FactoryTalk Historian Machine

Edition Series B Configuration

Guide

Catalog Number 1756-HIST2G Series B

User Manual

Original Instructions

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and operation of this equipment before you install,

configure, operate, or maintain this product. Users are required to familiarize themselves with installation and wiring instructions in addition to requirements of all

applicable codes, laws, and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are required to be carried out by suitably trained

personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables and requirements associated with any particular

installation, Rockwell Automation, Inc. cannot assume responsibility or liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc., is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING: Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to personal

injury or death, property damage, or economic loss.

ATTENTION: Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT: Identifies information that is critical for successful application and understanding of the product.

These labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash

will cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and for

Personal Protective Equipment (PPE).

The following icon may appear in the text of this document.

Tip: Identifies information that is useful and can help to make a process easier to do or easier to understand.

Rockwell Automation recognizes that some of the terms that are currently used in our industry and in this publication are not in alignment with the movement toward

inclusive language in technology. We are proactively collaborating with industry peers to find alternatives to such terms and making changes to our products and content.

Please excuse the use of such terms in our content while we implement these changes.

2 1756-UM106H-EN-E - June 2024 Rockwell Automation, Inc.

Contents

Overview................................................................................................................................................................................................................................................. 13

Features...................................................................................................................................................................................................................................................................................13

Benefits....................................................................................................................................................................................................................................................................................14

Distributed FactoryTalk Historian architecture................................................................................................................................................................................................................14

FactoryTalk and Logix integration......................................................................................................................................................................................................................................15

FactoryTalk licensing............................................................................................................................................................................................................................................................ 15

License points for the data transfer.......................................................................................................................................................................................................................16

FactoryTalk Historian ME product number....................................................................................................................................................................................................................... 16

Hard disk................................................................................................................................................................................................................................................................................. 16

Before you begin....................................................................................................................................................................................................................................................................16

Additional resources..............................................................................................................................................................................................................................................................17

Get started..............................................................................................................................................................................................................................................18

System connectivity.............................................................................................................................................................................................................................................................. 18

Software and hardware requirements for FactoryTalk Historian ME...........................................................................................................................................................................19

Upgrade or reinstall the firmware......................................................................................................................................................................................................................................19

Differences between upgrade and reinstallation.................................................................................................................................................................................................20

Collect the module-related information.................................................................................................................................................................................................................20

Back up the module...................................................................................................................................................................................................................................................20

Prepare the module for the upgrade or reinstallation........................................................................................................................................................................................20

Upgrade or reinstall the firmware of your Historian module............................................................................................................................................................................. 21

(Optional) Download ControlFLASH or ControlFLASH Plus......................................................................................................................................................................... 21

(Optional) Install ControlFLASH or ControlFLASH Plus................................................................................................................................................................................21

Download the module firmware kit..............................................................................................................................................................................................................22

Upgrade or reinstall the module firmware..................................................................................................................................................................................................22

Updates and application notes................................................................................................................................................................................................................................23

Set up your ControlLogix environment.............................................................................................................................................................................................................................24

Install the module in the chassis...................................................................................................................................................................................................................................... 24

Install FactoryTalk Historian ME Client Tools...................................................................................................................................................................................................................25

Install FactoryTalk Historian ME Management......................................................................................................................................................................................................25

Install FactoryTalk Historian ME Rule Editor......................................................................................................................................................................................................... 27

Install FactoryTalk Historian ME Logix Designer Module Profile........................................................................................................................................................................27

(Optional) Install FactoryTalk Historian SE patch.................................................................................................................................................................................................28

EDS files....................................................................................................................................................................................................................................................................... 28

Rockwell Automation, Inc. 1756-UM106H-EN-E - June 2024 3

Access the FactoryTalk Historian ME webpage...............................................................................................................................................................................................................28

Log on to FactoryTalk Historian ME........................................................................................................................................................................................................................28

Log out of FactoryTalk Historian ME...................................................................................................................................................................................................................... 29

View the module information................................................................................................................................................................................................................30

