PUBLIC

Dr. Gerhard Welker, SAP

June 06, 2019

SAP S/4HANA Cloud

1905 Release Update

2

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

The information in this presentation is confidential and proprietary to SAP and may not be disclosed without the permission

of SAP. This presentation is not subject to your license agreement or any other service or subscription agreement with SAP.

SAP has no obligation to pursue any course of business outlined in this document or any related presentation, or to develop

or release any functionality mentioned therein. This document, or any related presentation and SAP’s strategy and possible

future developments, products and or platforms directions and functionality are all subject to change and may be changed

by SAP at any time for any reason without notice. The information in this document is not a commitment, promise or legal

obligation to deliver any material, code, or functionality. This document is provided without a warranty of any kind, either

express or implied, including but not limited to, the implied warranties of merchantability, fitness for a particular purpose, or

noninfringement.

This document is for informational purposes and may not be incorporated into a contract. SAP assumes no responsibility for

errors or omissions in this document, except if such damages were caused by SAP’s willful misconduct or gross negligence.

All forward-looking statements are subject to various risks and uncertainties that could cause actual results to differ

materially from expectations. Readers are cautioned not to place undue reliance on these forward-looking statements, which

speak only

as of their dates, and they should not be relied upon in making purchasing decisions.

Legal Disclaimer

3

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Welcome

ONE SAP S/4HANA & SAP S/4HANA Cloud Positioning

SAP S/4HANA Cloud for Manufacturing & Supply Chain

▪ Core Processes

▪ Key Highlights

▪ 1905 Release Highlights

Where to go for more information?

Q & A

Agenda

Gerhard Welker

SAP S/4HANA Product

Management

4

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Welcome

ONE SAP S/4HANA & SAP S/4HANA Cloud Positioning

SAP S/4HANA Cloud for Manufacturing & Supply Chain

▪ Core Processes

▪ Key Highlights

▪ 1905 Release Highlights

Where to go for more information?

Q & A

Agenda

5

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

On any Device, use

role based cockpits

with digital assistant

Embedded analytics for

simulation, prediction &

insight-to-action

Machine learning for

automated processing &

decision support

Watch out Inventory

Watch out Procure

Watch out Finance

SAP S/4HANA and SAP S/4HANA Cloud

…will run your business different than before

6

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

PRODUCTION

PLANNING

QUALITY

MANAGEMENT

MANUFACTURING

INSIGHTS

PRODUCTION

OPERATIONS

ORDER &

CONTRACT

MGMT.

INVENTORY

SHIPPING &

TRANSPORT

ORDER

PROMISING

WAREHOUSING

PRODUCT

COMPLIANCE*

PRODUCT

LIFECYCLE

MANAGEMENT*

ENTERPRISE PF.

& PROJECT

MGMT*

PRODUCT

ENGINEERING

PROJECT

CONTROL

COST

MANAGEMENT

TREASURY*

FINANCIAL

ACCOUNTING &

CLOSE

FINANCIAL

OPERATIONS

CENTRAL

PROCUREMENT

PROCUREMENT

ANALYTICS

SOURCING AND

CONTRACT

MGMT

OPERATIONAL

PROCUREMENT

& INVOICE MGMT

SUBSCRIPTION

BILLING & REV.

MGMT.*

Sales & Revenue

Supply Chain

Asset Mgmt.

Manufacturing

R&D Engineering

Finance

Sourcing & Procurement

Service

COMPLEX

MANUFACTURING

CONSTRAINT

BASED

PLANNING

SALES

PERFORMANCE

MGMT

SALES FORCE

SUPPORT

ADVANCED

WAREHOUSING

ADVANCED

TRANSPORTATION

ASSET

OPERATIONS &

MAINTENANCE

ENVIRONMENT

HEALTH &

SAFETY

SERVICE MASTER

DATA MGMT.

SERVICE PARTS

MGMT.

SERVICE

OPERATIONS &

PROCESSES

ENTERPRISE RISK

& COMPLIANCE

ADVANCED

FINANCIAL

CLOSE

COMMODITY

MGMT

MAINTENANCE

MGMT

EXTENDED SCOPE, CONFIGURATION & INTEGRATION

Providing best practices for:

The most comprehensive, intelligent, and fully integrated

Cloud ERP

The most complete, intelligent, and flexible ERP

Enabling in addition:

SAP S/4HANA CLOUD SAP S/4HANA

one codeline

choice of deployment

ONE SAP S/4HANA

7

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA 1809

FPS 00

2018 2019

Q1 Q2

Q1

SAP S/4HANA

Cloud 1808

Q2

Q3 Q4

SAP S/4HANA

Cloud 1811

SAP S/4HANA

Cloud 1902

SAP S/4HANA

Cloud 1908

SAP S/4HANA

Cloud 1905

SAP S/4HANA

Cloud 1911

SAP S/4HANA 1909

SPS 00

Q4

Q3

Yearly innovation cycle

with quarterly SP stacks

Quarterly innovation cycle

Today

SAP S/4HANA 1809

FPS01

SAP S/4HANA Release Strategy

(2018–2019 and definition of deliveries)

SAP S/4HANA 1809

FPS02

8

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Welcome

ONE SAP S/4HANA & SAP S/4HANA Cloud Positioning

SAP S/4HANA Cloud for Manufacturing & Supply Chain

▪ Core Processes

▪ Key Highlights

▪ 1905 Release Highlights

Where to go for more information?

