NNSA POLICY LETTER

BOP-50.004

Approved: 02-15-08

PROGRAM REQUIREMENTS

DOCUMENT (PRD) FOR

CONSTRUCTION PROJECTS

NATIONAL NUCLEAR SECURITY ADMINISTRATION

Office of Infrastructure and Environment

AVAILABLE ONLINE AT: INITIATED BY:

http://www.nnsa.doe.gov Office of Infrastructure and Environment

BOP-50.004 1

02-15-08

PROGRAM REQUIREMENTS DOCUMENT (PRD) FOR CONSTRUCTION PROJECTS

1. PURPOSE. To establish a National Nuclear Security Administration (NNSA) policy for

developing and maintaining a Program Requirements Document (PRD) on construction

programs/projects being executed by the NNSA.

2. CANCELLATIONS. None.

3. APPLICABILITY.

a. This policy pertains to all projects (except General Plant Projects and Capital

Equipment Projects) constructed for NNSA or managed by NNSA personnel on

behalf of other government agencies with an estimated Total Project Cost (TPC)

great than or equal to $20 million. These projects include: Line Item (Capital)

projects, Operation Expense funded (Op-Ex) projects, and Work For Others

(WFO) projects. Secretarial Officers or their designated Acquisition Executive

may invoke this policy for projects with a TPC less than or equal to $20 million.

b. The Naval Nuclear Propulsion Program and its contractors, are excluded from this

policy, where it is inconsistent with the authority of the Director, Naval Nuclear

Propulsion Program, pursuant to Executive Order 12344, as set forth in Public Law

(P.L.) 98-525, the Department of Energy National Security and Military

Applications of Nuclear Energy Authorization Act of 1985, and P.L. 106-65, the

National Nuclear Security Administration Act.

4. BACKGROUND. This PRD policy establishes the mission and program level requirements

that apply to the development and execution of the program/project. It translates the “need”

in the Mission Need Statement (MNS) into initial top-level requirements addressing such

concerns as performance, supportability, physical and functional integration, human

integration, security, test and evaluation, implementation and transition, quality assurance and

configuration management. Experience has shown that a formal process resulting in an

agreed-upon definition of requirements for new systems, new capabilities, updates, or

enhancements to systems is a prerequisite to proceeding to system/capability design and also

that failure to do this, results in rework and unnecessary costs and delays in schedule. The

intent of this PRD policy is to establish a framework for the development of PRDs for

programs/projects which define the requirements associated with project scope, assumptions

and constraints in more detail than the MNS.

5. POLICY.

a. This policy will be applied in conjunction with and will not supersede any

requirements established in accordance with DOE Order 413.3A.

b. The development and maintenance of the PRD is the responsibility of the Program

Office Program Manager.

2 BOP-50.004

02-15-08

c. The initial approved PRD shall contain as many requirements as can be determined at

the CD-0 stage of the project and they shall be in as much detail as possible. For

illustrative purposes, Attachment 2 of this BOP provides an example of an existing

PRD at the CD-1/CD-2 stage of a project.

d. The initial approved version of the PRD must be completed as part of the CD-0

documentation package and must be placed under configuration management at that

point.

6. REQUIREMENTS.

a. The PRD shall contain both mission and program requirements.

b. The PRD shall establish the basic framework for the acquisition strategy.

c. The PRD shall provide the bridge between the MNS and the more detailed System

Design Description and General Design Criteria.

d. The Program Office shall implement the Mission Need Statement by framing the

mission need in expository language in the PRD.

e. The PRD for a given project will be written utilizing the guidance provided in

Attachment 1. (A sample PRD for the CMRR project is provided as Attachment 2).

f. The PRD represents a formal agreement between the program and the project.

Therefore, it shall be signed by the Acquisition Executive, Program Manager and

Federal Project Director (when designated), at a minimum.

7. RESPONSIBILITIES

. NA-50 is assigned the responsibility to serve as the NNSA cognizant

organization for providing policy and guidance in the area of Program Requirements for

construction projects. The Program Manager provides oversight of the project to ensure goals

and objectives are met, and progress is maintained. The Federal Project Director (when

designated), is responsible to the Acquisition Executive, through his site management chain

for the successful execution of all NNSA construction projects as addressed in DOE Order

413.3A.

8. DEFINITIONS

.

a. Acquisition Executive – the individual designated by the Secretary of Energy to

integrate and unify the management system for a program portfolio of projects, and

BOP-50.004

02-15-08

3

implement prescribed policies and practices. He/she

is

the approving authority for a

project's Critical Decisions, per

DOE 0 413.3A.

b.

Critical Decision - a formal determination made by the Secretarial Acquisition

Executive/ Acquisition Executive at a specific point

in a project's life cycle that allows

the project to proceed to the next phase or Critical Decision.

c.

Program Manager - The individual designated by the Program Secretarial Office

(PSO)

and approved by the Acquisition Executive responsible for the oversight

of

project execution.

d.

Federal Project

Director-

The individual (usually on the site where the project is

being executed) who is responsible to the

AE/PSO, through his site management chain

for the execution

of

the project.

9.

REFERENCES.

a.

DOE Order 413 .3A, Program and Project Management for the Acquisition

of

Capital

Assets,

7-28-2006.

b. Systems Engineering Fundamentals 2001, Defense Acquisition University, Part 2

Chapter 4, Requirements Analysis.

10. CONTACT. Point

of

Contact for Administration

of

this Policy Letter is the Associate

Administrator for Infrastructure and Environment

(NA-50), 202-586-7349.

ATTACHMENT

1.

RECOMMENDED PRD FORMAT AND CONTENT GUIDE.

ATTACHMENT

2.

PROGRAM REQUIREMENTS DOCUMENT.

BOP-50.004 Attachment 1

02-15-08

Recommended PRD Format and Content Guide

Title Page

Identifies the specific project(s), date, revision number, classification and the origin of the

document.

Concurrence/Approval Page

Provides signature and dating space for the federal officials including (at a minimum) the

Acquisition Executive (if not above NA-1), Program Sponsor (e.g., designated PSO Office), the

Program Manager, the Site Manager, and the Federal Project Director. If desired by the Program

Office, an additional concurrence page depicting concurrences from contractor officials and from

non-NNSA offices may also be included.

Configuration Control Log

Provides a short discussion of approved changes made to the PRD. Lists references to applicable

documentation that provide justification for the changes.

Table of Contents

Lists the contents of the PRD and the location of major topics.

Main Body of the PRD:

1. Introduction and Purpose

Provides a discussion of the purpose of the PRD. Explains that the Federal Program Manager has

lead responsibility to develop and maintain the PRD as a controlled document and ensure that the

proposed project solutions will meet the documented program requirements. The intent of the

PRD is to provide a mechanism to document more detail than the MNS that can be used to define

the peogram/project requirements for the project scope, assumptions and constraints.

2. Background (Optional)

Provides any relevant background of the program or project that may improve the reader’s

understanding of the document.

Attachment 1 BOP-50.004

02-15-08

3. Relationship to Mission Need

The MNS should be referenced and a short synopsis of the MNS should be provided. This

discussion should include a brief summary describing how the project, as implemented pursuant

to the PRD, will meet the need identified in the MNS.

4. Mission Requirements Development

Provide a summary discussion of how the requirements were identified or derived. Explanations

of processes, documentation, direction or guidance that govern the derivation or development of

the requirements should be included. Incorporating information by reference is an acceptable

method for providing the development history, where available. The basis for the requirements,

where not obvious, should be traceable to decisions or source documentation. If desired, details

relating to the traceability of requirements may be included in an attachment to the PRD.

5. Program Assumptions, Constraints & Key Interfaces

Documents the critical assumptions, constraints, and interfaces that are germane to the project. If

the project is dependent on, or provides input to, other programs or decisions, the dependencies

should be stated and their relevance and impact explained. Incorporation of information by

reference is acceptable.

Assumptions:

An assumption is a presumed outcome, value or condition whose actual outcome value or

condition cannot be known or controlled by the project. The assumptions need not include

assumptions that are generic inherencies, such as “Congress will provide adequate funding,” or

“The project will conform to applicable rules and regulations” because these assumptions prevail

whether specified or not. Typical valid assumptions include expected outcomes of uncertain

future events that will impact upon the project, such as “The preferred alternative in the Draft EIS

is selected by the Secretary,” or “The research and development activities for the project will

resolve the technical uncertainties for the project’s specialty equipment by FY XX.”

