of errors

before going live.

This Integration Guide primarily discusses the overall technical implementation of SAP Digital

Manufacturing and not its subcomponents. This means that additional software dependencies might exist

that aren’t mentioned explicitly in this document.

Minimum Version Requirements and Supported Scenarios

Here you'll nd detailed information on the minimum version requirements and supported scenarios:

• Minimum Version Requirements and Supported Scenarios for Integration with SAP ERP / SAP S/4HANA

[page 9]

• Minimum Version Requirements and Supported Scenarios for Integration with SAP S/4HANA Cloud [page

320]

• Minimum Version Requirements and Supported Scenarios for Integration with the Production Connector

[page 453]

SAP Digital Manufacturing Integration Guide

Introduction

PUBLIC 5

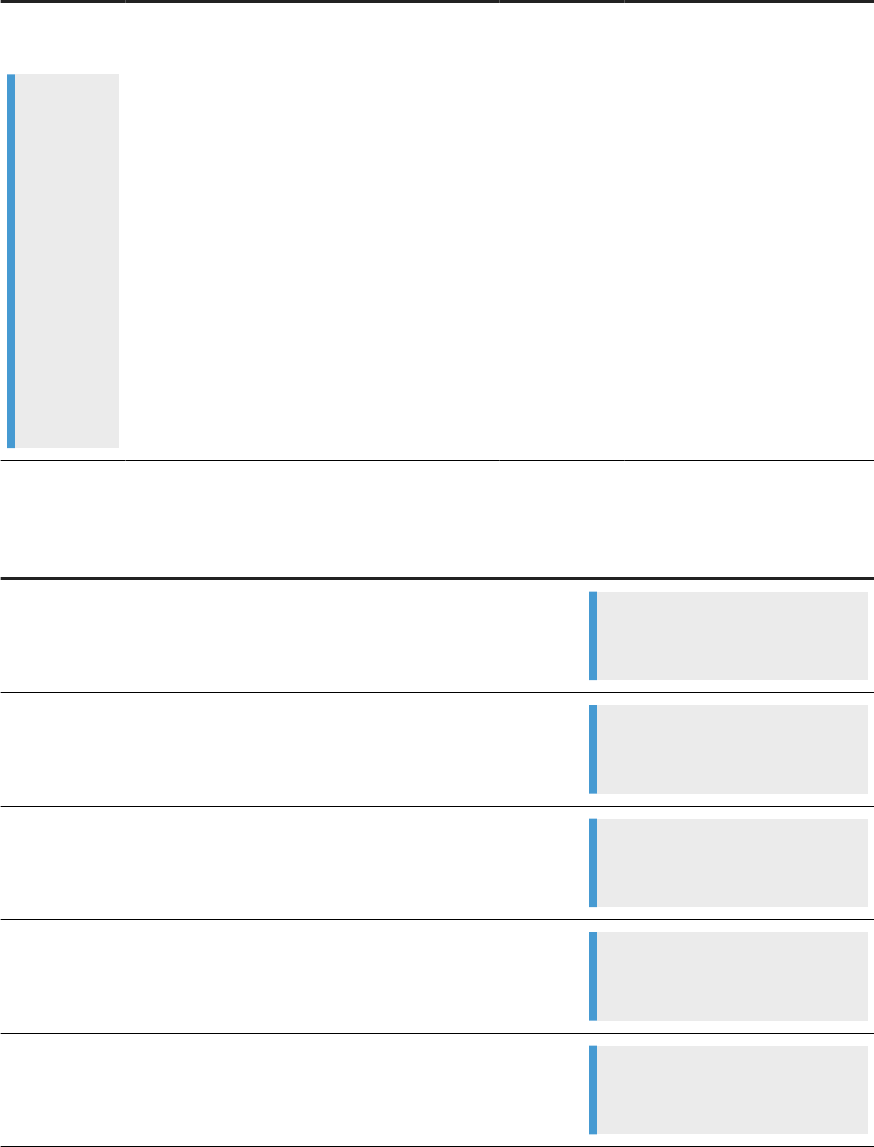

2 SAP Digital Manufacturing for execution

Integration

SAP Digital Manufacturing for execution supports various integration scenarios for both discrete and process

industries. The supported ERP systems include on-premise and cloud systems.

Overview

The following diagram gives you an overview of the possible integration scenarios between SAP Digital

Manufacturing for execution and its partner systems. It doesn't provide information on the relationships the

dierent partner systems might have with each other.

• Integration with SAP S/4HANA or SAP ERP [page 9]

• Integration with SAP S/4HANA Cloud [page 319]

• Integration with EWM [page 409]

• Integrate with the Production Connector for SAP Digital Manufacturing [page 450]

• Resource Orchestration Integration [page 460]

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 7

Business Scenarios

You can integrate SAP Digital Manufacturing for execution with SAP ERP, SAP S/4HANA, and SAP S/4HANA

Cloud to implement business scenarios for process and discrete industries. For more information, see:

• Overview Integration with SAP S/4HANA / SAP ERP for Discrete Industries [page 12]

• Overview Integration with SAP S/4HANA / SAP ERP for Process Industries [page 13]

• Overview Integration with SAP S/4HANA Cloud for Discrete Industries [page 321]

• Overview Integration with SAP S/4HANA Cloud for Process Industries [page 322]

Integration Scenarios

You can integrate SAP Digital Manufacturing for execution with various systems. The following table provides

an overview of the integration scenarios and their constituent components:

Integration Scenario

Integrated Sys-

tems

Integration with

SAP ERP

Integration with

SAP S/4HANA

Integration with

SAP S/4HANA

Cloud

Integration

with SAP

Manufacturing

Execution

1

Integration with

SAP Extended

Warehouse

Management

2

SAP ERP * *

SAP S/4HANA * *

SAP S/4HANA

Cloud

* *

SAP

Manufacturing

Execution

*

SAP Extended

Warehouse Man-

agement

* * * *

Cloud Connector * * * *

SAP Cloud

Integration

* * * *

•

1

Integration with SAP Manufacturing Execution is limited to Resource Orchestration.

•

2

Integration with SAP Extended Warehouse Management is limited to on-premise systems that are either

standalone or embedded with SAP S/4HANA.

Related Information

Integration with SAP S/4HANA or SAP ERP [page 9]

Integration with SAP S/4HANA Cloud [page 319]

8

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Integration with SAP Manufacturing Execution [page 464]

Integration with EWM [page 409]

2.1 Integration with SAP S/4HANA or SAP ERP

SAP Digital Manufacturing for execution uses SAP Cloud Integration to communicate with integrated SAP

S/4HANA or SAP ERP systems. You can connect multiple ERP systems, for example one system per plant or

country. The global SAP Digital Manufacturing for execution system is used across all plants.

After you've completed the onboarding procedures as described in Onboarding and User Management, you

can continue with the congurations required to establish connectivity between SAP Digital Manufacturing and

SAP S/4HANA or SAP ERP systems.

Integration with SAP S/4HANA or SAP ERP enables the data transfer from and to these systems. The data

transfer can be broadly categorized into master data and transactional data. To transfer data, you need to

make sure all prerequisites are met and the required congurations are set up. For more information, see

Technical Integration with SAP S/4HANA or SAP ERP [page 15] and Business Integration with SAP S/4HANA

or SAP ERP [page 128].