Q & A

Agenda

SAP S/4HANA Cloud for Manufacturing & Supply Chain

Core Processes

10

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP Success

Factors

SAP Ariba

SAP Integrated

Business

Planning (IBP)*

SAP Distributed

Manufacturing -

3D Printing

SAP

Manufacturing

Execution (ME)

SAP Cloud for

Customer

SAP Fieldglass

Interface to

Warehouse

Management

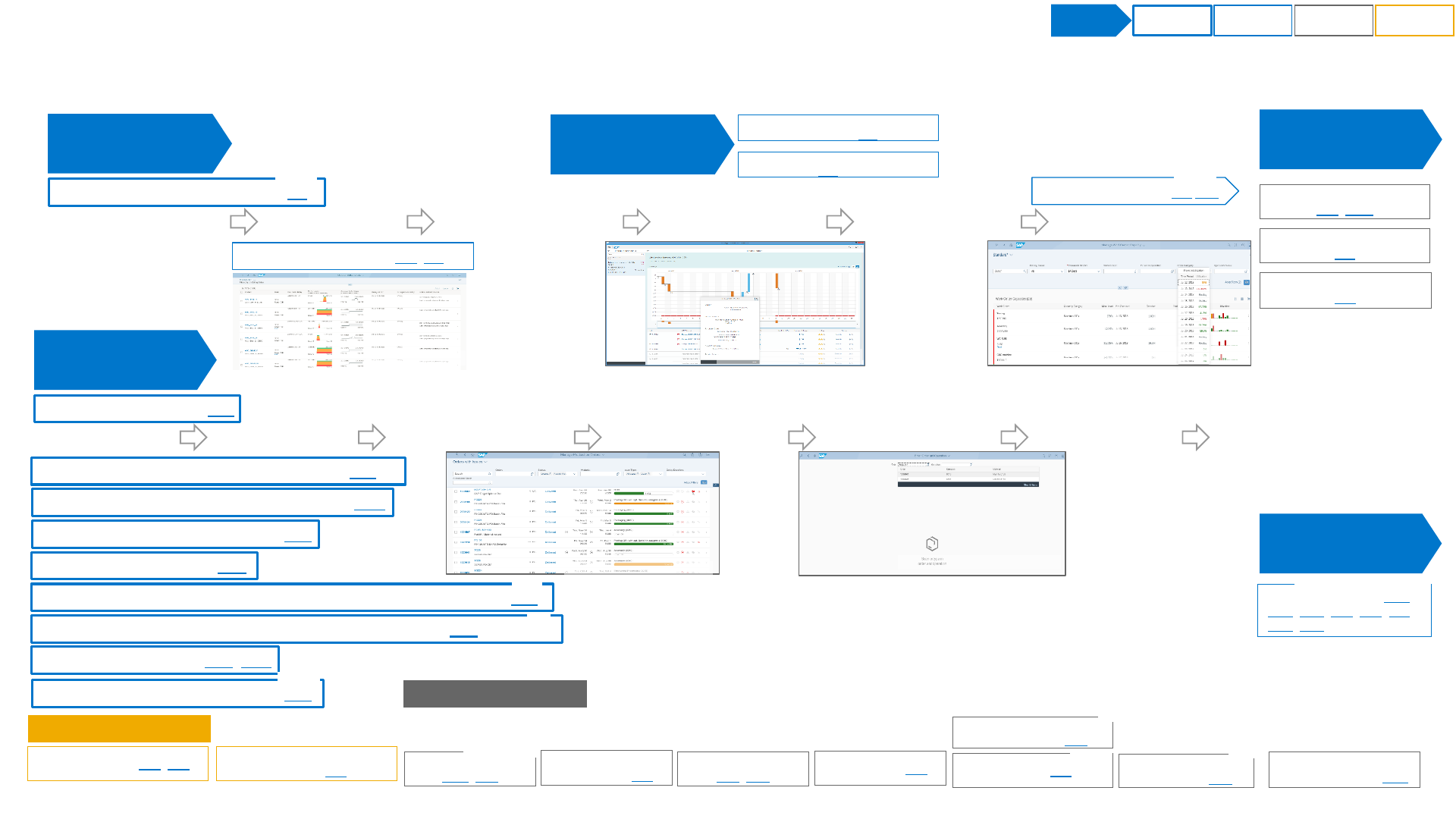

SAP S/4HANA Cloud for manufacturing industries

End 2 End Corporate ERP Processes

Procure to Pay Order to Cash

Production

Execution

Plan to Product

Make to OrderMake to stock

Repetitive

Manufacturing

Business core

Variant Configuration | Inventory Management | Quality Management | Serial Number and Batch Management | Available to Promise

Extend Extend Extend Extend Extend Business core

Extend

Core Finance

Procurement of materials

and services

Manage suppliers and

spend

Production

Planning (MRP)

Forecast

and Demand

Engineering

Sales Order and Contract

Management

Delivery and Billing

SAP Hybris

Commerce

* Roadmap Item

11

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

PRODUCTION

PLANNING

Material Requirements Planning

Capacity Planning

Make to Stock Discrete

Make to Order Discrete

Make to Stock Process

Make to Stock with Variant Config

Make to Order with Variant Config

SAP Analytics Cloud

Manufacturing

Analysis**

MES Integration**

Make to Stock Repetitive

Demand Driven MRP*

QUALITY MGMT.

MANUFACTURING

INSIGHTS

PRODUCTION

OPERATIONS

Batch Management Subcontracting

Subsidiary to

Headquarter

Rework Processing Kanban Supply

Complementary

Procurement Functions

Run Material Requirements

Planning (MRP) to initiate Direct

Procurement & Planned

Production Orders. Plan &

Evaluate Capacity.

Use Demand Driven MRP to

analyze and optimize Stock

strategically

Run Manufacturing Operations

in several industry variations &

extensions, fully integrated with

Supply Chain & Finance

Use Embedded Analytics on

Manufacturing relevant items, like

Stock Overviews, MRP, Capacity

and QM Lists & Dashboards

Use Integrated Quality

Management to plan Inspections,

run checks and improve overall

Manufacturing output.

Process Enhancements Integration scenarios

* Additional license ** Additional License & Installation

Manage Production Orders

Manage Work Center Capacity

Scrap Reason

Monitor Inspection Results

Business

Area

Leading Scope

BP ID#

Supporting

Scope BP ID#

Integration

Item BP ID#

Legend

Scope

Variant BP ID#

PRODUCTION

ENGINEERING

Change Manufacturing BOM

Mass change Manufacturing

BOM

Material: Where used?