Constraints:

A constraint is an external demand or proscription that limits degrees of freedom to the project on

how it might choose to execute the project. As above, generic inherencies need not be stated.

Constraints might be physical (e.g., “The project must not generate more than X liters of low

level waste per year.”) or administrative (e.g., “The project shall be limited to deploying proven

technologies.”)

Key Interfaces:

BOP-50.004 Attachment 1

02-15-08

The interfaces of the project to other projects and to programs that could impact upon execution

of the project should be identified.

6. Requirements

A. General

• Requirements must be clear, stand-alone statements that are clearly differentiated as

requirements.

• A requirement must be articulated with sufficient specificity that one can make a clear

determination whether the requirement is satisfied or not.

• There must be at least one requirement, but there is no maximum number. A few

requirements would typically be all that would be required to specify the set of mission

requirements.

• Requirements are designated by verbs that compel an action, such as “must,” “shall” or

“will

( )1

.”

• Where useful for understanding or necessary to provide traceability for a requirement,

context or background may be provided to clarify the requirement or why it exists.

• When generating a PRD, the Program Manager should review PRDs for other projects for

commonality and take advantage of lessons learned from other projects. In particular,

many program requirements tend to be of a conformance basis and would thus tend to

apply to multiple projects. Where applicable, use of commonly accepted requirements is

encouraged.

B. Mission Requirements

• The mission requirements shall be the first section of the requirements and segregated

from program requirements.

• Collectively, the mission requirements should be a comprehensive set of WHAT the

project must provide to satisfy the mission need.

• Mission requirements must include the foundational requirements, which would include

answers to the following kinds of questions, as examples:

1 The word “will” can be used in common language to mean different things. In the one case, the term can mean the

result of an expected future action and in the other a demand for a future action. It is the latter usage that applies here.

Where ambiguity might result about using the word “will,” use “shall” whose meaning is unambiguous.

Attachment 1 BOP-50.004

02-15-08

o What functions and capabilities must the project provide?

o What size or capacity is required?

o What schedule demands must the project satisfy?

o What interfaces must the project satisfy?

o Are there any budget limitations?

o Are any requirements unique to this type project?

Examples of valid mission requirements:

* The HEUMF will provide storage for a minimum of 28,000 containers and a

capability for the quantity of HEU identified in Reference X.

* When fully operational, CMRR shall integrate with PF-4 such that the pair of

facilities, along with the supporting infrastructure at or near TA-55, will operate as

a system to meet nuclear mission assigned to LANL.

* The CEF project shall provide the capability to x-ray various size weapons,

including the largest dimensional weapons in the inventory with resolutions

sufficient to verify established weapons certification requirements.

* The RLWTF shall provide the capabilities to process radioactive liquid waste

from the Stockpile Stewardship, Manufacturing, and Related Programs.

Examples of requirements that are not mission requirements:

*The project shall conform to DOE Order 413.3. (Whereas this is a valid

requirement, it is not a mission requirement. The requirement informs how one

executes the project, not what need the project serves.)

*A new building should be provided for the project. (The mission requirements

should specify functions, not architecture. An exception to this would be where

there is an established mandate that a particular architecture is required, such as

might result from a NEPA decision. In such a case, including such as a mission

requirement would be valid.)

*Safety is the number one priority for the project. (Whereas this demand may be

valid for the project, it is an expression HOW the project should be executed, not

what it does.)

*Project systems and equipment should be functionally independent to enhance

system reliability. (This is a design criterion, not a mission requirement.)

In some cases, judgment must be exercised to determine whether a requirement is a mission

BOP-50.004 Attachment 1

02-15-08

requirement or not. For example, consider the case in which a project is expected to provide

its capability for fifty years. If one expresses this as a mission performance requirement

(“The project will provide its services for fifty years to meet the enduring requirements of the

Nuclear Weapons Complex.”), this would be a valid mission requirement. However, one

might express the same intent but use different prose (“The facility shall be designed for a

fifty year design life.”) In this rewrite, the mission requirement is supplanted by a design

criterion, which is not a mission requirement. The Program Manager has the responsibility to

make the judgments about what constitute mission requirements and write them accordingly.

C. Program Requirements

Program Requirements may span a variety of topics and would be project-specific. The

Program Manager should structure them to be logically organized by topic (e.g., safety,

performance, management, environment, or security). The kinds of requirements that might

be included in the program requirements section(s) are discussed below. Many program

requirements are generic, boilerplate requirements that stem from conformance to existing

DOE Orders, policies, and practices and as such they tend to apply to multiple projects.

1. Technical Requirements and Design Criteria

The PSO, as the sponsoring agent, may choose to impose more specific or more detailed

design criteria or technical requirements for the project than would apply if nothing were

specifically identified

(2)

. The additional requirements and criteria that the Program Office

might include in its PRD could relate to the following:

• Operational and Functional Requirements. Define operational and functional

requirements the new capability must provide to satisfy mission need.

• Physical Integration. Define requirements associated with integrating the products of

the acquisition program into the physical environment (e.g., real estate, space,

environment, energy conservation, heating, ventilation, air conditioning, grounding,

bonding, shielding lightning protection, cables, hazardous materials, power systems

and commercial power, telecommunications, special Functional Integration).

• Define functional integration requirements associated with integrating the new

capability into the operational environment.

• Human Integration. Define human-product integration requirements to achieve

optimum performance from a total project perspective. Define requirements related to

employee heath and safety. Define requirements associated with special skills and

capabilities for operators, maintainers, or support personnel.

• Safety and Health. Define high-level safety requirements, which meet the safety goals

determined by the hazard identification process. Include requirements, which may not

relate to specific hazards such as those from standards, laws, regulations, and lessons

learned from similar systems.

Attachment 1 BOP-50.004

02-15-08

• Security. Define requirements relevant to physical security, contractor-unique security,

all information and information systems security, and personnel security.

• Integrated Logistics Support. Define supportability requirements for the following as

appropriate: staffing, supply support, support equipment, technical data, training and

training support.

• Test and Evaluation. Define test and evaluation requirements including mandatory

evaluations of safety, environmental, and energy conservation issues prior to joint

acceptance and inspection. Specify whether independent operational test and

evaluation is required.

Hypothetical examples of technical and design criteria that the PSO might choose to impose

are:

• “The performance margin shall be 10% greater than required by DOE Order 420.1A

for decay heat removal.”

• “The information systems selected by the prime contractor must be compatible with

Government-furnished software.”

• “The floor space for the project shall not exceed 10,000 sq ft.”

• “A tunnel must be built between the two facilities.”

• “Plutonium must be containerized as required by DOE Standard 3013.”

2. Management Requirements:

The Program Office may choose to impose more explicit or more rigorous requirements

on the project than might otherwise be implied by DOE 413.3A, the Federal Acquisition

Regulations FAR, The Life Cycle Asset Management Order or other Orders and directions

that apply to DOE projects generally. Typical Types of management requirements are:

• Quality Assurance. Define quality assurance requirements for such functions as

contractor status reporting, metrics, independent verification and validation, vendor

quality, software development processes.

• Configuration Management. Define requirements for the configuration management of

hardware, software, facilities, data, interfaces, tools, and documentation.

• Environmental. Define requirements to achieve compliance with the National

Environmental Policy Act and other environmental regulations and standards.

• Energy Conservation. Define requirements to achieve compliance with energy and

water conservation mandates of the National Energy Conservation Policy Act.

• Hazardous Materials. Define requirements for the handling, eventual removal,

cleanup, and recycling of hazardous materials.

Management requirements that the Program Office might choose to impose might include the

following kinds of hypothetical examples:

BOP-50.004 Attachment 1

02-15-08

• “All subcontractors shall report to a common Work Breakdown Structure that is

approved by the Program Office.”

• “The management of project X shall be coordinated with projects Y that is being

executed contemporaneously.”

• “The risk management plan shall be linked to the contingency allocation model and

validated against actual experience.”