Related Information

Minimum Version Requirements and Supported Scenarios [page 9]

2.1.1Minimum Version Requirements and Supported

Scenarios

This topic describes the minimum release requirements, supported scenarios, and limitations for integrating

SAP Digital Manufacturing with SAP ERP and SAP S/4HANA.

Minimum Release Requirements

To use all features provided by SAP Digital Manufacturing, you require:

• SAP ERP 6.0 EHP7 or higher

• SAP S/4HANA 1709 onwards

Note

For some integration message types, there are higher versions requested. For more information on the

supported message types and versions, see 3050090

.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 9

Supported Scenarios

Scenario SAP ERP SAP S/4HANA

Production order

Yes Yes

Process order

Yes Yes

Planned order Yes Yes

Material

Yes Yes

Characteristic Yes Yes

Class Yes Yes

Classication Assignment Yes Yes

Bill of materials

Yes Yes

Routing

Yes Yes

Recipe

Yes Yes

Work center

Yes Yes

Equipment PRT

Yes Yes

Work instruction at order header level

Yes Yes

Yield/scrap

Yes Yes

Inventory

Yes Yes

Return inventory

Yes Yes

Scrap inventory

Yes Yes

Use Resource Orchestration for

scheduling

Yes

Yes

Middleware Requirements

• SAP Cloud Integration and Cloud Connector are required as middleware

• SAP Cloud Integration in the Neo environment is supported

10

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Supported IDocs

IDoc SAP ERP SAP S/4HANA

MATMAS03

Yes Yes

MATMAS04

Yes Yes

MATMAS05

Yes Yes

CHRMAS05

Yes Yes

CLSMAS04

Yes Yes

CLFMAS02

Yes Yes

BOMMAT04

Yes No

BOMMAT05

No Yes

LOIROU04

Yes Yes

LOIPRO05 (production and process

orders)

Yes

Yes

LOIPLO02 (planned order) Yes Yes

INVCON02

Yes No

INVCON03

Yes Yes

LOIWCS03

Yes Yes

EQUIPMENT_CREATE02

Yes Yes

PP_SHIFT01

Yes Yes

Note

To nd out more about any limitations or restrictions that could apply to your scenario, see 3379404 .

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 11

2.1.2Overview Integration with SAP S/4HANA / SAP ERP for

Discrete Industries

The following diagram provides an overview of the integration of SAP Digital Manufacturing for execution and

SAP ERP or SAP S/4HANA for discrete industries. Select highlighted areas for more detailed information.

• Work Center Integration [page 162]

• Bill of Material Integration [page 149]

• Routing Integration [page 165]

• Production Version [page 152]

• Transferring QM Defect Code Groups and Codes from SAP S/4HANA [page 164]

• Tool Integration [page 168]

• Production Order Integration [page 171]

• Transfer of Floor Stock Data [page 224]

• Material Integration [page 130]

• Production Order Status Conrmation [page 186]

• Inspection Results Recording (Process Order and Production Order) [page 223]

• Congure Inspection Points

• Transfer of Floor Stock Return and Scrap Data [page 231]

• Integration with EWM [page 409]

• Staging Request Upon Order Release

• Material Consumption (Order POD)

• EWM Goods Receipt (Work Center POD)

12

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

• EWM Goods Receipt (Order POD)

• Component Removal

• Transferring a Planned Order [page 205]

• Planned Order Integration [page 204]

• Activity Conrmation [page 195]

• Quantity Conrmation [page 196]

• Classication Integration [page 138]

• Conguring a Production Order with a BOM and Routing (Make-to-Stock or Make-to-Order Manufacturing)

[page 174]

• Conguring a Production Order with Serial Numbers [page 176]

• Conguring a Production Order with a Batch Number [page 178]

• Conguring a Production Order with Document Info Records [page 180]

• Conguring a Production Order with Scheduling Information [page 182]

• Transfer of Production Order with Operation-Level Scheduling [page 183]

• Transferring a Production Order with PRT Assignment [page 185]

• Production Order Complete [page 192]

2.1.3Overview Integration with SAP S/4HANA / SAP ERP for

Process Industries

The following diagram provides an overview of the integration of SAP Digital Manufacturing for execution and

SAP ERP or SAP S/4HANA for process industries. Select highlighted areas for more detailed information.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 13

• Material Integration [page 130]

• Work Center Integration [page 162]

• Bill of Material Integration [page 149]

• Recipe Integration [page 168]

• Production Version [page 152]

• Transferring QM Defect Code Groups and Codes from SAP S/4HANA [page 164]

• Tool Integration [page 168]

• Process Order Integration [page 197]

• Transferring a Process Order with Inspection Lot (type 03) [page 198]

• Transfer of Floor Stock Data [page 224]

• Process Order Status Conrmation [page 200]

• Activity Conrmation [page 203]

• Batch Characteristics Update [page 221]

• Congure Inspection Points

• Transfer of Floor Stock Return and Scrap Data [page 231]

• Staging Request Upon Order Release

• Material Consumption (Order POD)

• Inspection Results Recording (Process Order and Production Order) [page 223]

• Integration with EWM [page 409]

• EWM Goods Receipt (Work Center POD)

• EWM Goods Receipt Cancellation

• Cancelling Goods Issues

14

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

• Classication Integration [page 138]

• Quantity Conrmation [page 202]

2.1.4Technical Integration with SAP S/4HANA or SAP ERP

Here are the administrative congurations that need to be set up to enable communication between SAP

Digital Manufacturing for execution and SAP S/4HANA or SAP ERP.

Integration Overview

As the On-Premise Enterprise Network environment is protected by a rewall, an asymmetrical communication

design connects SAP Digital Manufacturing for execution to SAP S/4HANA or SAP ERP.

• Build HTTP Connection [page 30]

• Data Replication Framework [page 36]

• Connect SAP Cloud Integration to SAP Digital Manufacturing [page 66]

• Connect SAP Digital Manufacturing to SAP Cloud Integration [page 87]

• Setting Up the Cloud Connector [page 22]

• Set Up Connection Between SAP Cloud Integration, Cloud Connector, and SAP S/4HANA or SAP ERP

[page 106]

• Congure SAP Digital Manufacturing for Outbound Integration [page 108]

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 15

From SAP S/4HANA or SAP ERP to SAP Digital Manufacturing for execution, HTTPS is used to connect SAP

Cloud Integration (previously called CPI). SAP Cloud Integration parses and sends the transaction to SAP

Digital Manufacturing for execution for processing. Transaction examples: material import and production

import.

From SAP Digital Manufacturing for execution to SAP S/4HANA or SAP ERP, an RFC is used to call SAP S/

4HANA or SAP ERP BAPI from the SAP Cloud Connector. Transaction examples: production yield conrmation

and production scrap conrmation.

In certain scenarios, you can also use OData for direct outbound calls to SAP S/4HANA to connect the

systems. This doesn't apply for SAP ERP. For more information, see Enable Direct Communication To SAP

S/4HANA [page 109].

Note

For more information on the supported message types and needed integration artifacts, see

0003050090

.

Note

Plant names need to be unique across the dierent ERP systems at the client level.

Note

You can check your integration scenario using the Check Integration Conguration functionality provided by

the Integration Message Dashboard app.

After choosing Check Integration Conguration, you select an integration message to start an automated

test of the integration conguration that covers the full integration scenario from SAP Digital

Manufacturing to the connected ERP system and back. The following tests are performed:

• Destination check

• SAP Cloud Integration parameter check

• SAP Cloud Integration artifact check

• Inbound connectivity check

In case of an error, a message will point you to the solution.