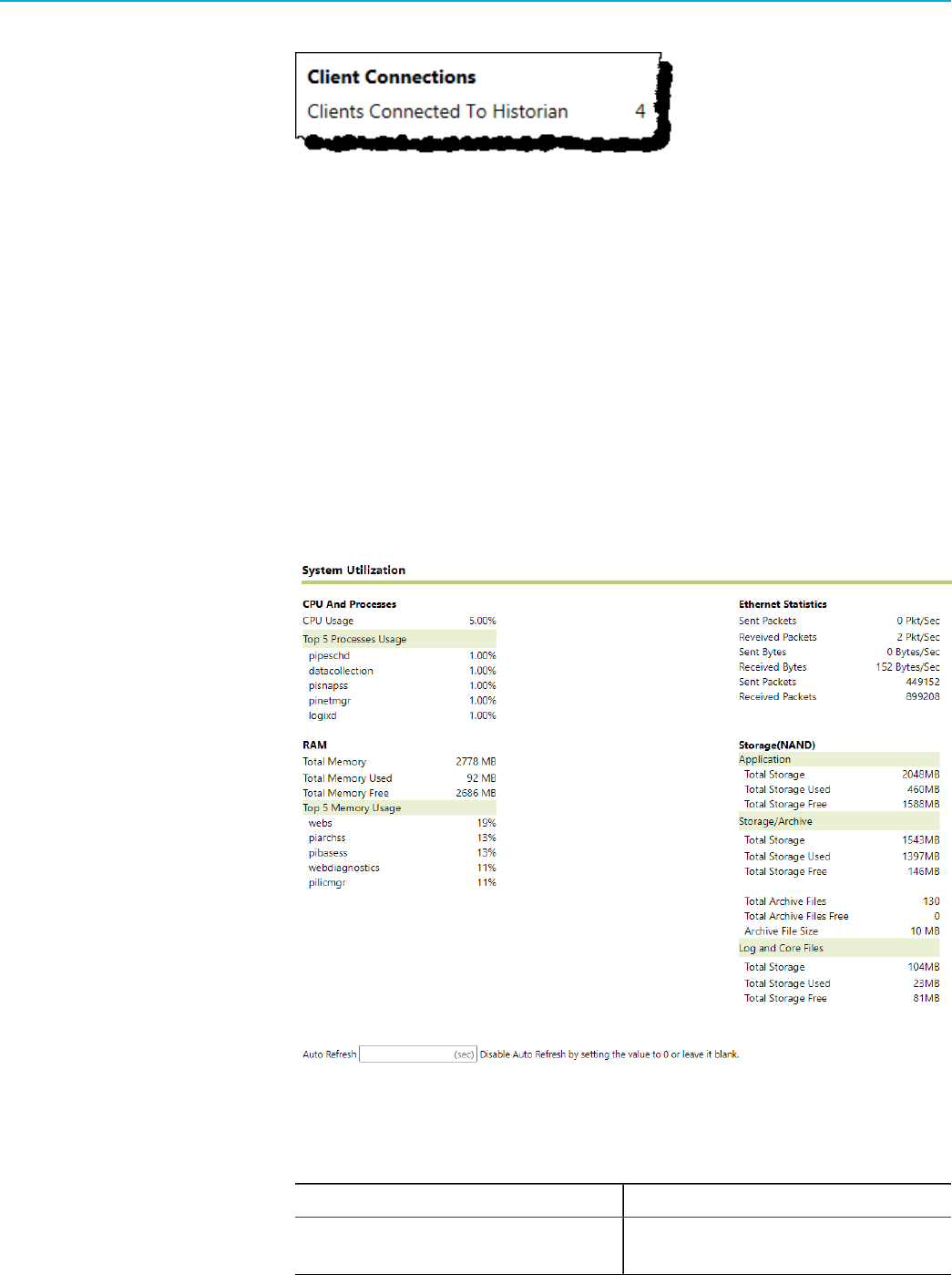

System status........................................................................................................................................................................................................................................................................30

Status....................................................................................................................................................................................................................................................................................... 31

Module information..................................................................................................................................................................................................................................................... 31