• “The Preliminary Documented Safety Analysis Document shall be completed three

months in advance of completion of preliminary design.”

• “The project shall develop and maintain a codes and standards management plan that

tracks the application and date of applicability for every referenced technical

standard.”

3. Preferences, Principles, and Goals:

Beyond specific requirements, the PRD affords the PSO the opportunity to state its

preferences, principles, and goals to frame how the project should be executed. A

preference, principle, or goal differs from a requirement in that the demonstration of it

may not be straightforward or binary, the demand is tempered (“should” vs. “shall”), or

the statement is made as an approach versus an established endpoint. That some

preferences may be less rigid than requirements does not imply that their importance is

any less than requirements, as the last example below attests. Examples of preferences

that might be included in a PRD:

• “The project should have a goal that it shall not displace more than Y cubic yards of

excavated soil during construction.” (This statement tells of a preference but does not

explicitly demand a particular outcome).

• “The system must meet its safety design performance requirement in any event, but

the project should minimize the need for actuating safety systems to meet those

performance requirements.” (The latter sentence specifies an approach to minimize,

which is expressed as a preference).

• “Safety of the public shall be the first priority.” (This is a principle. It is not

specifically a requirement since it is not specifically verifiable).

7. Summary or Requirements

A summary of the requirements should be provided, including the list of applicable deliverables

or products that are demanded by the PRD.

8. References

Provides a list of references with document title, origin and date that can be readily associated to

the specific citations in the main body of the PRD.

Attachment 1 BOP-50.004

02-15-08

Appendix I. Mission Need Correlation Matrix. Develop a correlation matrix that maps where

every need in the Mission Need Statement is addressed in the PRD. Use table format.

Need Statement

R

D Section or Sub-Section

Number

Requirement Statement

.

Appendix II. Definitions. Define important non-standard terms used in the PRD.

Appendix III. Acronyms. Define all acronyms used in the PRD.

Appendix IV. Residual Technical Requirements (if any). Specify those final sponsor

requirements that are not intended to be satisfied by the acquisition program approved at

CD-1. Resolving these deferred requirements is the responsibility of the Project Sponsor.

BOP-50.004 Attachment 2

02-15-08

LOS ALAMOS NATIONAL LABORATORY

CHEMISTRY AND METALLURGY RESEARCH

FACILITY REPLACEMENT PROJECT

PROGRAM REQUIREMENTS DOCUMENT

CMRR-PRD-009

REVISION 1.0

November 19, 2004

This is a final draft version of this

document that is being used here

as an example for illustrative purposes.

Attachment 2 BOP-50.004

02-15-08

CHEMISTRY AND METALLURGY RESEARCH FACILITY REPLACEMENT

PROJECT

PROGRAM REQUIREMENTS DOCUMENT

CHAPTER II. Program Requirements Document Change Log

DATE REV PURPOSE PREPARED BY APPROVED BY

2/25/2002 0 Initial Issue, Part of

CD-0 Package

T. Nelson D. Beck, NA-12

10/29/04 1 Revision for CD-1

submittal

P. Rhoads

M. Shoenbauer, NA-12

BOP-50.004 Attachment 2

02-15-08

CHEMISTRY AND METALLURGY RESEARCH FACILITY REPLACEMENT

PROJECT

PROGRAMS REQUIREMENTS DOCUMENT

Revision 1

Approved by:

Dr. Everett Beckner Date

Deputy Administrator for Defense Programs, NA-10

Concurrence by:

Martin Schoenbauer Date

Assistant Administrator for Military Application and Stockpile Operations, NA-12

David Crandall Date

Assistant Deputy Administrator for Research, Development, and Simulation, NA-11

Xavier Ascanio Date

Director

Office of Operations and Construction Management, NA-124

Joseph Gazda Date

Acting Director

Office of Nuclear Weapons Stockpile, NA-122

Patrick Rhoads Date

CMRR Program Manager

Office of Operations and Construction Management, NA-124

Concurrence by:

Attachment 2 BOP-50.004

02-15-08

Juan L. Griego, PMP Date

CMRR Federal Project Director

Los Alamos Site Office, DOE

Submitted by:

Dr. Tim O. Nelson Date

CMR Replacement Project Director

Los Alamos National Laboratory

Classification Review:

B. Melton Date

Authorized Derivative Classifier

CMRR Project

BOP-50.004 Attachment 2

02-15-08

TABLE OF CONTENTS

PROGRAM REQUIREMENTS DOCUMENT CHANGE LOG...................................2

ACRONYMS AND ABBREVIATIONS.......................................................................6

I. INTRODUCTION AND PURPOSE..................................................................9

II. MISSION NEED...............................................................................................9

III. REQUIREMENTS DEVELOPMENT AND USE OF THIS DOCUMENT…....10

IV. PROGRAM ASSUMPTIONS, CONSTRAINTS, & INTERFACES….............11

VI. PROGRAM RISKS & MANAGEMENT..........................................................20

VII. PROGRAM REQUIREMENTS SUMMARY:..................................................20

VII. BIBLIOGRAPHY............................................................................................22

ATTACHMENT I: DISPOSITION OF REV 0 PRD REQUIREMENTS AND BASIS FOR

REV 1 PRD REQUIREMENTS.........................................................................23

ATTACHMENT II: CROSS-WALK TO THE REVISED MISSION NEED

STATEMENT............................................................................................................29

CHAPTER III. ACRONYMS AND ABBREVIATIONS

Attachment 2 BOP-50.004

02-15-08

AB Authorization Basis

AC/MC Analytical Chemistry/Material Characterization

A/E Architect / Engineer

AE Acquisition Executive

AL Albuquerque Service Center

AS Acquisition Strategy

BOA Basic Order Agreement

CD-0 Critical Decision 0 (Approve Mission Need)

CD-1 Critical Decision 1(Approved Alternative Selection and Cost

Range)

CD-2 Critical Decision 2 (Performance Baseline)

CD-3 Critical Decision 3 (Start Construction)

CDR Conceptual Design Report

CFR Code of Federal Regulations

CII Construction Industry Institute

CM Construction Management/Manager

CMO Construction Management Organization

CMR Chemistry and Metallurgy Research Facility

CMRR Chemistry and Metallurgy Research Facility Replacement

CRB Contract Review Board

D/B Design/Build

DBA Design Basis Accident

DNFSB Defense Nuclear Facilities Safety Board

DOD Department of Defense

DOE Department of Energy

EAC Estimate At Completion

ESAAB

Energy Systems Acquisition Advisory Board

ECF Entrance Control Facility

EVMS Earned Value Management System

F&OR Functions and Operating Requirements

FAR Federal Acquisition Regulation

FEMA Failure Effects and Modes Analysis

FFF Fuel Fabrication Facility

FOCI

Foreign Ownership, Control, or Influence

FYNSP Future Years Nuclear Security Program

FIC Facility Incident Command

FITS Facilities Improvement Technical Support Building

G&A General and Administrative

HUB Historically Underutilized Business

INP Integrated Nuclear Planning

BOP-50.004 Attachment 2

02-15-08

IPT

ACRONYMS AND ABBREVIATIONS

Integrated Project Team

ICPP Integrated Construction Program Plan

LASO Los Alamos Site Office

LAC Los Alamos County

LANL Los Alamos National Laboratory

LI Line Item

LIG Laboratory Implementation Guidelines

LIR Laboratory Implementation Requirements

LLNL Lawrence Livermore National Laboratory

M&O Management and Operations

M Million

ML Management Level

MNS Mission Needs Statement

MOX Mixed Oxide

MPF Modern Pit Facility

MSA Major System Acquisition

NA-1 National Nuclear Security Administration

NA-10 Defense Programs

NA-12 Military & Stockpile Operations

NA-54 Office of Project Management and Systems Support

NEPA National Environmental Policy Act

NF Nuclear Facility

NISC Nonproliferation and International Security Center

NMGRT New Mexico Gross Receipt Tax

NMSSUP Nuclear Materials Safeguards and Security Upgrades

NNSA National Nuclear Security Administration

NSSB National Security Sciences Building

OMB Office of Management and Budget

OPC Other Project Costs

OPS Operations Center

ORR Operational Readiness Review

PADNWP Principal Associate Director for Nuclear Weapons Programs

PDSA Preliminary Documented Safety Analysis

PDCS Project Delivery and Contracting Strategy

PED Preliminary Engineering and Design

PEIS Programmatic Environmental Impact Statement

PF/PF-4 Plutonium Facility Building 4 (LANL Security Cat I, Haz Cat 2

Facility)