Tip

If you're an integration developer and want to learn more about how to design integration ows, you

can refer to the Integration Flow Design Guidelines. You'll nd there lots of information on the underlying

concepts as well as practical examples that will help you deepen your knowledge. For more information, see

Integration Flow Design Guidelines.

If you're particularly interested in optimizing workow performance, you can jump right to this topic:

Optimize Performance.

16

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Overview Integration Steps

For the technical integration of SAP Digital Manufacturing for execution with SAP S/4HANA or SAP ERP,

perform the tasks described in the following topics:

1. Before You Start [page 17]

2. Setting Up the Cloud Connector [page 22]

3. Build HTTP Connection [page 30]

4. Data Replication Framework [page 36]

5. Prepare Credentials for Initial Parameter Deployment [page 52]

6. Connect SAP Cloud Integration to SAP Digital Manufacturing [page 66]

7. Connect SAP Digital Manufacturing to SAP Cloud Integration [page 87]

8. Set Up Connection Between SAP Cloud Integration, Cloud Connector, and SAP S/4HANA or SAP ERP

[page 106]

9. Congure SAP Digital Manufacturing for Outbound Integration [page 108]

10. Enable Direct Communication To SAP S/4HANA [page 109]

Related Information

Asynchronous Communication with SAP Cloud Integration [page 112]

Troubleshooting Overview [page 438]

2.1.4.1 Before You Start

This page shows you the prerequisite steps that must be completed before conguring integration with SAP

S/4HANA or SAP ERP.

Before you start, you must have performed the following steps:

• If you integrate SAP Digital Manufacturing with multiple SAP S/4HANA or SAP ERP, these systems need to

have unique system IDs. Systems are identied at the client level.

• Complete the onboarding process

Note

This includes the conguration of the S4H_INTEGRATION_OAUTH destination. The destination data

is used by SAP Digital Manufacturing to provide authentication and authorization for internal system

communication. You also require it to integrate with SAP ERP, SAP S/4HANA, and SAP S/4HANA

Cloud.

• Download SAP Cloud Integration package. For more information on SAP Cloud Integration, see SAP Cloud

Integration.

Tip

The change log of the SAP S/4HANA Integration with SAP Digital Manufacturing package is available

here: 3315636 .

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 17

Tip

It's recommended to deploy all iFlows contained in the SAP S/4HANA Integration with SAP Digital

Manufacturing package. For more information on the required artifacts for all integration message

types, see 3050090 .

• Create a separate subaccount for your SAP Cloud Integration tenant in SAP BTP cockpit in addition to

your SAP Digital Manufacturing subaccount. Without two separate subaccounts, the direct communication

scenarios that you might want to use now or in the future aren't supported. For more information, see

Enable Direct Communication To SAP S/4HANA [page 109].

• Upload SSL certicates [page 18]

• Create a Technical User for SAP S/4HANA [page 20]

• Know how to get the SAP Cloud Integration Management URL [page 21]

• Know how to get the SAP Cloud Integration Runtime URL [page 22]

• The following business functions, which are the technical basis for the Data Replication Framework (DRF),

have been implemented in SAP S/4HANA or SAP ERP:

• LOG_PP_MES_INT_01

• LOG_PP_MES_INT_02

• LOG_PP_MES_INT_03

• You've implemented BADI CO_MES_INT_REDISTRIBUTION in SAP S/4HANA or SAP ERP. This BADI

makes sure that the integrated ERP system doesn't communciate an order change to SAP Digital

Manufacturing after receiving the release notication (RMES). For more information, see 2165261

.

Next Steps

• Setting Up the Cloud Connector [page 22]

• Build HTTP Connection [page 30]

• Set Up Data Replication Framework (DRF) [page 36]

• Connect SAP Cloud Integration to SAP Digital Manufacturing [page 66]

• Connect SAP Digital Manufacturing to SAP Cloud Integration [page 87]

• Set Up Connection Between SAP Cloud Integration, Cloud Connector, and SAP S/4HANA or SAP ERP

[page 106]

• Congure SAP Digital Manufacturing for Outbound Integration [page 108]

• Enable Direct Communication To SAP S/4HANA [page 109]

2.1.4.1.1 Upload SSL Certicates

This page shows you how to upload SSL certicates to build the trust between the systems.

The certicate uploading processes mentioned below apply to SAP Cloud Integration in both Neo and Cloud

Foundry environments.

18

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Upload SSL Certicate of SAP Cloud Integration to SAP ERP or SAP S/

4HANA

Download SAP Cloud Integration Certicate

1. Go to the SAP Cloud Integration management URL, which you can nd in the service key of your api plan

service instance in your SAP Cloud Integration subaccount in SAP BTP cockpit. You can ignore any 404

error when accessing the URL. For details, see How to Get SAP Cloud Integration Management URL [page

21].

2. Choose in the address bar to download the SSL certicate of SAP Cloud Integration. Save the certicate

in le format base-64 encoded X.509 (.cer).

Upload Certicate to SAP ERP or SAP S/4HANA

1. Log on to the SAP ERP or SAP S/4HANA system as an Administrator.

2. Use the transaction STRUST to access Trust Manager.

3. Upload the certicate you saved in previous steps to SSL client SSL Client (Standard) node.

Upload SSL Certicate of SAP Digital Manufacturing to SAP Cloud

Integration

Download SAP Digital Manufacturing Certicate

If your SAP Cloud Integration tenant is already using DigiCert Global Root G2, you don't need to follow

the steps belows because SAP Digital Manufacturing also utilizes DigiCert Global Root G2 certication.

1. Log on to SAP BTP cockpit and go to your SAP Digital Manufacturing subaccount.

2. Under

Instances and Subsriptions Subscriptions , choose your SAP Digital Manufacturing application

in the Application column.

3. Choose in the address bar to download the certicate. Save the certicate in le format base-64

encoded X.509 (.cer).

Upload Certicate to SAP Cloud Integration

For more information, see Importing a Certicate.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 19

2.1.4.1.2 Create a Technical User for SAP S/4HANA

To connect SAP S/4HANA with SAP Cloud Integration and Cloud Connector, you need to create a technical

user.

Prerequisites

• Access to transaction SU01

• Authorization to create technical users in the system

Context

You need a technical user for SAP S/4HANA to set up a connection between SAP S/4HANA, SAP Cloud

Integration, and Cloud Connector.

Procedure

1. Log on to SAP S/4HANA.

2. Open transaction SU01.

3. Enter the name for the technical user and choose Technical User to create the user.

4. As User Type, choose System from the dropdown menu.

5. Assign a password for the user.

6. In the Documentation tab, enter a description for the user.

7. In the Proles tab, assign SAP_ALL or SAP_NEW to your user.

8. Choose Save.

Results

You have created a technical user for SAP S/4HANA.

20

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

2.1.4.1.3 How to Get SAP Cloud Integration Management

URL

This page shows how to get the management URL of SAP Cloud Integration.

Prerequisites

You need to be a member of the global account in order to access the instances and subscriptions of SAP

Cloud Integration tenant and get the management URL.

Get SAP Cloud Integration Management URL (Cloud Foundry Environment)

1. In SAP BTP cockpit, select your SAP Cloud Integration subaccount and then choose Instances and

Subscriptions.