SAP S/4HANA Cloud: Manufacturing Scope overview

12

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

PRODUCTION

OPERATIONS

PRODUCTION

PLANNING

Manufacturing Analytics

2JD, 2QW

SAC Manufacturing

Analysis** 28S

Batch Mgmt. BLF

Material Requirements Planning J44

Capacity Planning 31L 3LQ

Make to Stock Discrete BJ5

Make to Order Discrete BJE, 1BM

Make to Stock Process w. Production Order 2UG

Process Enhancements

Make to Stock with Variant Config 21D

Subsidiary to

Headquarter 21T

Rework Processing

BJN, BJQ

MES Integration** 1Y5, 2JN

Make to Stock Repetitive BJH

Quality Management 1MR,

1MP, 1FM, 1E1, 2FA, 2F9,

2QN, 2QP

Report Scrap

BJ5

Demand Driven MRP* 1Y2, 2QI

Integration scenarios

QUALITY MGMT.

MANUFACTURING

INSIGHTS

Complementary

Procure Functions 2TW

Analytical Apps for QM

2V0

* Additional license ** Additional License & Installation *** see slide note on Process Manufacturing

Business

Area

Leading Scope

BP ID#

Supporting

Scope BP ID#

Integration

Item BP ID#

Legend

Scope

Variant BP ID#

Manage Work Center Capacity

Manage Material Shortage

Buffer Positioning

Manage Production Orders

Confirm Production Operation

Run MRP

Create Plan Independent

Requirements

Fix MRP Data issues MRP Evaluation MRP Key figures Create & Evaluate Capacity

Convert Planned to

Production Orders

Stage Material

Manage & Release

Production Order

Pick Components

Confirm Operations

Goods Receipts

Output Mgmt. / Print Label

Make to Stock Process w. Process Order*** BJ8

Change Manufacturing Bill of Material

for Production 3LO

Mass Change Manufacturing Bill of

Material for Production 3LP

PRODUCTION

ENGINEERING

SAP S/4HANA Cloud: Manufacturing Scope in Detail

Update (1MR, 1MP, 2QN)

Make to Order with Variant Config 1YT

update

update

Kanban Supply 1E3

update

update

Subcontracting

BMY, BJK

Update (BMY)

PI- Inbound Storage

Tank Mgmt. 3UK

new

Make to Stock with Co- and By-Products - Process Manufacturing 3L7

new

Make to Stock with Silo Material - Process Manufacturing 3UL

new

Warehouse Kanban

Supply to Prod. 3VT

new

13

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

WAREHOUSING

Warehouse Production Integration 3DV

Third-Party WM System Integr. – Prod. Scen. 2RU

Third-Party WM System Integr. 1ZQ

Goods Issue for Production

• Release production order

• Material staging for production order

Goods Receipt from Production

• Create inbound delivery for production order

• Create handling units, print labels

Support integration scenarios for

• PO processing for semi-finished goods w/o auto. backflush

• PO processing for semi-finished goods with auto. backflush

Business

Area

Leading Scope

BP ID#

Supporting

Scope BP ID#

Integration

Item BP ID#

Legend

Scope

Variant BP ID#

Sales

(Delivery & Return)

Procurement

(Delivery & Return)

Stock

Transfers

Batch Management 2VN

Release Material for Prod.

Warehouse Inbound Processing 3BR

Warehouse Internal Repacking 3BW

Pack stock

Repack stock

Unpack stock

EWM Integration

Del.-Based Production Integr.2VM Outbound Processing 2VK Warehouse Stock Handling 2YL Customer Returns 2VO

Warehouse Ad-hoc Goods Issue 3BT

Warehouse Outbound Processing 3BS

Inbound Processing 2VJ Stock Transport Orders 2VL

Post

goods receipt

Create

putaway warehouse tasks,

print putaway lists

Confirm

warehouse tasks

Pack goods,

print labels

(optional)

Create

pick warehouse tasks,

print picking lists

Confirm pick

warehouse tasks

Post

goods issue

Print loading

instruction

(optional)

Assign

Carrier

(optional)

Quality Management in Warehousing 3M0

Create

Inspection

Lot

Create

Warehouse

Tasks

Record

Inspection

Results

Confirm

Warehouse

Tasks

Make

Usage

Decision

Post Goods Receipt for Production Order

SAP S/4HANA Cloud: Supply Chain Scope in Detail (1/2)

update

update

Resource Management in Warehousing 3W0

new

Just-In-Time Supply to Customer from Stock 2EM

new

Warehouse Kanban Supply into Production 3VT

new

14

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

INVENTORY

Core Inventory Management BMC

Inventory Count & Adjustment BML

Cross-Plant Transfer Posting 1P7

Stock Transfer with & without Delivery BME & BMH

Warehouse Physical Inventory 3BX

Warehouse Posting Changes 3BU

Inventory Actions

• Stock Transfer in one or two steps

• Post Goods Receipt Without Reference

• Block & Unblock Material

• Scraping: Customer Returns and General Stock

Inventory Insights

• Stock Overview

• Material Documents Overview

• Slow or Non-Moving Materials

• Dead Stock Analysis

Inventory Actions

• Create physical inventory documents

• Print physical inventory documents

• Execute physical count or recount

• Enter physical count

• List and post physical count differences

Inventory Insights

• Physical Inventory Document Object Page

• Physical Inventory Analysis

SHIPPING &

TRANSPORTATION

Order-based Transport. Consolidation 3EP

• Create/change SO for automatic freight

unit creation/change

• Monitor freight unit

• Transfer freight unit to decentral. TM

system

• Receive freight order from decentral.