PHA Preliminary Hazard Analysis

Attachment 2 BOP-50.004

02-15-08

PIDAS Perimeter Intrusion Detection and Assessment System

BOP-50.004 Attachment 2

02-15-08

PL

ACRONYMS AND ABBREVIATIONS

Public Law

PM Project Management

PPEP Preliminary Project Execution Plan

PRD Program Requirements Document

PSO Program Secretarial Officer

RFI Request for Interest

RFP Request for Proposal

RFQ Request for Qualifications

RLUOB Radiological Laboratory/Utility/Office Building

ROD Record of Decision

ROM Rough Order of Magnitude

RTG Radioisotope Thermoelectric Generator

S-1 Secretary of Energy

S-2 Deputy Secretary of Energy

S&S Safeguards and Security

SCC Strategic Computing Complex

SFE Special Facilities Equipment

SMARTS Simple Multi-Attribute Rating Technique With Swing Weights

SNM Special Nuclear Materials

SOW Statement of Work

SSP Stockpile Stewardship Program

SSC Source Selection Committee

SUP LANL’s Supply Chain Management Division

SWEIS Site-Wide Environmental Impact Statement

TA Technical Area

TBD To Be Determined

TEC Total Estimated Cost

TEF Tritium Extraction Facility

Title I Preliminary Design

Title II Final Design

TPC Total Project Cost

TYCSP Ten-Year Comprehensive Site Plan

UBC Uniform Building Code

UC University of California

WBS Work Breakdown Structure

WR War Reserves

Attachment 2 BOP-50.004

02-15-08

CHEMISTRY AND METALLURGY RESEARCH FACILITY REPLACEMENT PROJECT

PROGRAM REQUIREMENTS DOCUMENT

I. Introduction and Purpose

The Program Requirements Document (PRD) for DOE's National Nuclear Security Administration

(NNSA) Chemistry and Metallurgy Research Facility Replacement (CMRR) Project at Los

Alamos National Laboratory (LANL) addresses the tiered, programmatic requirements for the

CMRR. The document builds upon and operationalizes the high-level requirements of the CMRR

Mission Need Statement (MNS). This PRD identifies the National Nuclear Security

Administration (NNSA) missions and programs that the CMRR will serve. The technical,

managerial, and programmatic requirements in this PRD define the expectations for the CMRR

Project at the Headquarters Level. The Federal Program Manager has lead responsibility to

develop and maintain this PRD under change control and ensures that the proposed project

capabilities meet the documented program requirements. The prime contractor (LANL) shall

comply with the provisions in this document, and it shall maintain a strict accounting of how the

requirements in this document are satisfied. LANL is responsible to ensure requirements in this

document flow down to sub-contractors.

Revision 1 (REV 1) of the PRD focuses on engineering, design, management, and planning

requirements, consistent with the stage of the project. Future revisions of this document will add

relevant requirements relating to procurement, construction, operations, and other aspects.

It is noted that the Background (Section II) of the original PRD (PRD-Rev 0) is not included in

Rev 1 for brevity, however, that information remains valid as a foundation for the updated

information contained in this document.

II. Mission Need

The CMRR Mission Need Statement approved with Critical Decision 0 (CD-0) on July 2002 lists

critical NNSA and DOE missions and programs that would be supported by capabilities of the

proposed CMRR. The CMRR Project seeks to relocate and consolidate mission critical CMR

capabilities at LANL to ensure continuous support of NNSA stockpile stewardship and

management strategic objectives; these capabilities are necessary to support current and directed

stockpile work and campaign activities at LANL beyond 2010. This PRD operationalizes the

overall goals in the Mission Need Statement.

BOP-50.004 Attachment 2

02-15-08

III. Requirements Development and Use of this Document

PRD development during the pre-conceptual phase (Rev 0):

NNSA and LANL have undertaken the Integrated Nuclear Capabilities Planning (INP)

activities to assure that actions to upgrade, replace, or refurbish aging nuclear facilities,

such as CMR, are performed in an integrated, coordinated, and cost-effective manner. The

INP activity, with review and input from NNSA, established the specific programs and

missions to be supported by the CMRR. An overall INP mission set was defined, programs

that support the mission set were identified, and the subset of programs and activities to be

supported by the CMRR was subsequently developed.

Workshops involving both LANL and NNSA participants were held to review candidate INP

missions, select a consensus mission set that was consistent with the NNSA Defense Program

guidance (Gioconda, 2001), and review the required capabilities associated with the mission set.

The workshops also focused on the CMRR-its role and required capabilities to satisfy mission

needs, general facility requirements, and a potential site.

LANL performed additional evaluations to prioritize the program support capabilities to be

included in affected facilities, in particular what should be included in CMRR. These evaluations

resulted in a recommended set of core capabilities that should be included in CMRR, as well as a

set of optional capabilities identified for further consideration. (cf Ref 2-6)

PRD development to support preliminary design execution (Rev 1):

During conceptual design phase activities, the INP process was used to review and present

information and results of CMRR conceptual design development, including technical and

programmatic scope options responding to NNSA program direction. INP-driven consensus

recommendations were primary input to NNSA Program Secretarial Officer (NA-10) decision

briefings that produced formalized direction that serves as the basis for CMRR CD-1

recommendations. This Revision of the PRD captures results of decisions made during the

conceptual phase of project development.

Rev 1 of the PRD reflects scope decisions made by DOE in response to the Conceptual Design and

responds to the evolving maturity of the design, structure, and functions for CMRR by the

following:

• Definitizing and, where applicable, quantifying requirements previously specified at

Attachment 2 BOP-50.004

02-15-08

generic levels;

• Reflecting the implementation of CMRR as a phased project with two major facilities and

supporting structures and services;

• Refining and consolidating safety and management requirements;

• Establishing expectations for the design phase for CMRR;

• “Projectizing” requirements to facilitate implementation and tracking;

• Reflecting the missions assigned to CMRR as defined by NA-10 (Beckner, 2004); and

• Distinguishing between mission requirements (those relating to what the project does) and

implementation requirements (those relating to how the project will be executed).

The basis for the Rev 1 requirements and a crosswalk to Rev 0 is provided for information in the

Attachment to this PRD.

Use of the PRD

The PRD is DOE’s link from the high-level Mission Need Statement to the programmatic and

technical documentation that is assigned for the contractor to implement. The PRD is DOE’s top-

level specifications and requirements for CMRR.

The PRD is broken into several sections. The first section, Mission Requirements, corresponds to

the “Technical Scope” Level 0 or Level 1 as defined in DOE Order 413.3, “Program and Project

Management for the Acquisition of Capital Assets.” The other sections correspond to “Technical

Scope” Level 2 requirements. Level 2 changes can be administered at a lower level of authority

than Level 0 and Level 1 requirements.

This PRD specifies a number of deliverables and products that will be generated by the contractor

to meet DOE’s expectations for project execution.

IV. Program Assumptions, Constraints, & Interfaces

There are several key assumptions and constraints that factor into the scope and content of the

program requirements for CMRR. In addition, there are several facilities and projects, both

existing and proposed, whose interfaces with CMRR must be carefully coordinated. A list of the

assumptions

2

and constraints and key interfaces is provided.

2

An assumption is a presumed outcome, value or condition whose actual outcome, value or condition cannot be

known or controlled by the project.

BOP-50.004 Attachment 2

02-15-08

Assumptions and Constraints

• NNSA will ensure availability of budget resources necessary to optimize CMRR project

implementation.

• The CMRR will be located at TA-55 and will consist of Security Category I and

Radiological structures.

• The CMRR project will provide typical infrastructure support: office facilities, roads,

electrical, natural gas, water, sewer, communications, etc, needed specifically for CMRR

facilities and operations. CMRR infrastructure support will require additional LANL TA-

55 site infrastructure improvements that will be provided via other projects/program

activities and require close integration with CMRR (See Key Interfaces below).