2. In the Instances tab, choose an instance with api as Plan.

3. In the Service Keys tab, choose the service key.

4. In the Credentials window, you nd the SAP Cloud Integration management URL in the url eld.

Example

https://<Cloud Integration tenant>.it-

<...>.cfapps.<datacenter>sap.hana.ondemand.com

Note

This instance is created during the integration process. For more information, see Create a Service

Instance and Key with client credential authorization [page 62].

Get SAP Cloud Integration Management URL (Neo Environment)

1. In SAP BTP cockpit, select your subaccount and then choose Applications Subscriptions .

2. In the Subscribed Java Applications section, choose the <Cloud Integration tenant>tmn application.

3. In the Application URLs section, you see the management URL named https://<Cloud Integration tenant>-

tmn.<…>.eu1.hana.ondemand.com.

Related Information

How to Get SAP Cloud Integration Runtime URL [page 22]

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 21

2.1.4.1.4 How to Get SAP Cloud Integration Runtime URL

This page shows how to get the runtime URL of SAP Cloud Integration.

Prerequisites

You need to be a member of the global account in order to access the instances and subscriptions of Cloud

Integration tenant and get the runtime URL.

Get SAP Cloud Integration Runtime URL (Cloud Foundry Environment)

1. In SAP BTP cockpit, select your SAP Cloud Integration subaccount and then choose Instances and

Subscriptions.

2. In the Instances tab, nd the instance for the Process Integration Runtime service, which has integration-

ow as plan, and choose the link to the key in the Credentials column.

3. In the key credentials pop-up, under JSON, you can see the runtime URL under the url tag.

Note

This instance is created during the integration process. For more information, see Create Instances in SAP

Cloud Integration Subaccount [page 97].

Get SAP Cloud Integration Runtime URL (Neo Environment)

1. In SAP BTP cockpit, select your SAP Cloud Integration subaccount and then choose Applications

Subscriptions .

2. In the Subscribed Java Applications section, choose the <Cloud Integration tenant>imap application.

3. In the Application URLs section, you will see the runtime URL named https://<Cloud Integration tenant>-

imap.avtsbhf.eu1.hana.ondemand.com.

Related Information

How to Get SAP Cloud Integration Management URL [page 21]

2.1.4.2 Setting Up the Cloud Connector

Congure a Cloud Connector that acts as a reverse invoke proxy between an on-premise network and the SAP

Business Technology Platform. The Cloud Connector comes standard as part of the SAP Cloud Integration

22

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

service and serves as a link between the SAP Business Technology Platform and on-premise systems such as

SAP S/4HANA.

In SAP Digital Manufacturing, the following integration scenarios use a Cloud Connector:

• Scenario 1 - Execution2S4 [page 9]: SAP Digital Manufacturing (execution) → SAP Cloud Integration →

Cloud Connector → SAP S/4HANA

• Scenario 2 - REO2ME [page 464]: SAP Digital Manufacturing (resource orchestration) → SAP Cloud

Integration → Cloud Connector → SAP Manufacturing Execution

• Scenario 3 - PPD/Insights/MM2PCo [page 450]: SAP Digital Manufacturing (Production Process

Designer / insights / Production Connectivity Model) → Cloud Connector → Production Connector

2.1.4.2.1 Install Cloud Connector

Find out how to install the Cloud Connector.

Context

The installation les for the Cloud Connector are located at SAP Development Tools.

For prerequisites and instructions for installing the Cloud Connector, see the user assistance for SAP BTP

Connectivity.

After the installation, an Administrator user account is automatically created. The initial password is

manage. You're required to change the initial password when you log in for the rst time.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 23

2.1.4.2.2 Congure Subaccounts in Cloud Connector

For each SAP Business Technology Platform subaccount that you want to connect with an on-premises

system, congure a tenant / customer subaccount in the Cloud Connector.

Prerequisites

• You need a user account for the subaccount to establish the connection between the SAP Business

Technology Platform subaccount and the Cloud Connector. For Cloud Foundry and Neo environments, the

requirements vary for this user.

• For a subaccount in the Cloud Foundry environment, the subaccount user must be a security

administrator of the subaccount.

• For a subaccount in the Neo environment, the subaccount user must have the scope

manageSCCTunnels. You can assign the user to the predened role Cloud Connector Admin or

Administrator, or assign the user to a custom role that includes the scope.

• You have congured an HTTP proxy for the Cloud Connector to access the Internet. The proxy must

support SSL communication.

Note

With the Cloud Connector installed, you can congure the rst subaccount and proxy. To do this, on the

initial conguration page look for the proxy settings in

Connector Conguration .

Context

You always have two separate subaccounts: one for SAP Digital Manufacturing and one for SAP Cloud

Integration.

For the following scenarios, congure the Neo or Cloud Foundry subaccount for SAP Cloud Integration in the

Cloud Connector:

• Execution2S4

• REO2ME

For the following scenario, congure the Cloud Foundry subaccount for SAP Digital Manufacturing in the Cloud

Connector:

• PPD/insights/MM2PCo

For more information about these scenarios, see Setting Up the Cloud Connector [page 22].

24

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Procedure

1. 1. Using a web browser, log on to the Cloud Connector by using https://<hostname>:<port> as

Administrator.

Note

<hostname> is the hostname of the machine on which the Cloud Connector is installed. If you access

the Cloud Connector locally from the same machine, enter localhost. For <port>, enter the port

that you specied during the installation.

The initial password for Administrator is manage.

2. Choose Connector Add Subaccount .

3. In the Add Subaccount screen, enter the following information:

Field

Description

Region Select the data center in which the SAP Business Technology Platform subaccount

is hosted.

Subaccount

•

[Cloud Foundry]: Enter the subaccount ID.

•

[Neo]: Enter the technical name of the subaccount.

Note

You can nd the subaccount ID and technical name in the subaccount list in the

global account or on the overview page of each subaccount.

Subaccount User

•

[Cloud Foundry]: Enter the email address a subaccount user uses to log in to

the SAP Business Technology Platform cockpit.

•

[Neo]: Enter the P- or S- ID of a subaccount user.

Password Enter the password that the subaccount user uses to log in to the SAP Business

Technology Platform cockpit.

Location ID If you use more than one Cloud Connector to connect to the same subaccount,

dene a unique location ID per Cloud Connector for the subaccount.

4. Save the subaccount.

5. On the Subaccount Dashboard, in the Actions column, choose (Connect this subaccount) for this

subaccount.

Results

The status of the subaccount is displayed as Connected in the Cloud Connector.

You can also verify the connection status of the subaccount in the SAP Business Technology Platform cockpit.

In the subaccount, choose

Connectivity Cloud Connectors . The status should be Connected.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 25

Related Information

Congure trust to SAP Digital Manufacturing by dening an allowlist of cloud applications that can use the

Cloud Connector.

Initial Conguration

Cloud Foundry: Add Organization Members Using the Cockpit

Neo: Add Members to Your Subaccount

2.1.4.2.3 Congure Access Control

Expose an on-premise system to the cloud and specify the resources accessible from the cloud.

Context

To expose an on-premise system, create a virtual system in the Cloud Connector and then map it to an internal

on-premise system. When making the conguration, you need to dene a virtual host and a virtual port for the

virtual system. The virtual host and port are used to identify the on-premise system when creating destinations

in the corresponding SAP Business Technology Platform subaccount.