TM system

• Monitor freight order

• Trigger delivery creation from freight

order

ORDER PROMISING

ADVANCED ORDER

PROMISING

Adv. ATP Processing* 1JW

Basic ATP Processing 2LN

• Maintain, schedule, and monitor BOP run

• Run ATP check with product availability check within

e.g. Sell from Stock after sales order creation

• Maintain product allocation and manage product

allocation planning data

• Maintain, schedule, and monitor BOP run

• Run release for delivery to change SO confirmations

before releasing to delivery

• Run advanced ATP check with product availability

check and product allocation

• Perform alternative-based Confirmation (ABC) ATP

Batch Management BLF

Subcontracting BMY

SAP Fiori Analytical Apps for Inventory and Warehouse Management BGG

Business

Area

Leading Scope

BP ID#

Supporting

Scope BP ID#

Integration

Item BP ID#

Legend

Scope

Variant BP ID#

Release for Delivery

Inventory overview

Freight Order List Report

*Additional license - **Additional installation and license

Goods Movement Analysis

SAP S/4HANA Cloud: Supply Chain Scope in Detail (2/2)

update

Predictive Analytics Model

Training: Stock in Transit 20N

update

new

15

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Core manufacturing processes with procurement and sales

16

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Inventory Analyst

• Inventory KPI Analysis

• Inventory KPI Analysis Reuse Library

• Stock Champion

Material Planner - External Procurement

• Create Planning File Entries

• Display MRP Key Figures

• Display MRP Master Data Issues

• Maintain PIRs

UP 1905

• Manage Change Requests

• Manage PIRs

• Schedule MRP Runs

Production Operator / Production Engineer - Discrete Manufacturing

• Confirm Production Operation

• Reuse Library for Components in Worker UI

• Set Kanban Container Status

Production Planner

• Buffer Positioning

• Demand-Driven Replenishment

• Excess Component Consumption

UP 1905

• Manage Buffer Levels

UP 1905

• Manage External Requirements

• Manage Internal Requirements

• Manage Material Coverage

• Manage Production Orders or Process Orders

• Manage Work Center Capacity

• Mass Adjust Buffers

• Mass Maintenance of Products (DD)

• Material Scrap

UP 1905

• Monitor Demand-Driven Replenishment

• Monitor External Requirements

• Monitor Internal Requirements

• Monitor Material Coverage - Net and Individual Segments

• Monitor Material Coverage - Net Segments (obsolete)

• Monitor Material Coverage - Net Segments (Version 2)

• Monitor Production Orders or Process Orders

• MRP Cockpit Reuse Component

• Operation Scrap

UP 1905

• Planned Order Object Page

• Planner Overview

• Process Order Object Page

• Process MRP Simulations

NEW 1905

• Process MRP Capacity Simulations

NEW 1905

• Schedule MRP Simulation Creation

NEW 1905

• Production Execution Duration

UP 1905

• Production Order Object Page

• Resource Object Page

• Schedule Buffer Proposal Calculation

• Schedule Copy Total Forecast Runs

• Schedule Kanban JIT Call Output

NEW 1905

• Schedule Lead Time Classification of Products (DD)

• Schedule Material Demand Forecast Runs

• Schedule Order Conversion Runs

• Schedule PIR Reorganizing Runs

• Schedule Product Classification (DD)

• Schedule Production

UP 1905

• Work Center Object Page

Production Supervisor - Discrete Manufacturing

• Manage Production Operations

• Manage Production Orders

• Manufacturing Planning and Execution Common Reuse Library

• Manufacturing Planning and Execution Reuse Library for Popovers

• Production Order Confirmation Object Page

• Reuse Library for AoR

UP 1905

• Schedule ATP Run for Production/Planned Orders

• Schedule Order Release Run

• Scrap Reason

UP 1905

• Schedule Order Technical Completion Run

Production Supervisor - Process Manufacturing

• Process Order Confirmation Object Page

(business processes within Process Manaufacturing is primarily

supported with Harmoized UI)

Quality Engineer

• Characteristic Analytics

• Characteristic Detailed Analytics

• Manage Control Charts

• Manage Defects

• Manage Quality Info Records

UP 1905

• Manage Quality Levels

• Manage Quality Tasks

• Manage Usage Decisions

UP 1905

• Nonconformance Analytics

• Nonconformance Detailed Analytics

• Quality Engineer Overview

UP 1905

• Quality Level History

Quality Manager

• Inspection Lot Analytics

• Inspection Lot Detailed Analytics

Quality Planner

• Display Quality Info Record for Procurement

• Display Sampling Procedure

• Manage Inspection Plans

NEW 1905

Quality Technician

• Display Master Inspection Characteristic

• Inspection Lot (S/4HANA)

• Inspection Method (S/4HANA)

• Inspection Operation (S/4HANA)

• Inspection Point (S/4HANA)

• Manage Incoming Certificates

• Manage Inspection Lots

• Process Quality Tasks

• Quality Technician Overview

• Record Defects

UP 1905

• Record Defects with SAP CoPilot

• Record Inspection Results

UP 1905

• Record Inspection Results in Table Form

• Record Results for Inspection Points

UP 1905

• Results History

• Reuse Result Recording Library

• Reuse Quick View Library

*Additional license - **Additional installation and license

Exemplary view, most current list see Fiori Apps Library

Delta stickers reflect between 1902 and 1905

SAP S/4HANA Manufacturing: Fiori Apps

17

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

*Additional license - **Additional installation and license

Internal Sales Representative

• Assign Product to Product Allocation

• Configure Product Allocation

• Manage Product Allocation Planning Data

• Manage Product Allocation Sequences

• Monitor Product Allocation Characteristic Value Combinations

• Monitor Product Allocation Order Items

• Monitor Product Allocation Periods

• Product Allocation Overview

Inventory Analyst

• Inventory Analysis Overview

UP 1905

Inventory Manager

• Dead Stock Analysis

UP 1905

• Goods Movement Analysis

• Goods Movement Analysis (Accessible)

• Inventory Turnover Analysis

• Manage Batches

• Manage Stock

• Material Inventory Values - Balance Summary

• Material Inventory Values - Line Items

• Overview Inventory Management

• Physical Inventory Analysis

UP 1905

• Physical Inventory Analysis (Accessible)

• Physical Inventory Document Overview

• Slow or Non-Moving Materials

UP 1905

• Stock - Multiple Materials

UP 1905

• Stock - Single Material

Order Fulfillment Manager

• Configure Alternative Control

• Configure BOP Segment

• Configure BOP Variant

• Configure Custom BOP Sorting

UP 1905

• Configure Order Fulfillment Responsibilities

UP 1905

• Configure Substitution Strategy

UP 1905

• Monitor BOP Run

UP 1905

• Schedule BOP Run

• Schedule Deletion of ATP Results Log

Order Fulfillment Specialist

• Release for Delivery

UP 1905

Plant Manager

• Overview Plant Management

Receiving Specialist

• Expected Goods Receipt

• Inbound Delivery (S/4HANA)