• The CMRR project will not address all LANL Hazard Category 3 and 4 space

requirements. For example, CMRR will not accommodate several low material-at-risk

(MAR) and NIS operations currently conducted at TA-48, TA-46, and the existing CMR

Building.

Key Interfaces

Interfaces between the CMRR project and other related projects and activities need to be

monitored and controlled to ensure that no detrimental impacts are forced on one project by

another. This section identifies the known key interfaces to enable effective planning to mitigate

any untoward impacts.

In addition to meeting the higher-level interfaces relating to budgetary planning and processes, CMRR

must interface with the following activities, tasks, and facilities:

• CMR operations and planning, especially for transition to CMRR and for shutdown.

• PF-4 operations, assignment of mission functions between PF-4 and CMRR, and emergent

upgrades.

• LANL Nuclear Facility Consolidation activities and upgrades to facilities and equipment

including the following active/planned activities: TA-18 Critical Experiments Facility

Relocation, Nuclear Material Safeguards and Security Upgrade Project (NMSSUP) Phase-

II, relocation of radiography from TA-8, and the Radioactive Liquid Waste Treatment

Facility (RLWTF) Upgrades Project.

• Interfaces and integration with ongoing and planned TA-55 site programs, actions and

activities, including Safeguards and Security, Safety/Authorization Basis, and site

infrastructure initiatives.

• The user communities to ensure their needs will ultimately be satisfied by CMRR when it

Attachment 2 BOP-50.004

02-15-08

is operational.

V. Program Requirements

Program requirements for the CMRR Project are derived from the mission needs considering the

current configuration of existing facilities, assessments of current facility conditions and

effectiveness, and current and future LANL missions. The following lists the program

requirements for the CMRR project. All requirements are numbered. Other text is provided for

context or for clarity. Attachment 1 provides a crosswalk of program requirements between Rev 0

and Rev 1 of this document

A. Mission Requirements

Requirement P1. Base Nuclear Facility Requirements: The CMRR project shall

provide the following nuclear laboratory and research capabilities to be installed in

the new Nuclear Facility (NF) as detailed in Table I that shall be operational

3

no

later than as specified in the Preliminary Project Execution Plan (PPEP), when

published:

• Facilities and equipment needed to support missions assigned to LANL with nuclear

analytical chemistry and materials characterization operations, including relocating all

mission-essential CMR AC/MC capabilities and associated research and development

space for these functions;

• Facilities and equipment needed to support anticipated CMRR operational and general

LANL long-term special nuclear materials (SNM) storage requirements;

• Facilities and equipment needed to support large vessel handling operations; and,

• Facilities and equipment necessary to support the implementation of the above

requirements into a capable nuclear facility to meet its mission objectives, such as

materials handling, short-term storage, waste management, sample management, and

sample preparation.

Requirement P2: Base Requirements for the Radiological Laboratory, Utility, Office Building:

The CMRR project shall provide the following radiological and non-radiological capabilities in

the new Radiological Laboratory, Utility, Office Building (RLUOB) that will be operational

4

no

later than as specified in the RLUOB Project Execution Plan at CD-2/3, when published:

• A radiological laboratory for conducting up to radiological levels (< 8.4 g Pu239

equivalent) quantities for analytical chemistry, materials characterization, or actinide

research and development;

• Facilities to house utilities for operation of the full suite of CMRR requirements (RLUOB

and NF) including heat supply and heat rejection, water systems, power, communications,

gases, and similar functions;

• Space to support consolidated TA-55 training; and,

• Space for CMRR RLUOB and NF equipment testing, general maintenance, and

3

Pending publication on an approved PPEP, this date is deemed to be the end of FY 2012.

4

Pending publication of an approved PEP, this date is deemed to be the end of 1 Q FY 09.

BOP-50.004 Attachment 2

02-15-08

administrative needs.

Requirement P3: The start of operations in the RLUOB and the NF shall be implemented in

conjunction with the existing CMR and PF-4 operations to ensure continuity of AC/MC services

during operational transition as will be formally agreed to and documented in the CMR-CMRR

transition plan. The CMR-CMRR Transition Plan shall be prepared by the contractor and approved

by the Program Manager as a controlled living document as part of the DOE technical baseline to

detail how the transition will be implemented under a suite of potential transition scenarios.

Requirement P4: The CMRR Project shall be integrated and coordinated with existing and

emergent activities at LANL, and particularly with activities related to Integrated Nuclear

Planning and existing and emergent operations at CMR and PF-4. When fully operational CMRR

shall integrate with PF-4 such that the pair of facilities, along with the supporting infrastructure at

or near TA-55, will operate as a system to meet the NNSA nuclear missions assigned to LANL.

Requirement P5: Specific performance requirements for the base CMRR functions are as follows:

• Analytical chemistry and materials characterization capabilities: CMRR AC/MC

capabilities shall be established to support pit manufacturing and other LANL NNSA

mission activities at rates consistent with level of operations analyzed and established in

the LANL SWEIS.

• SNM storage: Maximum quantity of SNM storage for CMRR operations and LANL long-

term requirements contained with CMRR NF shall be limited to no more than 6 MT Pu239

equivalent to minimize security and safety concerns, material intended for long-term

storage in the long-term storage vault should be containerized.

• Large vessel handling capabilities: The CMRR will provide large containment vessel

handling support for the Dynamic Experiments Program including vessel loading and

unloading operations, and material recovery at a rate of 2 vessels every three years.

• RLUOB:

o The radiological laboratory shall have separable spaces to enable performing

cleared and uncleared work independently.

o Office space for 350 staff members.

o Facilities for consolidated TA-55 training operations, including sufficient space to

support a training staff of approximately 46 people.

o An entrance control facility with underground connecting tunnel that enables access

to the Nuclear Facility.

B. Programmatic Engineering Specifications and Overall Design Principles

Requirement P6: The CMRR shall be designed, constructed, started up, and operated in

accordance with all applicable laws, regulations, DOE orders, and codes and standards.

Requirement P7: Laboratory spaces shall be designed to be flexible and modular to

provide sufficient flexibility to accommodate future changes in mission and the

Attachment 2 BOP-50.004

02-15-08

dynamic conditions associated with normal processing and maintenance activities

in a laboratory environment.

Requirement P8: Systems, structures and components (SSCs) shall be reliable, maintainable, and

inspectable. The design shall maximize the mean time between failures by designing high

reliability into the subsystems. The design shall minimize the mean time to restore system

operations. The CMRR shall be designed for ease of system and unit operations checkout,

maintenance, inspection, and surveillance, and allow ready access to operations and support

equipment. The design of SSCs should maximize passive features, consistent with established

norms and security and safety demands. Major systems should be designed to make them as

functionally independent as practical.

Requirement P9: The CMRR Project structures, systems, and components (SSCs) shall be

designed to support a service life of 50 years. The strategy for achieving a 50-year service life

shall explicitly identify components that are anticipated to require replacement during the

operating life of CMRR. The design shall provide features that enable SSCs to be replaced.

Requirement P10: The CMRR Project shall develop and maintain a program to identify, track and

control technical requirements and directives that emanate from authorities with jurisdiction to

issue such guidance (henceforth referred to as “codes and standards management”). A database of

applicable codes and standards shall be included in a controlled document. The sources of such

guidance include codes, standards, DOE Orders, federal, state, and local laws, rules, and

regulations, this PRD, and provisions in the contract between the University of California and the

Department of Energy, Contract No. W-7405-ENG-36. The codes and standards management

task may be accomplished in conjunction with the Systems Engineering Management Plan, if

desired. The codes and standards management task shall incorporate the following:

• CMRR facilities shall comply with all applicable codes and standards, NNSA

requirements, and applicable NNSA implementation plans for Defense Nuclear Facility

Safety Board (DNFSB) recommendations.

• The facility design shall comply with applicable nuclear facility requirements in Appendix

G of the contract between the University of California and the Department of Energy (UC

Contract Number W-7405-ENG-36).

• CMRR facilities design requirements shall be consistent with those specified in

Modification No. M507, Supplemental Agreement to the contract between the University

of California and the Department of Energy, Contract No. W-7405-ENG-36, Appendix G,

and in the Los Alamos National Laboratory Work Smart Standards.