System status...............................................................................................................................................................................................................................................................31

System utilization.......................................................................................................................................................................................................................................................32

Point statistics............................................................................................................................................................................................................................................................32

Module identity...................................................................................................................................................................................................................................................................... 33

Module information.................................................................................................................................................................................................................................................... 33

Network settings.........................................................................................................................................................................................................................................................34

Security configuration...............................................................................................................................................................................................................................................34

Client connections......................................................................................................................................................................................................................................................35

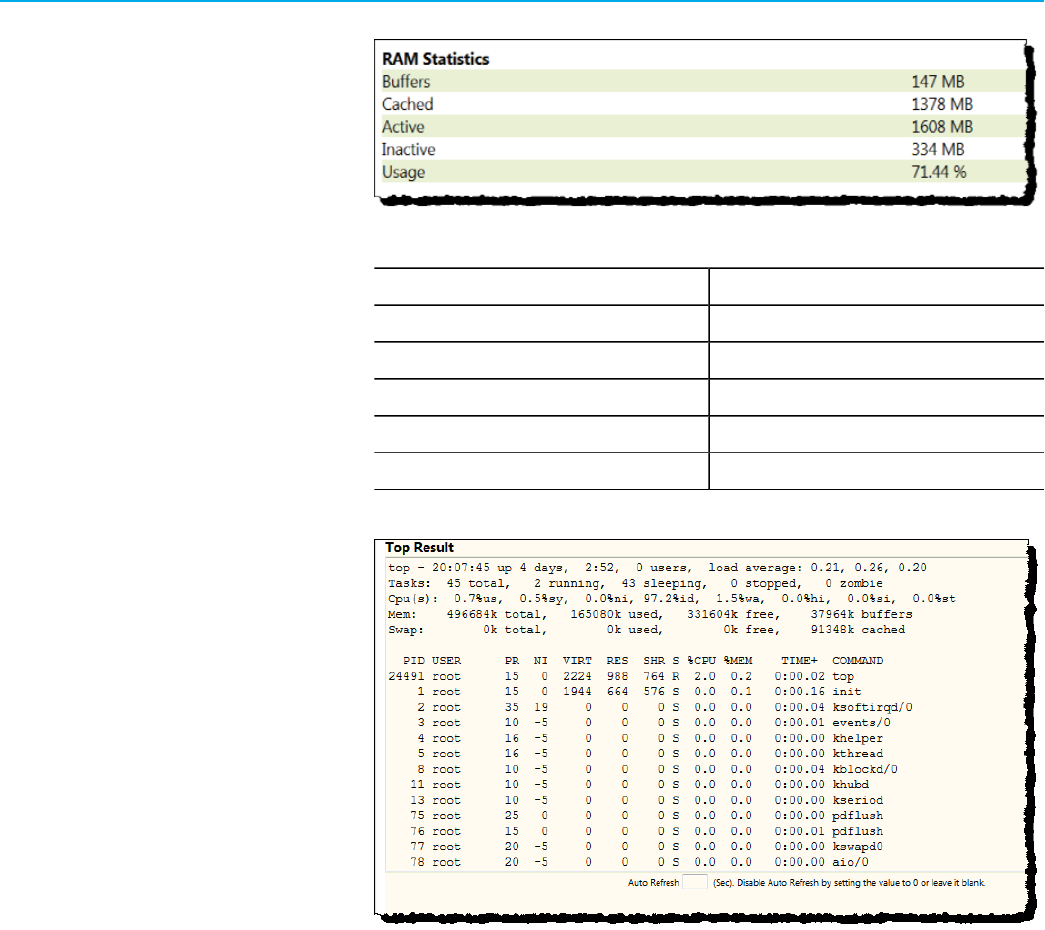

System utilization..................................................................................................................................................................................................................................................................35

System statistics...................................................................................................................................................................................................................................................................36

Network manager....................................................................................................................................................................................................................................................... 37

Snapshot and archive................................................................................................................................................................................................................................................38

Snapshot and archive counters....................................................................................................................................................................................................................38

Archive files.......................................................................................................................................................................................................................................................42