• Schedule Goods Receipt for Inbound Deliveries

• Schedule Inbound Delivery Creation

Shipping Specialist

• Analyze Delivery Logs

• Analyze Delivery Performance - Shipped as Planned

• Create Delivery with Reference to Sales Order

• Create Delivery without a Reference (Quick Create)

• Create Outbound Deliveries - From Sales Orders

• Delivery Performance

• Manage Outbound Deliveries

• Outbound Delivery (S/4HANA)

• Pick Outbound Delivery

UP 1905

• Returns Delivery (S/4HANA)

• Schedule Delivery Creation

• Schedule Goods Issue For Deliveries

Transportation Manager (Transportation Management)

• Create and Update TM Organizations from Enterprise Structure

• Freight Order List

• Freight Unit List

• Manage Freight Agreements

• Schedule Delivery Creation (Transportation Management)

• Schedule Location Creation for plants, shipping points, customers

• Schedule Location Update for plants, shipping points

Warehouse Clerk

• Material Documents Overview

• Material Master Reuse Component

• Overdue Materials - Goods Receipt Blocked Stock

UP 1905

• Overdue Materials - Stock in Transit

UP 1905

• Overview Inventory Processing

• Post Goods Receipt for Inbound Delivery

• Post Goods Receipt for Production Order

• Post Goods Receipt for Purchase Order

• Post Goods Receipt without Reference

• Transfer Stock - Cross-Plant

• Transfer Stock - In-Plant

UP 1905

Warehouse Clerk (Extended Warehouse Management)

• Change Inbound Delivery

• Count Physical Inventory

• Reuse Lib for EWM

• Run Outbound Process – Deliveries

Warehouse Operative (Extended Warehouse Management)

• Pack Outbound Deliveries

UP 1905

• Pack Warehouse Stock

UP 1905

• Process Warehouse Tasks – Picking

NEW 1905

Exemplary view, most current list see Fiori Apps Library

Delta stickers reflect between 1902 and 1905

SAP S/4HANA Supply Chain: Fiori Apps

SAP S/4HANA Cloud for Manufacturing & Supply Chain

Key Highlights

19

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA Cloud

Key highlights in Product Area Manufacturing / Supply Chain

E2E core processes

seamless integrated

with Finance

Production

execution

integration

Demand

Driven

Manufacturing

Advanced

Variant

Configuration

Real time

inventory

management

Integrated

Warehouse

management

20

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Methodology driver: Demand Driven MRP

[Source: Ptak and Smith 2016]

• Permanently optimize the process flow

rather than to plan the forecast

• Produce only for real demand not based on

assumptions

• Work event-driven rather than plan-driven

• Empower teams to make local decisions

instead of to follow a central plan

Highlighting “Decoupling”, “Buffer”, “Lead Times”

Breaking down the overall supply chain at the right spots

Demand Driven Manufacturing

21

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Demand Driven Replenishment

Process Flow

1

2

3

4

5

Replenishment

Planning

Buffer Sizing

(Operational)

Buffer Positioning

(Strategic)

Replenishment

Execution

Individualized

DDR with buffer

Ad-hoc Prod.

Lead time

Var(LT)

Safety stock

Reorder point

t

Material

Stock/

Stock Level

Stock+

Ordered

Propos ed

order qty

FIO-NAV-0815 3 13 30

FIO-PST-1501 6 16 15

FIO-MST-3006 55 135 0

FIO-PRD-0807 22 56 0

FIO-NAV-0101 23 23 127

FIO-NAV-0404 44 44 26

FIO-MST-0821 25 25 0

FIO-PRD-0822 88 88 0

Lead Time

Average Daily Usage

Classification

Analytics

(incl. Basis for Feedback)

22

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Key Trends and Requirements

Serving the “Segment of One”

• From looking at mass customers to

focusing on the single customer’s needs

• Produce for a lot size of one with high

asset utilization and optimal set-up times

Customer centricity

• Customer-driven change towards products

that fit exact needs at competitive prices

• Individualized products are the main

differentiator for winning in the global market

Efficient configuration of sales orders and

more efficient modeling

Product complexity management focus on data

quality, consistency, and agility

Business transparency for configurable products

Coordination and collaboration between sales and

engineering

Simplified, Efficient organization and process

support for engineer-to-order use cases

23

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Disconnected Value Chains and

Multiple Solution/Configuration Models

Seamless Collaboration on One Common

Solution/Configuration Model

Sales

Configurator

(CPQ).

Manufacturing

BOM

Engineering

BOM

As-built/as-

maintained

BOM

Purchased

Parts List

Working Together Seamlessly

Advanced Variant Configuration

Increase Process Efficiency Throughout the Entire Life Cycle

24

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

C/4HANA Configure, Price, Quote

• Consistent Process between Frontend and Backend

• Continue to use your VC configuration models

• Consistent configuration in all channels

• Automatic handover to manufacturing in SAP ERP and SAP

S/4HANA

• Faster GTM strategy - modeling in CPQ

S/4HANA for Advanced Variant Configuration

• Enhanced capabilities to define, develop, sell, manufacture, and

maintain configurable products

• Efficient configuration of sales orders with modern Fiori UX

• More efficient modeling including new simulation environment

• Analytics for configuration and classification data, embedded in

S/4HANA, or in SAP Analytics Cloud

Planned Innovations

Variant configuration and Configure, Price, Quote cover the entire

Digital Configuration Lifecycle

25

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

▪ The variant configuration will be available within SAP S/4HANA on premise and Cloud

▪ Immediately usage of known mature variant configuration LO-VC within S/4HANA on premise

▪ In parallel SAP is building the new advanced Variant Configuration using the same foundation

LO-VC vs. Advanced Variant Configurator

Co-Existence of both solutions

LO-VC

Configurator &

Engine

Configuration Data (cBase)

Master Data VC-Model

On Premise

New Configurator

UI with an new

engine

Within S/4HANA

Cloud exclusively the

new advanced

Variant Configuration

will be available

Cloud Platform

Configuration Data (cBase)

Master Data VC-Model

New Configurator

UI with an new

engine

26

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

New Capabilities:

• Completely new engine for numeric characteristics

• Distinguish between integer and float characteristics

• no decimal places for integers

• mixing integers and floats in dependencies

• mixed restrictions and conditions

• Improved rounding behavior for float characteristics

• Display of both rounded and precise float value

• Represents all master data values exactly

• Support of decimal floating point arithmetic

standard IEEE’754-2008

• Example

0.1 + 0.2 = 0.3 (decimal floating point arithmetic)

vs.