• CMRR facilities design shall formally consider analogous codes and standards from

industry in accordance with Secretary of Energy guidance memorandum, dated October 31,

2000, to include regulations and guidance documents for commercial nuclear facilities

promulgated by the Nuclear Regulatory Commission.

Requirement P11: CMRR shall be designed in accordance with DOE Order 430.1B,

“Real Property Asset Management” for lifecycle considerations. Effective lifecycle

cost control and asset management shall be a key goal of the CMRR. Technology

BOP-50.004 Attachment 2

02-15-08

and operational practices that can reduce facility lifecycle costs shall be applied

consistent with safety and security requirements.

Requirement P12: CMRR shall be designed to facilitate deactivation, decontamination, and

decommissioning at the end of the facility’s life.

Requirement P13: The CMRR Project design shall use proven technology to the extent

practicable, thereby minimizing engineering and technology development. For gloveboxes, hoods,

and other nuclear specialty equipment, standard design platforms should be selected to minimize

procurement and operational risks associated with acquiring and maintaining an unnecessarily

large number of equipment platforms.

Requirement P14: Prior to Title I design of the CMRR, facility design features pertaining to

meeting safety, security, and quality assurance criteria shall be identified and tracked as part of the

project's technical baseline.

C. Safety Management and Design Requirements

Consistent with DOE Policy P 450.4, the term “safety” as used here “is used synonymously with

environment, safety and health (ES&H) to encompass protection of the public, the workers, and

the environment.”

Requirement P15: LANL shall develop and maintain as a controlled document that is part of the

DOE technical baseline, an Integrated Safety Management Plan (ISM Plan). The ISM Plan shall

include the following:

• That safety of the public and the worker shall be a primary consideration in design,

construction, start-up, and operation of CMRR;

• How the DOE commitments “to conducting work efficiently in a manner that ensures the

protection of workers, the public and the environment” and “to systematically integrate

safety into management and work practices at all levels” are implemented;

5

• How environment, safety, and health shall be integrated into the planning and execution of

all project activities in accordance with NNSA policies for integrated safety management

and NNSA standards for nonreactor nuclear facilities and Integrated Safety Management at

LANL, as defined in IMP-300-00-00.0, “Integrated Work Management for Work

Activities” applicable to where work is being performed;

• How CMRR shall implement a comprehensive safety review process, including input from

self-assessments as well as external independent review groups; and

• How the safety case documents, including the Preliminary Documented Safety Analysis

and the Documented Safety Analysis, will be developed, reviewed, and managed.

Requirement P16: The CMRR project shall provide features and information necessary to support

effective site emergency response actions. Emergency response planning shall be included in the

design phases of the project and shall be coordinated with the existing emergency planning for the

facility site.

5

Both citations are from DOE P 450.4, “Safety Management Policy”, p.1, October 15, 1996.

Attachment 2 BOP-50.004

02-15-08

Requirement P17: Waste minimization shall be a goal of the CMRR. The production of waste

requiring off-site disposal shall be reduced to shall be minimized, consistent with cost-benefit

analyses. The CMRR facilities shall not allow the long-term accumulation of waste and shall

minimize the mixing of radioactive and non-radioactive wastes.

6

Requirement P18: The Nuclear Facility shall be designed to prevent the uncontrolled release of

hazardous material to the environment during all normal and anticipated operations and, to the

extent practical, during, and subsequent to design basis accidents.

7

Requirement P19: The CMRR Project shall comply with Occupational Safety and Health

Administration Process Safety Management Law, 29 CFR 1910.119.

Requirement P20: All areas where a critical mass of material could conceivably amass shall be

designed to be criticality safe under normal operating and design basis accident conditions. The

facility design must meet applicable DOE Order 420.1A and ANSI/ANS 8 series for criticality

safety.

Requirement P21: The CMRR shall comply with the applicable fire protection criteria for

facilities in DOE Order 420.1A.

Requirement P22: Explosion hazards shall be prevented by design to the extent practical. Where

an explosion hazard cannot be precluded by design, mitigative features must be provided to ensure

attainment of the safety requirements specified in this PRD.

D. Integration Requirements

The following requirements are detailed requirements relating to integration of CMRR to the TA-

55 and nearby environs. This section amplifies the overriding integration requirement P4.

Requirement P23: Shipment to and receipt of nuclear and possibly other materials shall emanate

from PF-4. The CMRR project will provide a means to provide safe and secure transfer of SNM

between the two facilities, such as a tunnel.

Requirement P24: The CMRR Project shall be integrated with other ongoing programs’ milestones

and activities in order to minimize the impacts on the objectives of all programs. The design and

construction sequencing shall include provisions to achieve this objective. The other ongoing

programs shall specifically include all Integrated Nuclear Planning activities at LANL, operations

at PF-4, and operations at CMR.

E. Protection of SNM and sensitive information

6

The last part of this requirement duplicates a requirement in DOE Order 420.1A but is included here for

completeness.

7

Short transients, SUCH AS THOSE relating to fan and/or damper evolutions, shall not be deemed to be

“uncontrolled” in applying this requirement.

BOP-50.004 Attachment 2

02-15-08

Requirement P25: The CMRR project shall have an Integrated Safeguards and Security Plan as

part of the DOE-NNSA planning baseline that specifies:

• How the CMRR Project shall protect sensitive information, whether classified or not, in

accordance with applicable directives. Sensitive information includes but is not limited to

business- and procurement-sensitive information, official use only information,

unclassified controlled nuclear information, and classified data.

• How the project will integrate the physical protection for CMRR with the balance of TA-

55 and LANL consistent with DOE Design Basis Threat (DBT) requirements and

implementation plans.

• How design reviews the approval processes will be planned to ensure physical safeguards

and safeguards provisions are considered in the design processes and to ensure timely

approval of design products and information.

• How design concepts at other nuclear facilities, such as HEUMF and the PDCF, might be

considered in the CMRR development processes.

• How DOE Policy 470.1, Integrated Safeguards and Security will be implemented for

CMRR.

Requirement P26: The CMRR facilities shall incorporate physical protection measures necessary

to prevent the theft or diversion of fissile materials consistent with applicable regulations.

Security requirements for protecting Category I and II SNM include DOE O 5632.1 C, DOE M

5632.1 C-1, DOE O 474.1, and DOE M 474.1-1.

Requirement P27: The CMRR facilities shall incorporate material control and accountability

measures necessary to detect the prompt loss of material and to monitor accretion of material

unaccounted for. A near real-time inventory management system is preferred.

Requirement P28: The CMRR NF shall be contained within the Perimeter Intrusion Detection and

Assessment System at TA-55 and incorporate safeguards and security protection strategies

consistent with PF-4. The construction and startup operations of CMRR must be coordinated with

PF-4 and the Nuclear Material Safeguards and Security Upgrade Project Phase II to ensure CMRR

activities proceed in a timely manner without challenging the integrity of the operating PIDAS

already in place.

F. Management

Requirement P29: The CMRR shall have a Systems Engineering Management Plan maintained

under the prime contractor’s technical baseline and concurred in by DOE that:

• Identifies how the engineering process is established and managed, including how

oversight and integration of efforts by sub-contractors is effected and how value

engineering is embedded into the processes;

• Establishes the hierarchy of technical documents and demonstrates how requirements are

flowed down from DOE and from the prime contractor’s requirements documents to lower

level documents;

• Describes how the design basis is developed and maintained;

Attachment 2 BOP-50.004

02-15-08

• Explains how plant or facility wide level requirements are allocated down to SSCs;

• Establishes and maintains the data base that cross-walks commitments for SSCs that are

made in the safety case against design features to meet them.

Requirement P30: Project management systems shall conform to DOE Order 413.3, “Program and

Project Management for all Acquisition of Capital Assets,” as required. Furthermore, the prime

contractor shall develop and maintain an integrated resource- loaded schedule for all phases of the

project (henceforth: Integrated Project Schedule (IPS)) as a living document. The IPS shall be

used for planning, reporting and monitoring. It shall be linked to a central Work Breakdown

Structure that the contractor and all sub-contractors conform to, the project’s cost and schedule

baselines, the earned value management systems, and the risk management systems.