In addition, you must specify the resources that are accessible from the cloud. This step is required even if you

don’t limit access to resources. In other words, you need to explicitly specify that all resources are accessible.

For more information about the dierent integration scenarios, see Setting Up the Cloud Connector [page 22].

Procedure

1. In the Cloud Connector administration console, choose

<Subaccount> Cloud To On-Premise

ACCESS CONTROL .

2. In the Mapping Virtual To Internal System section, choose (Add).

A wizard appears that guides you through all the required settings.

3. In the wizard, enter the information according to the protocol used for communication and the specic

on-premise system.

• To communicate with SAP S/4HANA using RFC, follow the instructions at Congure Access Control

(RFC).

Applicable scenario: Execution2S4

• To communicate with SAP S/4HANA, SAP Manufacturing Execution, or the Production Connector

using HTTPS, follow the instructions at Congure Access Control (HTTP).

Applicable scenarios: REO2ME, PPD/Insights/MM2PCo

For the back-end type and principal type system, see the following table:

26

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

On-Premise System Back-end Type Principal Type

SAP S/4HANA ABAP System None

SAP Manufacturing Execution SAP Application Server

Java

None

Production Connector Other SAP System None

Note

The virtual host and virtual port can be freely dened. However, you can't edit the virtual host or virtual

port after you’ve added the mapping.

4. To specify resources that are accessible from the cloud, add the resources for the system.

You can nd detailed instructions at Congure Accessible Resources. In addition, for the required

congurations for each integration scenario, see the following table:

Scenario

Field Description

Execution2S4 Resource 1 Function Name Enter

CO_MES_PRODORDCONF_

CREATE_TT

Enabled Select the checkbox.

Naming Policy Select Exact Name.

Resource 2 Function Name Enter

CO_MES_SVK_WITH_LAN

GUAGE

Enabled Select the checkbox.

Naming Policy Select Exact Name.

Resource 3 Function Name Enter

MB_MES_GOODSMVT_CRE

ATE

Enabled Select the checkbox.

Naming Policy Select Exact Name.

Resource 4 Function Name Enter

QIRF_SEND_CATALOG_D

ATA2

Enabled Select the checkbox.

Naming Policy Select Exact Name.

Resource 5 Function Name Enter BAPI

Enabled Select the checkbox.

Naming Policy Select Prex.

PPD/Insights/MM2PCo URL Path Enter /cloudservices

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 27

Scenario Field Description

Enabled Select the checkbox.

Access Policy Select Path and all sub-

paths.

REO2ME URL Path Enter /

Enabled Select the checkbox.

Access Policy Select Path and all sub-

paths.

Note

For more information on the supported message types and available BAPIs, see 0003050090 .

The following BAPIs aren't used directly by SAP Digital Manufacturing but are used by SAP Cloud

Integration. Therefore, you must congure them in the cloud connector:

BAPI_TRANSACTION_COMMIT

BAPI_TRANSACTION_ROLLBACK

Results

In the SAP Business Technology Platform cockpit for the corresponding subaccount, you can nd

the accessible resource conguration. Choose Connectivity Cloud Connectors Exposed Back-End

Systems

.

2.1.4.2.4 Set Up Mutual Authentication with On-Premise

Systems

To set up mutual authentication between the Cloud Connector and an on-premise system, import an X.509

client certicate into the Cloud Connector.

Context

The certicate must be issued for the fully qualied domain name (FQDN) of the machine on which you've

installed the Cloud Connector. The Cloud Connector uses the so-called system certicate for all HTTPS

requests to back-end systems that request or require a client certicate.

28

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Related Information

Install a System Certicate for Mutual Authentication

2.1.4.2.5 Congure User Authentication Against On-

Premise Systems

To secure the communication with an on-premise system, apply dierent user authentication methods

depending on the integration scenario you use.

Context

For more information about the integration scenarios, see Setting Up the Cloud Connector [page 22].

Scenario

Authentication Method

Execution2S4

Basic authentication using destinations

For more information about how to create the destinations,

see Set Up Connection Between SAP Cloud Integration,

Cloud Connector, and SAP S/4HANA or SAP ERP [page

106].

REO2ME

Basic authentication using destinations

For more information about how to create the destinations,

see Integrating Resource Orchestration to SAP Manufactur-

ing Execution On-Premise (Outbound) [page 472].

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 29

Scenario Authentication Method

PPD/Insights/MM2PCo

Principal propagation using an X.509 CA certicate.

Note

Principal propagation is possible but not required from

15.4 SP2 onwards.

The certicate must be issued for the fully qualied domain

name (FQDN) of the machine on which you've installed the

Cloud Connector.

If you use a self-signed certicate, place the public key in the

Trusted store location in the le system of the Production

Connector server:

C:\ProgramData\SAP\ProdCon\CertificateSt

ores\CloudServicesHost\Trusted\certs

You can obtain the public key by choosing

Connector

Conguration ON PREMISE Download certicate in DER

format

.

For more information, see Congure a CA Certicate for

Principal Propagation.

Related Information

Authenticating Users Against On-Premise Systems

2.1.4.3 Build HTTP Connection

If you want to allow SAP S/4HANA or SAP ERP to access data from SAP Cloud Integration, you need an HTTP

connection for the communication.

Prerequisites

• You've got the SAP Cloud Integration runtime URL, which can be found in the provisioning email that is

sent when the space is created. For more information, see How to Get SAP Cloud Integration Runtime URL

[page 22].

• Depending on your environment and your preferred authentication method, you've got one of the following

users:

30

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Environment User Password Comment

Cloud Foundry P-User* authorized in SAP

Cloud Integration

P-User password Basic authentication

Cloud Foundry SAP Cloud Integration Cli-

ent ID

SAP Cloud Integration Cli-

ent Secret

Recommended authentica-

tion because no need to

change the password peri-

odically. Same security level

as with basic authentication

Neo

P-User* authorized in SAP

Cloud Integration

P-User password Basic authentication

Note

*For more information on how to obtain a P-user and on how grant it access to SAP Cloud Integration,

see Granting Your P-User Access to SAP Cloud Integration in Neo Environment [page 33] or Granting

Your P-User Access to SAP Cloud Integration in Cloud Foundry Environment [page 35].

To obtain a P-User ID, go to www.sap.com and register a new user using their email address.

If a user has already been registered with the SAP ID service (for example, at SAP Community or SAP

Developer Center) using the same email address, the user doesn't need to register again.

To nd an existing P-user, you've got two options:

• Log on to your account at www.account.sap.com using your email address. In your prole, under

Accounts, you nd your P-user ID.

• Log on to your account at www.sap.com using your email address. Go to your prole. Under

Personal Info Personal Data , you nd your P-user ID under User ID.

Caution

Your P-user and the corresponding email address must not be bound to SAP Universal ID. To check

whether or not your P-user and the corresponding email are already bound to SAP Universal ID, log on

to your account at www.sap.com and go to the Personal Info tab. Choose Access SAP Universal ID

account manager to access the Manage my Account app. Under Accounts, you nd your users.

If you get errors related to your credentials or the authorization, you can refer to 3085908 .

• If you want to use a P-user, it has been authorized for SAP Cloud Integration. For more information see,

Granting Your P-User Access to SAP Cloud Integration in Neo Environment [page 33] or Granting Your

P-User Access to SAP Cloud Integration in Cloud Foundry Environment [page 35].