0.1 + 0.2 = 0.30000000000000004 (binary arithmetic)

High precision handling of numeric characteristics

Higher precision of numeric values to improve product configuration accuracy

27

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Simulation Environment – Integration of routing

Improve quality for complex products and product changes by high-efficient simulation of the

routing via different options

New Capabilities:

• Integration of routing with simulation environment

• Structured overview of alternative and parallel

sequences

• Visualization of relationship between BOM and routing

• Routing details are visible in trace and inspector

28

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA Cloud - Warehousing

Inventory

Management

Warehouse Management

Third-Party

Warehouse

Management

System

Ever

Since 1708 Since 1805

Since 1811

EWM

SAP EWM 9.5

EWM

29

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA Cloud Warehouse Management

High Level Scope

Inbound Processing

Internal Processes

Outbound Processing

✓ Inbound from Supplier

✓ Inbound from Customer Returns

(via other storage loc.)

✓ Inbound from other Storage Location

✓ Inbound from other DC / Plant

✓ Inbound from Production

✓ Outbound to Customer

✓ Return to Supplier

✓ Ad Hoc Goods Issue

✓ Outbound to other Storage Location

✓ Ship-to to other DC / Plant

✓ Outbound to Production (Staging)

✓ Outbound triggered by Goods Movement Posting

✓ Physical Inventory

✓ Internal Repacking

✓ Posting Changes (triggered by WM or ERP)

✓ Internal Movements

Warehouse

Structure

Data Migration

Fiori Business

Catalogs /

Roles / Apps

Self-Service

Configuration

UIs

Output

Management

Master Data

Maintenance

Best Practice

Processes

Handling Units in Warehouse Management

Batch Management

30

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

S910

Goods Receipt

SAP S/4HANA Cloud Warehouse Management

Template Warehouse Structure - Enhancement

GR-AREA

S920

Goods Issue

GI-AREA-01

GI-AREA-02

S105

Production Supply

PROD-SUPPLY

S840

Scrapping Zone

SCRAP-AREA

S970

Clarification Zone

CL-AREA

S001

Storage

SF01

Fixed Bin Storage

SB01

Bulk Storage

Template Storage Type

Predefined Storage

Type

Storage Bin

S002

Storage II

SF02

Fixed Bin Storage II

Copy of Template

Storage Type

Master Data

Best Practices Customizing

Customer

Enhancement

S915

Goods Receipt from Production

PR-AREA

SAP S/4HANA Cloud for

Manufacturing and Supply Chain

1905 Release Highlights

32

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA Cloud 1905

Business Area in Line of Business / Industry / Technology

Projects and Engagements

Resource Management

Professional

Services

Controlling and Accounting

Asset

Management

Maintenance Management

Manufacturing

Production Planning

Quality Management

Production Operations

R&D /

Engineering

Product Compliance

Product Engineering

Enterprise Portfolio and

Project Management

Supply Chain

Advanced Order Promising

Product Lifecycle

Management

Project Control

Inventory

Order Promising

Warehousing

Service-Centric Billing

Product- and Asset-centric capabilities Industry-specific capabilities

Real-time foundation

Database and

Data Management

Enterprise Information

Management

Application Platform

and Infrastructure

Foundation

Line of Business /

Industry / Technology

Business Area

Transportation

Nonconformance Management (2QN)

33

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Quality Management

Efficient defect recording with code recognition based on text supported by machine

learning capabilities

With the Fiori app Record Defect, the quality technician can effectively record

defects with high data quality due to the system proposes the best matching

defect codes automatically based on the entered description text using a

predictive analytics model.

Value Proposition

Defect handling supported by machine learning perfectly supports the

quality technician in his daily work

The quality technician can use a Fiori App to record defects. With a mobile

device he can enter a text to describe the defect. Based on text the Fiori

App proposes a defect code which can be assigned to the defect record.

The proposal of defect codes increases the data quality of all recorded

defects. This is important for regular evaluations in order to detect defect

frequency and trigger improvement activities.

Capabilities

Record defective parts or products by a quality technician for example

during production

The defect has to be documented by entering a text and selecting a defect

code

The system proposes the best matching defect codes automatically based

on text using a predictive analytics model

The codes are the basis for later evaluations

This is the current state of planning and may be changed by SAP at any time without notice

and Key innovations do not reflect licensing

34

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA Cloud 1905

Business Area in Line of Business / Industry / Technology

Projects and Engagements

Resource Management

Professional

Services

Controlling and Accounting

Asset

Management

Maintenance Management

Manufacturing

Production Planning

Quality Management

Production Operations

R&D /

Engineering

Product Compliance

Product Engineering

Enterprise Portfolio and

Project Management

Supply Chain

Advanced Order Promising

Product Lifecycle

Management

Project Control

Inventory

Order Promising

Warehousing

Service-Centric Billing

Product- and Asset-centric capabilities Industry-specific capabilities

Real-time foundation

Database and

Data Management

Enterprise Information

Management

Application Platform

and Infrastructure

Foundation

Line of Business /

Industry / Technology

Business Area

Transportation

Material Requirements Planning (J44)

35

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Production Planning

Avoid excess stock with situation handling (MRP Material Exception)

With this feature you can use situation handling in the Manage

Material Coverage app to bring important issues to the users'

attention. Example: In case of a sales order gets cancelled, it is

possible to identify the related MRP Elements such as

production order or purchase order that may already have been

created to fulfill the ‘cancelled’ requirement.