Requirement P31: The CMRR Project shall implement a quality assurance program appropriate for

design and construction of a nuclear facility as defined by DOE/UC Contract W-7405-ENG-36,

Appendix G. The program shall meet applicable quality assurance requirements and shall be

consistent with established quality management processes at LANL. Procurement activities must

be conducted in accordance with the applicable LANL procurement QA requirements.

Requirement P32: A formal Risk Management Plan shall be developed early in the Conceptual

Design Phase of the project to evaluate the potential impacts of each identified risk and to develop

specific risk mitigation/management strategies. The plan shall identify responsibilities for

handling risks and the schedules for their disposition. The plan shall be maintained as a living

document during the life of the project.

Requirement P33: The CMRR Project shall be executed in compliance with configuration

management and change control procedures at LANL. A records management system consistent

with the requirements for design, startup, and operations of a nuclear facility shall be maintained.

All design documents shall be revised to reflect “as-built” condition before project turnover.

Requirement P34: The CMRR project shall support and participate in NNSA programmatic

activities designed to drive information exchange, sharing of lessons learned, and development of

consistent technical/managerial approaches for nuclear facility construction activities. This

includes actively seeking opportunities to participate in information exchange forums involving

other DOE/NNSA large nuclear projects such as the Pit Disassembly and Conversion Facility,

Highly Enriched Uranium Materials Facility, the Mixed Oxide Fuel Fabrication Facility, TA-55

Reinvestment Project(s), and general LANL Integrated Nuclear Planning activities.

G. Other Requirements

Requirement P35: The M&O Contractor shall ensure flow-down of these requirements as

necessary to meet CMRR objectives in all sub-contracts.

Requirement P36: The CMRR Project construction activities shall be performed using technically

acceptable and cost-effective methods and practices. Thorough and comprehensive integration of

construction requirements shall be included throughout the design process.

Requirement P37: Training plans for the CMRR shall support necessary skills development for

BOP-50.004

02-15-08

Attachment 2

design, construction, and operation. Prior to operation, the training plans shall include the type,

amount, and content of training required for personnel operating, maintaining, visiting and/or

inspecting the facility.

CHAPTER IV. VI. Program Risks & Management

Information relating to project risks and management are included in the Project Risk Management

Plan, as invoked by Requirement P32 above.

CHAPTER V. VII. Program Requirements Summary:

PRD, Rev 1, derives from Revision 0. Rev 1 establishes DOE/NNSA expectations for the

contractor to satisfy during the planning, engineering, and Preliminary Documented Safety

Analysis phase of the project. Later revisions will be prepared to address procurement,

construction, start up, and operations when ripe. The principal contents in Rev 1 of the PRD

include:

− Establishing the technical requirements at the Level 0 and Level 1 levels for conformance

with DOE Order 413.3.

− Establishing the high-level Level 2 technical, programmatic, and performance criteria for

CMRR.

− Defines expectations for certain deliverables that DOE considers vital to the execution of

the project.

• The CMR-to-CMRR Transition Plan

• The Codes and Standards Management Plan, including its Non-Conformance Log

• Integrated Safety Management Plan

• Integrated Safeguards and Security Plan

• Systems Engineering Plan

• Integrated Project Schedule

• Risk Management Plan.

Attachment 2 BOP-50.004

02-15-08

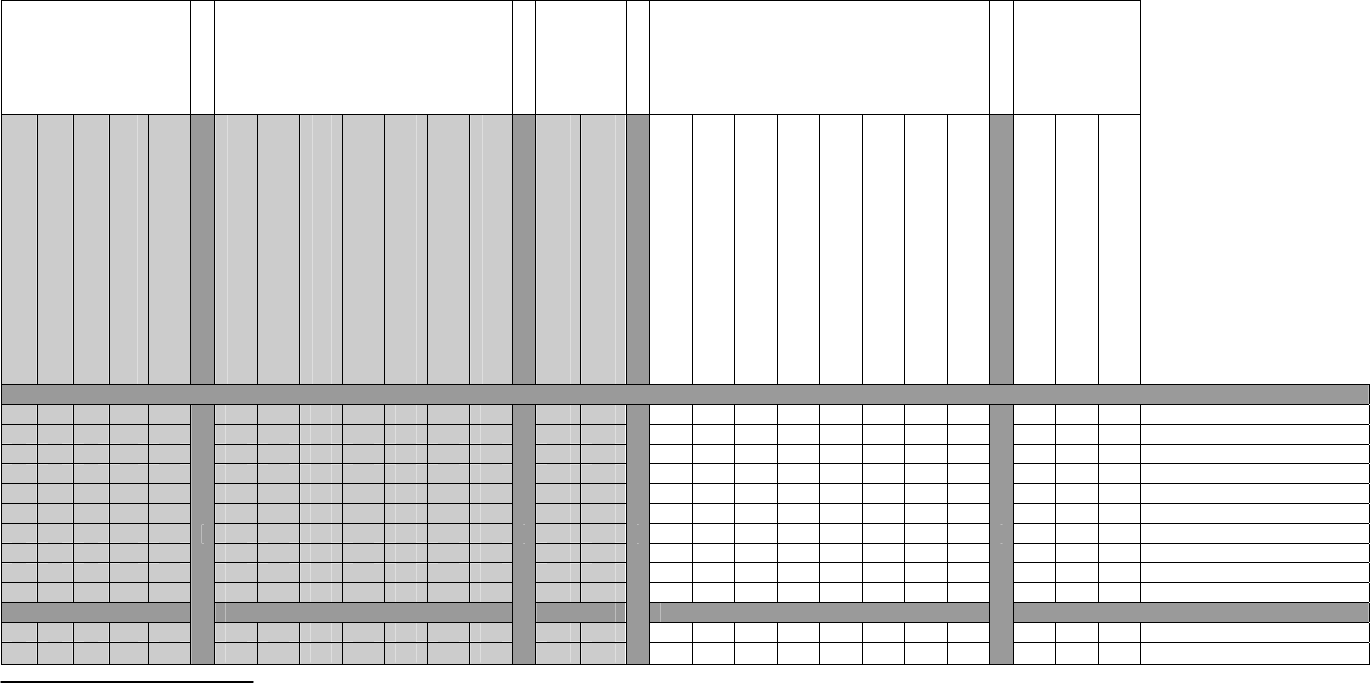

Table 1 Programs Supported by CMRR Functional Capabilities (highlighted in gray)

Directed Stockpile

Work (DSW)

7

Campaigns

7

Readiness

in

Technical

Base &

Facilities

(RTBF)

Non-DP Programs

8

Additional

Programs

8

(non-Pu

Strategies)

Pit Surveillance (15 ppy)

mW RG Surveillance

Special Recovery Line (SRL)

Plutonium Measurements/AGEX

Subcritical Experiments (1–4 expt./y)

Pit Manufacturing (20 ppy)

Material Readiness (20 ppy)

Enhanced Surveillance

Primary Certification

Dynamic Materials Properties

Advanced Radiography

Certification in Hostile Environments

Materials Recycle and Recovery

Materials Storage

Pit Disassembly & Conversion

Plutonium Immobilization

Arms Control and Nonproliferation

Nuclear Materials Stewardship

Nuclear Materials Stabilization

Nuclear Materials – Focus Area

Offsite Source Recovery Program

Heat Source Program

Advanced Fuels

HEU Support

WIPP Characterization Work

Analytical Chemistry and Material Characterization Capabilities

X X X X X X X XX Assay

X X X X X X X X X X X X X X X X X Isotopic/MS

X X X X X X X X X X X X X X X X X Trace Elements

X X X X X X XRF/XRD

X X X X X X X X X X X X X X Radiochemistry

X X X X X X X X X X X Analytical Chemistry

X X X X X X X X X X X X Materials Characterization

X X X X X X X X X X X X X X X X X X X X Sample Management

X X X X X X X X X X X X X X X X X X Standards and QC

X X X X X X X X X X X X X X X X X X X Waste Acct./Handling

Other Capabilities

X X X X X X Large Vessel Handling

X X X X X

X X X X X X

X X

X X X X X X X X

X X

Nuclear Materials Storage

7

As a minimum, CMRR will support AC/MC requirements for the programs listed in the shaded region of this table. Additionally, CMRR could potentially support higher throughput for programs like

Pit Manufacturing and Pit Surveillance if sampling requirements are reduced below December 2004 levels as described in the Analytical Chemistry and Materials Characterization Task Team

Preliminary Recommendations Letter (LANL Memorandum 05-CMRR-008, dated December 7, 2004).