Procedure

1. In SAP S/4HANA or SAP ERP, run transaction code SM59 to enter the Conguration of RFC Connections

screen.

2. Choose

Edit Create

3. Enter the following general data:

• Destination: Name of the HTTP connection, for example DME_INT

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 31

• Connection Type: G (HTTP Connection to External Server)

4. In the Technical Settings tab, enter data for the elds as follows:

Field Example Description

Target Host <Cloud Integration tenant>-i-

map.abcdef.eu1.hana.ondemand.com

(Neo) or <Cloud

Integration tenant>-abcd000-

rt.cfapps.sap.hana.ondemand.com

(Cloud Foundry)

SAP Cloud Integration runtime URL

that is sent by the provisioning email

when the space is created.

Alternatively, you can get the runtime

URL in the SAP BTP cockpit. For more

information, refer to How to Get SAP

Cloud Integration Runtime URL [page

22].

Note

Do not paste https:// as it is auto-

matically added.

Port 443

Path Prex /cxf/GenericMessageProcessor_00 The service implemented on SAP

Cloud Integration to receive the mes-

sage/IDOC from SAP S/4HANA or

SAP ERP.

Proxy Host Example

proxy.wdf.sap.corp

The proxy host for the external sys-

tem connection.

Proxy Service Example

8080

The proxy service for the external sys-

tem connection.

5. In the Logon & Security tab, activate SSL and complete the following settings for basic or OAuth 2.0

authentication:

Authentication Type

Credentials Certicate

Basic Authentication User and password DFAULT SSL Client (Standard)

Note

SSL needs to be set to Active.

32 PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Authentication Type Credentials Certicate

OAuth 2.0 Authentication Client ID and client secret

Note

Enter client ID and client secret

under Basic Authentication as

user and password.

DFAULT SSL Client (Standard)

Note

SSL needs to be set to Active.

6. Choose Connection Test to test the connection between SAP S/4HANA or SAP ERP and SAP Cloud

Integration.

Note

If the General Message Processor iFlow has been deployed in SAP Cloud Integration, the Status

HTTP Response shows the value 500, which, contrary to what is normally expected, indicates a

successful connection. Otherwise, an error message is displayed.

2.1.4.3.1 Granting Your P-User Access to SAP Cloud

Integration in Neo Environment

Learn how to authorize your P-user for SAP Cloud Integration in Neo environment to enable basic

authentication.

Prerequisites

• You've got the Administrator role for the subaccount.

• You've got the user IDs of the members that you want to add.

• You've got a P-user and password.

To obtain a P-User ID, go to www.sap.com

and register a new user using their email address.

If a user has already been registered with the SAP ID service (for example, at SAP Community or SAP

Developer Center) using the same email address, the user doesn't need to register again.

To nd an existing P-user, you've got two options:

• Log on to your account at www.account.sap.com using your email address. In your prole, under

Accounts, you nd your P-user ID.

• Log on to your account at www.sap.com

using your email address. Go to Manage my Account

Accounts to nd your users.

Caution

Your P-user and the corresponding email address must not be bound to SAP Universal ID. To check

whether or not your P-user and the corresponding email are already bound to SAP Universal ID, log on

to your account at www.sap.com and go to Manage my Account Accounts to nd your users.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 33

If you get errors related to your credentials or the authorization, you can refer to 3085908 .

Context

To enable basic authentication, you need to grant your P-user access to SAP Cloud Integration rst.

Procedure

1. In SAP BTP cockpit, select your SAP Cloud Integration subaccount.

2. Under Overview, choose Members.

3. Choose Add Members.

4. In the User IDs eld, enter your P-User ID.

5. Assign the following roles to the member: Administrator (predened role) and Developer (predened role).

6. Choose Add Members.

7. Choose Security Authorizations .

8. On the Users tab, enter your P-user ID and choose Show Assignments.

9. Choose Assign in the area for individual assignment, not group assignment.

The Assign Roles to User popup opens.

10. Go through the available subaccounts and applications to assign the following roles and save them:

ESBMessaging.send

AuthGroup.BusinessExpert

AuthGroup.Administrator

AuthGroup.IntegrationDeveloper

Results

Your P-user has now access to SAP Cloud Integration.

34

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

2.1.4.3.2 Granting Your P-User Access to SAP Cloud

Integration in Cloud Foundry Environment

Learn how to authorize your P-user for SAP Cloud Integration in Cloud Foundry environment to enable basic

authentication.

Prerequisites

• You've got the Administrator role for the subaccount in SAP BTP cockpit.

• You've got the user IDs of the members that you want to add.

• You've got a P-user and password.

To obtain a P-User ID, go to www.sap.com

and register a new user using their email address.

If a user has already been registered with the SAP ID service (for example, at SAP Community or SAP

Developer Center) using the same email address, the user doesn't need to register again.

To nd an existing P-user, you've got two options:

•

Log on to your account at www.account.sap.com

using your email address. In your prole, under

Accounts, you nd your P-user ID.

• Log on to your account at www.sap.com

using your email address. Go to Manage my Account

Accounts to nd your users.

Caution

Your P-user and the corresponding email address must not be bound to SAP Universal ID. To check

whether or not your P-user and the corresponding email are already bound to SAP Universal ID, log on

to your account at www.sap.com and go to Manage my Account Accounts to nd your users.

If you get errors related to your credentials or the authorization, you can refer to 3085908 .

Context

To enable basic authentication, you need to grant your P-user access to SAP Cloud Integration rst.

Procedure

1. In SAP BTP cockpit, select your SAP Cloud Integration subaccount.

2. Under Security Users , choose Create.

3. Under User Name, enter the e-mail address belonging to your P-user.

4. Choose Default Identity Provider.

5. Choose Create.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 35

6. Choose Security Role Collections .

7. Choose .

8. Give your collection a name, for example My_RoleCollection, and choose Create.

9. Select your collection and choose Edit.

10. On the Roles tab, under Role Name, choose and add the following roles to your collection:

MessagingSend

MessagePayloadsRead

AuthGroup_BusinessExpert

If you want to use the CPI Async Mode, there a some additional roles required. For more information, see

Asynchronous Communication with SAP Cloud Integration [page 112].

11. Under

Security Users , choose your user.

12. In the detail view, choose Assign Role Collection to make the following assignments:

My_RoleCollection

PI_Integration_Developer (predened)

PI_Administrator (predened)

Results

Your P-user has now access to SAP Cloud Integration.

2.1.4.4 Data Replication Framework

You can use the Data Replication Framework (DRF) to send master and transactional data from SAP S/4HANA

or SAP ERP to SAP Digital Manufacturing for execution using IDocs.

Use

You can use the Data Replication Framework (DRF) to send master and transactional data from SAP ERP or

SAP S/4HANA to SAP Digital Manufacturing for execution using IDocs. An IDoc is a data container with a

standardized structure that is used to exchange data. Several message types (for example, production order

or work center) can be sent from SAP ERP or SAP S/4HANA to SAP Digital Manufacturing for execution using

IDocs.

To control the distribution of messages more precisely, you create replication models in which you can dene

lter criteria for the business objects (for example, production order or work center) to be sent to SAP Digital

Manufacturing for execution.

Note

For more information on the Data Replication Framework (DRF), see ERP-MES Integration (PP-MES).