Value Proposition

Situation Handling for Material Coverage

Detect unnecessary supply elements

Capabilities

The following MRP Situations will be detected

No requirements for a receipt element exist. To avoid

unnecessary warehouse stock, the element should be

reversed.

The planned available stock exceeds the maximum stock as

specified.

The actual stock and the receipt elements exceed the

requirements in the individual segment such as make-to-

order planning, individual project planning, direct production

or direct procurement.

SAP Note 2733550

This is the current state of planning and may be changed by SAP at any time without notice

and Key innovations do not reflect licensing

36

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA Cloud 1905

Business Area in Line of Business / Industry / Technology

Projects and Engagements

Resource Management

Professional

Services

Controlling and Accounting

Asset

Management

Maintenance Management

Manufacturing

Production Planning

Quality Management

Production Operations

R&D /

Engineering

Product Compliance

Product Engineering

Enterprise Portfolio and

Project Management

Supply Chain

Advanced Order Promising

Product Lifecycle

Management

Project Control

Inventory

Order Promising

Warehousing

Service-Centric Billing

Product- and Asset-centric capabilities Industry-specific capabilities

Real-time foundation

Database and

Data Management

Enterprise Information

Management

Application Platform

and Infrastructure

Foundation

Line of Business /

Industry / Technology

Business Area

Transportation

Warehouse Kanban Supply into Production (3VT)

Resource Management in WM (3W0) – new in 1905!

Quality Management in WM (3M0)

Warehouse Inbound Processing (3BR)

Warehouse Outbound Processing (3BS)

Warehouse Physical Inventory (3BX)

Warehouse Production Integration (3DV)

Warehouse Ad Hoc Goods Issue (3BT)

Warehouse Posting Changes (3BU)

Warehouse Internal Repacking (3BW)

37

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Warehouse Management

Accelerated and Simplified production supply with harmonized control cycle and

integrated KANBAN processing

In Kanban, a new stock transfer replenishment strategy has

been created, which enables direct warehouse task creation in

Warehouse Management. The tight integration between

warehousing and production reduces the total manufacturing

costs by supporting lean execution principles based on

standardized pull processes.

Value Proposition

Immediate visibility of Kanban replenishment requests in

Warehouse Management

Smoother manufacturing flow

Flexibility in production

Reduce inventory carrying cost

Better-managed inventory levels

Capabilities

Support Kanban scenarios in production supply in

conjunction with Warehouse Management as supply source

Integrated control-cycle maintenance for production and

warehouse functions

This is the current state of planning and may be changed by SAP at any time without notice

and Key innovations do not reflect licensing

38

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

▪ When a kanban container status is

set to "Empty", the Warehouse

Management task is created.

▪ The warehouse task can be

confirmed in two possible ways:

➢User confirms the warehouse task

- the system sets the kanban

container to "Full".

➢User sets the kanban container to

"Full" - the system confirms the

warehouse task

Warehouse Management

Warehouse Kanban Supply into

Production (3VT)

This is the current state of planning and may be changed by SAP at any time without notice

and Key innovations do not reflect licensing

39

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Warehouse Management

Improve efficiency of Mobile execution with new APIs for Warehousing activities

The new scope item Resource Management in

Warehousing (3W0) allows you to leverage interfaces

(APIs) for the development of customer-specific apps for

warehouse task processing on mobile devices. In addition, it

enables you to manage your warehouse resources, such as

a user or equipment that executes work in the warehouse.

A resource is mandatory to process warehouse orders and

tasks with the APIs.

Value Proposition

Increase the efficiency of warehouse processes

Enable customers to manage warehouse resources

Optimize workload for a dedicated warehouse resource

Reduce additional work caused by paperwork

Capabilities

Use Resource Management for mobile warehouse

execution

Integrate with mobile warehouse task processing

Implement customer-specific apps for mobile warehouse

execution for instance via the SAP Mobile Development

Kit

This is the current state of planning and may be changed by SAP at any time without notice

and Key innovations do not reflect licensing

40

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

▪ Leverage interfaces (APIs) for

the development of customer-

specific apps for warehouse task

processing on mobile devices

▪ APIs enabling users to:

➢Process warehouse orders

and warehouse tasks

➢Block warehouse orders and

prevent concurrent processing

by different warehouse

workers

Warehouse Management

Resource Management in Warehousing (3W0)

This is the current state of planning and may be changed by SAP at any time without notice

and Key innovations do not reflect licensing

41

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Our direction

Open warehouse management with

published APIs to allow partners and

customer to consume warehousing data on

any device

Goal for S/4HANA Cloud 1905

• Published API for Warehouse Order /

Warehouse Task processing

• Published API for Resource Management

related functions

Warehouse Management

42

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

• SAP Cloud Platform Mobile Services includes a new

Mobile development kit.

• Empowers developers to build and customize rich,

native extensible mobile applications

• It simplifies the app lifecycle management.

• Creates native apps (SAP Asset Manager is an

example)

• Video Tutorial

What is it?

SAP Mobile Development Kit

43

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP Mobile Services Client App

The SAP Mobile Services Client is a native iOS application that gets its UI

and business logic from JSON metadata. The metadata is defined in a

WebIDE-based editor. It's provided to the client using the App Update service

of Cloud Platform mobile services.

The client connects to mobile services with an endpoint URL among other

properties which are provided by the user. These properties are usually

embedded in a custom URL which is sent to the user’s email. The custom

URL must start with "sapmobilesvcs://".

When the client connects to mobile services, it receives the app metadata

and connects to one or more OData services. OData can be securely stored

locally so that it's available offline. The UI is implemented with the SAP Fiori

framework.

This app is “generic” in that no application definitions or data come with the

app. It’s only usable if the user connects securely to a mobile services

instance.

44

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Runtime – Mobile Services

• Deploy the app via standard Mobile

Services commands from WebIDE

• Lifecycle: the mobile client

application automatically receives

any application updates

on-premise

on-demand

internet

OData Service Provider

MDK Client A

SAP Cloud Platform Connector

SAP Cloud Platform

mobile service for dev & ops

MDK Client B Other Apps

45

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

MDK Prototype on iOS

46

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA Cloud for Manufacturing & Supply Chain

Improve warehouse operative efficiency with new SAP Fiori app “Process Warehouse

Tasks - Picking”

The new SAP Fiori app Process Warehouse Tasks –

Picking enables the warehouse operative to easily

view, print and confirm open picking tasks also on

mobile devices.