8

Non-DP/Additional Programs evaluated during Pre-conceptual INP Workshops (circa 2001) are shown in unhighlighted portion for historical context only.

CMRR capacities are not being developed to include support for these missions; however, these programs could be supported if AC/MC capacities are available.

BOP-50.004 Attachment 2

02-15-08

CHAPTER VI. VII. Bibliography

1) NNSA/DOE Guidance Memo. Thomas F. Gioconda, Brigadier General, USAF, Acting

Deputy Administrator for Defense Programs, Memo: Defense Programs Guidance on

Integrated Planning for Los Alamos National Laboratory Nuclear Mission Capabilities and

the Chemistry and Metallurgy Research Replacement Project, dated April 6, 2001.

2) Integrated Nuclear Capabilities Planning: Implementation Plan for Upgrades and

Consolidation of LANL Actinide Chemistry and Materials Engineering Facilities, Volume 1:

Mission Set Document, Los Alamos National Laboratory, LA-CP-01-250 (OUO), July 2001.

This document describes the process used to develop LANL Integrated Nuclear Planning

Mission Set and Mission Capacity Factors. The CMRR Project is scoped consistent with the

mission capacity factors agreed upon at the Joint DOE/LANL Workshop #1.

3) Workshop Briefing Materials (OUO/UCNI). Workshop #1 held April 18, 2001, Workshop

#2 held July 11, 2001, both at DOE/AL.

4) Options to Provide Facilities for Actinide Analytical Chemistry, Metallography, and

Materials Characterization in Support of Ongoing Defense Missions, DRAFT, Los Alamos

National Laboratory, (UCNI), December, 2000.

5) “Integrated Nuclear Planning Infrastructure Development Project (U), Utility Systems and

Parking Report,” DRAFT, JCNNM, October 2001.

6) Analytical Chemistry Processes for Pit Manufacturing Mission, LA-UR-97-1898, September

1997.

Minimum Analytical Chemistry Requirements for Pit Manufacturing at Los Alamos National

Laboratory, LA-13482-MS, August 1998.

7) Memorandum from Everet Beckner, Deputy Administrator for Defense Programs, to Ed

Wilmot and G. Peter Nanos, issued September 30, 2004. Subject: Programmatic Direction

regarding Critical Decision-1 (CD-1) planning for the Chemistry and Metallurgy Research

Building Replacement (CMRR), Los Alamos National Laboratory (LANL).

Attachment 2 BOP-50.004

02-15-08

Attachment I: Disposition of Rev 0 PRD Requirements and Basis for Rev 1 PRD

Requirements

The Rev 0 Requirements specified NA-10’s (Defense Program’s) requirements at the time CD-0

was rendered in order to frame the project and set the immediate expectations for the Conceptual

Design Phase as well as provide an outline of expectations for beyond the immediate phase of

the project. The Rev 0 requirements have been updated as a result of completion of the

conceptual design phase and receipt of additional NA-10 programmatic guidance. Program

approved changes to the original (Rev 0) version of the PRD are reflected in Rev 1.

This attachment is provided to document traceability between Revisions. It is provided as

information. This attachment will be removed from future versions of the document and is not

considered part of the document with respect to any authority to define requirements. The

discussion included in this attachment is meant to be a high level discussion of the salient

changes between revisions. No attempt is made here to be a comprehensive, word-by-word

history of the PRD text changes. The discussion here is limited to the changes in the numbered

requirements with its referenced material only and not in the other textual data in the PRD.

Two tables are provided to inform the crosswalk to the Rev 0 to the Rev 1 requirements and also

to understand the origins of new requirements.

BOP-50.004 Attachment 2

02-15-08

Table 2 Mapping of Rev 0 PRD Requirements to Rev 1 of the PRD

Rev 0

Requirement

#

Location

in Rev 1

Rationale and commentary where necessary to describe the

disposition of the old requirements

1 1 The new requirement embeds much of the original in meaning with

the following additional features: (1) the mission schedule is

included in the new requirement; (2) the evolution to a two-facility

project is reflected; (3) the scope of the project is definitized with

respect to PF-4 consolidation, contingency space, large vessel

handling, and SNM storage.

2 1 and 2 The new requirement reflects the evolution to a two facility project,

definitizes the imperative to maintain AC/MC capabilities, and

defines the expectations and deliverable for ensuring continuity of

mission support during the CMR-to-CMRR transition.

3 Deleted No contingency space will be provided in the NF.

4 7 Previous requirement for flexibility is assigned to the NF and the

RLUOB.

5 1 and 2 Differences are partly editorial and partly reflective of the evolution

in Rev 1 to a more performance-based specification of the

requirements, based on the evolved maturity of the project.

6 1, 2 and 4 The new requirements are organized more along functional lines

and are therefore editorially different. The new requirements

precisely describe the desired end state for CMRR when

operational with PF-4, which was not specified previously.

7 1 and 17 None required.

8 10 and

15

The original requirement calls out directives in a piece meal

fashion. The new one incorporates directives more categorically.

The new requirement also establishes expectations and deliverables

for implementing a directives task, an element not included in the

original.

9 10, 15

and 19

See commentary RE: Rev 0 #8.

10 15 The original requirement is very general. The new requirement

embeds the original but also establishes the expectations and

deliverables for implementing the requirement. The new

requirement also formally links to DOE policies with respect to

safety management.

11 25 None required.

Attachment 2 BOP-50.004

02-15-08

12

25-27

The new requirements convey the spirit of the original but the new

requirements: (1) distinguish between safeguards and security; (2)

embed the security orders call outs into the requirement, which

were previously included within the introductory text of the

document; and (3) call out inventory management control

specifically in the new requirement, unlike the original.

13 20 The new requirement applies to all areas where a critical mass of

fissile material might accumulate.

14 4, 23 and

24

The old requirement is expanded consistent with the evolved

maturity of the project. The new requirement #4 also clarifies how

CMRR and PF-4 ultimately will interact and integrate.

15 4 and 24 None required

16 4 and 27. None required.

17 33 None required.

18 9 None required.

19 10 See commentary on old requirement #8.

20 10 See commentary on old requirement #8.

21 36 None required.

22 16 None required.

23 5 None required.

24 10 None required.

25 5 and 10 None required.

26 11 The new requirement embeds the meaning of the old requirement in

the context of DOE Order 430.1B

27 12 None required.

28 10 None required.

29 none Old requirement is now overcome by events and is now deleted.

30 30 The new requirement is more explicit in clarifying how a set of

project management tools need to work together.

31 13 None required.

32 31 None required.

33 5 and 10 None required.

34 8 and 11 The new requirement captures the older requirement but embeds it

in the broader overlay of DOE Order 430.1B, which superceded

DOE Order 430.1A.

35 32 The new requirement also establishes that the Risk Management

Plan is a living document, rather than a point-in-time assessment

tool.

36 37 None required.

37 17 None required.

BOP-50.004 Attachment 2

02-15-08

38 15 None required.

Before addressing specific changes that are made on a requirement-by-requirement basis, the

significant changes in Rev 1 are as follows:

ο Editorial reasons: (1) In the current version all of the requirements are specifically

included in numbered requirements. In the original version, ambiguity existed regarding

whether non-numbered text was descriptive material or requirements. (2) Organization:

The older version scatters related requirements across the document. The revised structure

lumps like requirements for ease of review and comprehension.

ο Requirements specification: The revised version of the requirements tends to be

performance-based.

ο Mission requirements: The mission statement for the CMRR project is more tightly refined

now than when Rev 0 was prepared. The focused mission is now reflected in the PRD.

ο Two facility project: The current Rev reflects the two facility concept for the CMRR

project.

ο Codification of expectations into deliverables: This feature does not exist in the earlier

version. The consolidation of a technical directives task is a good example of this

(Requirement #10).

The rationale for new requirements or changes to existing requirements is reflected in this table.

The crosswalk to original requirements follows from Table A above. For example, Requirement