36

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

General Overview of the Procedure

To use the Data Replication Framework (DRF), you must rst set up ALE communication (Application Link

Enabling), which is the technical basis for data exchange between your systems. You need to dene the

following elements in SAP ERP or SAP S/4HANA:

• Logical systems representing the communcation partners

• Document type (IDoc) and communication protocol

• IDoc message types to be exchanged

• Distribution model to control the distribution of IDoc messages

Note

If you set up the DRF, which is recommended, you don't need to create any distribution model. If you

prefer working only with ALE, then you need the distribution model to control the distribution of IDoc

messages.

After setting up the ALE communication, you can make the necessary congurations for the Data Replication

Framework (DRF) that enables you to send messages in specic business contexts (for example, release of a

production order in SAP ERP or SAP S/4HANA).

To set up the Data Replication Framework (DRF), you need to congure the following elements in SAP ERP or

SAP S/4HANA:

• Assign business object types to your business system

• Replication model that denes which business objects (for example, production order or work center) are

sent to which system

• Filter critera for the replication model that control the distribution of business objects (for example, Plant,

Order Type, or Material as criteria to transfer all production orders belonging to a specic plant, specic

order type, or specic material.)

Overview Setup Steps

To set up the Data Replication Framework (DRF), perform the tasks described in the following topics:

1. Before You Start [page 38]

2. Create Logical Systems [page 38]

3. Assign a Logical System to a Client [page 39]

4. Dening Outbound Communication in SAP S/4HANA or SAP ERP [page 41]

5. Dene Outbound Messages for Partner Systems [page 42]

6. Dene a Distribution Model [page 44]

7. Assign Business Objects to Your Business System [page 46]

8. Dene Replication Models and Outbound Implementations [page 48]

9. Dene Filter Criteria [page 50]

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 37

2.1.4.4.1 Before You Start

Here you nd the requirements that must be met before you can start setting up the Data Replication

Framework (DRF).

To set up the Data Replication Framework (DRF), the following requirements must be met:

• You have the Administrator role for SAP S/4HANA or SAP ERP.

• You have set up a HTTP connection. For more information, see Build HTTP Connection [page 30].

• The following business functions have been implemented in SAP S/4HANA or SAP ERP:

• LOG_PP_MES_INT_01

• LOG_PP_MES_INT_02

• LOG_PP_MES_INT_03

2.1.4.4.2 Set Up Application Link Enabling (ALE)

2.1.4.4.2.1Create Logical Systems

As administrator, you need to create logical systems in your SAP S/4HANA or SAP ERP client to set up the

Data Replication Framework (DRF).

Prerequisites

You have the Administrator role for SAP S/4HANA or SAP ERP.

Context

To use the Data Replication Framework (DRF) for the transfer of master data from SAP S/4HANA or SAP ERP

to SAP Digital Manufacturing for execution, you need to create two logical systems in your SAP S/4HANA or

SAP ERP client. The rst represents your SAP S/4HANA or SAP ERP system, the second your SAP Digital

Manufacturing for execution system.

Procedure

Dene the logical systems.

1. Use transaction BD54 and dene the logical system in the cross-client for SAP S/4HANA or SAP ERP.

38

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Note

Creating a logical system is a cross-client activity, that is, all changes also aect all other clients in the

system. You need the authorization S_TABU_CLI in order to do it.

2. Use transaction BD54 and dene the logical system for SAP Digital Manufacturing for execution.

Add the logical system representing SAP Digital Manufacturing for execution to your ERP system (client) to

ensure the distribution of production orders.

3. Use transaction SPRO and choose SAP Reference IMG.

4. Choose

Production Integration with a Manufacturing Execution System Integrate Production Orders

with a Manufacturing Execution System

Maintain Logical System for Distribution of Production Orders .

5. Choose New Entries to add a logical system.

Example

Plant

Order Type

Determ. Method Logical

System Logical System

<Plant number>, for

example, 1010

<Order type>, for ex-

ample, *

Customizing

Creates Logical

System

Logical System rep-

resenting SAP Digital

Manufacturing for

execution, for example

DMETest

6. Choose Save.

Results

You have created two logical systems representing your source and target system.

2.1.4.4.2.2Assign a Logical System to a Client

As administrator, you need to assign a logical system to a client in SAP S/4HANA or SAP ERP to set up the

Data Replication Framework (DRF).

Prerequisites

• You have the Administrator role.

• You have dened a logical system for the SAP S/4HANA or SAP ERP system using transaction BD54. For

more information, see Create Logical Systems [page 38].

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 39

Context

Setting up the Data Replication Framework (DRF) to enable data exchange between SAP S/4HANA or SAP ERP

and SAP Digital Manufacturing for execution requires you to assign a logical system to your SAP S/4HANA or

SAP ERP client.

Procedure

1. Log on to SAP S/4HANA or SAP ERP as an Administrator.

2. Access the activity using one of the following navigation options:

Option

Description

Transaction code

SCC4

Initial screen of the SAP

system

SAP Menu Tools Administration Administration Client Administration

Client Maintenance

3. On the Display View "Clients": Overview screen, choose Edit.

4. Conrm the information message Caution: The table is cross client.

5. Select your SAP S/4HANA or SAP ERP client (for example, client 100) to be connected to the SAP Digital

Manufacturing for execution system, and choose Details.

6. In the Logical System eld, select the newly created logical system of your SAP S/4HANA or SAP ERP

client using the value help.

7. Choose Save ( Ctrl + S ) and conrm the message Be careful when changing the logical system.

8. Choose Back ( F3 ) twice.

Results

You have successfully assigned the logical system to your client.

40

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

2.1.4.4.2.3Dening Outbound Communication in SAP S/

4HANA or SAP ERP

As administrator, you dene a port for outbound communication, the IDoc format as container for messages

and the SOAP protocol in SAP S/4HANA or SAP ERP to enable data transfer between your system and SAP

Digital Manufacturing for execution using the Data Replication Framework (DRF).

Prerequisites

You have the Administrator role in SAP S/4HANA or SAP ERP.

Context

To transfer master data from SAP S/4HANA or SAP ERP to SAP Digital Manufacturing for execution using the

Data Replication Framework (DRF), you dene a port for outbound communication in SAP S/4HANA or SAP

ERP. Moreover, you choose the IDoc format as a container for your messages and SOAP as protocol for the

data exchange.

Procedure

1. Use transaction WE21.

2. In XML HTTP, choose the RFC destination that you have created using SM59 as described in Build HTTP

Connection [page 30].

3. Choose Application/x-sap.idoc and SOAP Protocol.

4. Choose Save.

Results

You have dened a port for outbound communication.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 41

2.1.4.4.2.4Dene Outbound Messages for Partner Systems

As administrator, you dene outbound messages for partner systems in SAP S/4HANA or SAP ERP to enable

data transfer to SAP Digital Manufacturing for execution using the Data Replication Framework (DRF).

Prerequisites

You have the Administrator role for SAP S/4HANA or SAP ERP.

Context

To set up the Data Replication Framework (DRF) to enable data transfer from SAP S/4HANA or SAP ERP to

SAP Digital Manufacturing for execution, you navigate to the Partner Proles and assign the logical system

representing SAP Digital Manufacturing for execution to the SAP Digital Manufacturing for execution system.

Moreover, you dene outbound message types for the transfer of data from SAP S/4HANA or SAP ERP to SAP

Digital Manufacturing for execution through a synchronized RFC.