Value Proposition

Improve usability and productivity of warehouse

picker

Capabilities

Confirm open picking warehouse task

Confirm picking task with exceptions

Print open picking task

View details of open picking warehouse task

Navigate to product master FIORI app

47

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA Cloud 1905

Business Area in Line of Business / Industry / Technology

Projects and Engagements

Resource Management

Professional

Services

Controlling and Accounting

Asset

Management

Maintenance Management

Manufacturing

Production Planning

Quality Management

Production Operations

R&D /

Engineering

Product Compliance

Product Engineering

Enterprise Portfolio and

Project Management

Supply Chain

Advanced Order Promising

Product Lifecycle

Management

Project Control

Inventory

Order Promising

Warehousing

Service-Centric Billing

Product- and Asset-centric capabilities Industry-specific capabilities

Real-time foundation

Database and

Data Management

Enterprise Information

Management

Application Platform

and Infrastructure

Foundation

Line of Business /

Industry / Technology

Business Area

Transportation

Core Inventory Management (BMC)

48

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Inventory Management

Slow or Non-Moving Materials

The Slow-Moving Indicator enables you to

determine slow-moving materials based on

the consumption to stock ratio. The slow-

moving indicator is an indicator for a slow-

moving material.

This indicator is defined as the total

consumption quantity for the analysis period

divided by the product of stock quantity on

the reference date and multiplied with the

period length in number of days. By taking

time and percentage into account, the result

is normalized and thus makes different

analysis periods comparable.

Monitor materials without consumption (Slow-

Moving Indicator = 0)

A slow-moving indicator = 100 means that 100 %

of the current stock will be consumed within one

year.

49

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP S/4HANA Cloud 1902

Business Area in Line of Business / Industry / Technology

Projects and Engagements

Resource Management

Professional

Services

Controlling and Accounting

Asset

Management

Maintenance Management

Manufacturing

Production Planning

Quality Management

Production Operations

R&D /

Engineering

Product Compliance

Product Engineering

Enterprise Portfolio and

Project Management

Supply Chain

Advanced Order Promising

Product Lifecycle

Management

Project Control

Inventory

Order Promising

Warehousing

Service-Centric Billing

Product- and Asset-centric capabilities Industry-specific capabilities

Real-time foundation

Database and

Data Management

Enterprise Information

Management

Application Platform

and Infrastructure

Foundation

Line of Business /

Industry / Technology

Business Area

Transportation

SAP Fiori Analytical Apps for Inventory

and Warehouse Management (BGG)

50

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Manufacturing & Supply Chain

Ensure inventory accuracy by checking inventory

values as time series for comparable periods

Identify potential outliers that could affect the fixed

capital situation

Display time series as a chart or a table with further

drill-down functionality

Filter for outliers and display only these particular

stocks

The app offers 5 KPI filters that display potential

outliers in a frequency distribution chart for e. g. Stock

Changes, Consumption Changes etc.

Inventory KPI Analysis

Since 1902

51

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Welcome

ONE SAP S/4HANA & SAP S/4HANA Cloud Positioning

SAP S/4HANA Cloud for Manufacturing & Supply Chain

▪ Core Processes

▪ Key Highlights

▪ 1905 Release Highlights

Where to go for more information?

Q & A

Agenda

53

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

SAP

Transformation

Navigator

SAP Transformation Navigator

Supporting your digital transformation

Today

SAP ERP–centric

product map

Future

SAP S/4HANA–

centric product map

Move my landscape

Future product map

Evolve my business

New capabilities

Use a greenfield approach

New digital platform

SAP Transformation Navigator provides you with clear guidance to chart the Intelligent Enterprise:

▪ Based on your currently used products, this free self-service produces an individualized report highlighting business value, detailing integration to SAP S/4HANA

and other cloud products, and explaining transformation services and license information.

▪ With the new time-slider feature, you can even identify the best point in time to engage in your journey to becoming an intelligent enterprise.

▪ Discover the tool and your transformation path at https://support.sap.com/stn.

54

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

• View latest SAP S/4HANA Cloud Release Info

• View upgrade schedule for SAP S/4HANA Cloud

• View SAP service level agreement

• Read about upgrade specific frequently asked

questions

• Continue the conversation and get answers to

your questions in the SAP S/4HANA Cloud

Customer Community

• Sign up to watch other 1905 early release

webinars live or on demand

• Listen to our on demand webinar on how to get

prepared for your quarterly release upgrade

Preparing for 1905: Next Steps

56

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Best Practices

Explorer

Benefit from predefined business processes &

search, browse and consume SAP Best Practices

SAP S/4HANA Cloud Customer

Community

Exclusive for existing customers & partners looking

for deeper product knowledge and expertise

SAP S/4HANA Cloud

Release Info

Latest release highlights including videos and blogs

Where to go for more information?

Learn

Learning Journeys

Learning Room

Stay Current Program

Learn more about digital learning opportunities

SAP Community

SAP Help Portal

Join the SAP S/4HANA

Movement

SAP Transformation Navigator

Roadmap Viewer

SAP S/4HANA Cloud Trial

Engage Implement

Thank you.

Dr. Gerhard Welker

SAP S/4HANA Product Management & Co-Innovation

SAP S/4HANA Cloud for Manufacturing & Supply Chain – The Link Collection

SAP S/4HANA Cloud for Asset Management – The Link Collection

Follow us via @SAP and #S4HANA, or myself via @GerhardWelker and LinkedIn

SAP S/4HANA

Product Jam Group

58

INTERNAL© 2019 SAP SE or an SAP affiliate company. All rights reserved. ǀ

Welcome

ONE SAP S/4HANA & SAP S/4HANA Cloud Positioning

SAP S/4HANA Cloud for Manufacturing & Supply Chain

▪ Core Processes

▪ Key Highlights

▪ 1905 Release Highlights

Where to go for more information?

Q & A

Agenda