Procedure

1. In transaction WE20, choose Partner Type LS.

2. Choose to create a new logical partner system.

3. In Partner No., enter the logical system representing SAP Digital Manufacturing for execution that you have

created under Create Logical Systems [page 38] . Enter US in Ty., <SAP ERP user> in Agent, and EN in

Lang.

4. In the Outbound table, choose Create outbound parameter.

5. On the Partner Proles: Outbound Parameters screen, select Pass IDoc Immediately and Cancel Processing

After Syntax Error, and enter data in the following elds:

Field Value

Message Type BOMMAT

Receiver port HCI_DME

Pack. Size 1

Basic type BOMMAT05

Note

HCI_DME ist just a placeholder for the receiver port, which refers to the port for outbound

communication dened in a previous step: Dening Outbound Communication in SAP S/4HANA or

42

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

SAP ERP [page 41]. You can dene the receiver port's name as you please, but make sure that all

message types dened here have the same receiver port name.

6. Repeat steps 3 and 4 to add the following parameters:

Message Type Receiver Port Basic Type

INVCON HCI_DME INVCON03

LOIPRO HCI_DME LOIPRO05 (production order and

process order)

LOIPLO HCI_DME LOIPLO02 (planned order)

LOIROU HCI_DME LOIROU04

LOIWCS HCI_DME LOIWCS03

MATMAS HCI_DME MATMAS03

CHRMAS HCI_DME CHRMAS05

CLSMAS HCI_DME CLSMAS04

CLFMAS HCI_DME CLFMAS02

EQUIPMENT_CREATE HCI_DME EQUIPMENT_CREATE02

Note

For more information, see Tool In-

tegration [page 168].

Note

For more information on the supported IDoc versions, see 0003050090 .

For more information on how to enable LOIPRO05 version 2, see 3115603 .

Results

You have enabled the data transfer from SAP S/4HANA or SAP ERP to SAP Digital Manufacturing for

execution.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 43

2.1.4.4.2.5Dene a Distribution Model

As administrator, you need to dene a distribution model in SAP S/4HANA or SAP ERP to control the data

transfer between your system and SAP Digital Manufacturing for execution. If you're implementing the data

replication framework, you don't need to perform this step.

Prerequisites

You have the Administrator role for SAP S/4HANA or SAP ERP.

Context

If you're not implementing the data replication framework (DRF), you need to dene a distribution model

in SAP S/4HANA or SAP ERP to control the data transfer from SAP S/4HANA or SAP ERP to SAP Digital

Manufacturing for execution. The distribution model denes which message types can be sent to SAP Digital

Manufacturing for execution.

Procedure

1. Use transaction BD64.

2. On the Display Distribution Model screen, choose Switch Between Display and Edit Mode.

3. Choose Create Model View and enter data in the following elds:

Field Example Description

Short Text DMEModel The name of the model

Technical Name DMEModel The technical name of the model

Start Date The current date

End Date 31.12.9999

4. Choose the model view you created in the Model Views list and then choose Add Message Type. Make the

following entries:

Field Example Description

Model View DEMMODEL Technical

44 PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Sender S4HCLNT100 Your sending logical system.

Receiver DMETest Your receiving logical system. For

more information, see Create Logical

Systems [page 38].

Message Type BOMMAT

5. Choose Continue.

6. Repeat steps 4 and 5 to add the following message types:

Message Type

Description

INVCON Inventory controlling

LOIPRO Production / process order

LOIPLO Planned order

LOIROU Routing

LOIWCS Work center

MATMAS Material master

CHRMAS Characteristic

CLSMAS Class

CLFMAS Classication assignment

Note

To add message type EQUIPMENT_CREATE, in step 4, select the model view you created and choose

Add BAPI instead of Add Message Type. Enter the values described in step 4 for Model View, Sender /

Client and Receiver / Server. Select Equipment in Object / Interface and Create in Method.

7. Choose Save.

Results

You have dened a distribution model.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 45

2.1.4.4.3 Set Up Data Replication Framework

2.1.4.4.3.1Assign Business Objects to Your Business System

As administrator, you assign business objects in SAP S/4HANA or SAP ERP (business system) to SAP Digital

Manufacturing for execution to exchange data using the Data Replication Framework (DRF).

Prerequisites

You have the Administrator role for SAP S/4HANA or SAP ERP.

Context

To transfer data from SAP S/4HANA or SAP ERP (business system) to SAP Digital Manufacturing for execution

using a replication model within the Data Replication Framework (DRF), you need to assign your business

system to a logical system and an RFC destination. Moreover, you need to add business objects to your

business system, so that you can control the distribution of business objects using a replication model within

the DRF.

Procedure

1. Use the DRFIMG transaction and choose Dene Custom Settings for Data Replication Dene Technical

Settings

Dene Technical Settings for Business Systems .

2. On the Change View "Dene Business Systems": Overview screen, choose New Entries.

If you don't use the System Landscape Directory (SLD), an error message may be displayed because the

business system can't be fetched from SLD. In this case, enter your logical system manually and ignore the

error message for manual entry. Press Enter to save your entry.

3. On the New Entries: Overview of Added Entries screen, choose Unicode, and enter data in the following

elds to create a business system:

Field Value

Business System DMESystem

Logical System DMETest (For more information, see Create Logical Sys-

tems [page 38])

46 PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Field Value

RFC Destination DME_INT (For more information, see Build HTTP Con-

nection [page 30])

4. Choose Save.

5. Choose the business system DMESystem you created and double-click Dene Bus.System, BO in Dialog

Structure on the side menu.

6. Choose New Entries and add the following business object types:

Field Value Description

BO Type 97 Production Order

BO Type 92 Planned Order

BO Type 194 Material

BO Type DRF_0043 Characteristic

BO Type DRF_0044 Class

BO Type DRF_0011 Class Assignment

BO Type 223 Production Bill of

Operations

BO Type 493 Work Center

BO Type 467 Goods Movement

BO Type 183 Individual Material

7. Choose Save.

Results

You have assigned your business system to SAP Digital Manufacturing for execution.

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

PUBLIC 47

2.1.4.4.3.2Dene Replication Models and Outbound

Implementations

As administrator, you dene replication models and outbound implementations to control the data transfer

from SAP S/4HANA or SAP ERP to SAP Digital Manufacturing for execution using the Data Replication

Framework (DRF).

Prerequisites

You have the Administrator role for SAP S/4HANA or SAP ERP.

Context

You dene replication models and outbound implementations in SAP S/4HANA or SAP ERP to control the

transfer of business objects from your system to SAP Digital Manufacturing for execution using the Data

Replication Framework (DRF).

Procedure

1. Use transaction SPRO and choose SAP Reference IMG.

2. Choose

Cross-Application Components Processes and Tools for Enterprise Applications Master Data

Governance Central Governance General Settings Data Replication Dene Custom Settings for Data

Replication Dene Replication Models .

3. Choose New Entries and complete the following elds:

Field Example

Replication Model DMEModel

Description DMEModel

Log Days 10

4. Choose Save.

5. Choose the replication model you created and double-click Assign Outbound Implementation in Dialog

Structure on the side menu.

6. Choose New Entries and add the following outbound implementations:

48

PUBLIC

SAP Digital Manufacturing Integration Guide

SAP Digital Manufacturing for execution Integration

Field Value Description

Outbound Implementation 97_1 Production Order via IDoc

Outbound Implementation 92_1 Planned Order (Repetitive Manufac-

turing) via IDoc