View data............................................................................................................................................................................................................................................... 45

Define search criteria.......................................................................................................................................................................................................................................................... 45

Export data.............................................................................................................................................................................................................................................................................47

View current data..................................................................................................................................................................................................................................................................47

View archive data................................................................................................................................................................................................................................................................. 47

View trends............................................................................................................................................................................................................................................................................ 48

Display points on the trend......................................................................................................................................................................................................................................49

Display the vertical bar on the trend.....................................................................................................................................................................................................................49

Zoomthetrend............................................................................................................................................................................................................................................................50

Reset the trend............................................................................................................................................................................................................................................................51

Remove points from the trend................................................................................................................................................................................................................................. 51

Change views..........................................................................................................................................................................................................................................................................51

Filter search results data......................................................................................................................................................................................................................................... 52

Arrange columns.........................................................................................................................................................................................................................................................52

4 1756-UM106H-EN-E - June 2024 Rockwell Automation, Inc.

Refresh views..............................................................................................................................................................................................................................................................52

Set start and end times............................................................................................................................................................................................................................................53

Bad quality data....................................................................................................................................................................................................................................................................53

Manage points........................................................................................................................................................................................................................................54

Recommendations related to managing points..............................................................................................................................................................................................................54

Add points using the Add Points Wizard page................................................................................................................................................................................................................54

Discover tags...............................................................................................................................................................................................................................................................54

Create points...............................................................................................................................................................................................................................................................56

Review results............................................................................................................................................................................................................................................................. 57

Add points using the Add Individual Points page...........................................................................................................................................................................................................58

Manage individual points using the Edit Points page....................................................................................................................................................................................................59

Create points...............................................................................................................................................................................................................................................................59

Edit points....................................................................................................................................................................................................................................................................60

Rename points............................................................................................................................................................................................................................................................ 60

Delete points............................................................................................................................................................................................................................................................... 60

Define point attributes......................................................................................................................................................................................................................................................... 61

General...........................................................................................................................................................................................................................................................................61

Exception filtering......................................................................................................................................................................................................................................................64

Compression filtering.................................................................................................................................................................................................................................................64

Snapshot value............................................................................................................................................................................................................................................................65

Configure scan types........................................................................................................................................................................................................................................................... 66

Configure Trigger Input and Output points......................................................................................................................................................................................................................67

Configure Trigger Input points.................................................................................................................................................................................................................................67

Configuration example: Trigger Input points..............................................................................................................................................................................................69

Configure Output points............................................................................................................................................................................................................................................70

Configuration example: Output points..........................................................................................................................................................................................................71

Manage shortcuts..................................................................................................................................................................................................................................................................72

Create shortcuts to the local chassis.....................................................................................................................................................................................................................72

Create shortcuts to a remote controller................................................................................................................................................................................................................73

Edit shortcuts..............................................................................................................................................................................................................................................................74

Delete shortcuts..........................................................................................................................................................................................................................................................75

Tag naming conventions...........................................................................................................................................................................................................................................75

Use scan classes...................................................................................................................................................................................................................................................................75

Create scan classes................................................................................................................................................................................................................................................... 76

Edit scan classes........................................................................................................................................................................................................................................................76

Rockwell Automation, Inc. 1756-UM106H-EN-E - June 2024 5

Delete scan classes....................................................................................................................................................................................................................................................76

Collect and store data........................................................................................................................................................................................................................... 77

Collect data.............................................................................................................................................................................................................................................................................77

Access the data collection information..................................................................................................................................................................................................................77

Start and stop the data collection..........................................................................................................................................................................................................................78

View the data storage information................................................................................................................................................................................................................................... 78

FactoryTalk Historian ME storage capacity...........................................................................................................................................................................................................80

Filter data................................................................................................................................................................................................................................................................................81

Exception filtering......................................................................................................................................................................................................................................................83

Compression filtering.................................................................................................................................................................................................................................................85

Transfer data to FactoryTalk Historian SE or PI servers.....................................................................................................................................................................88

Data transfer prerequisites................................................................................................................................................................................................................................................ 88

Configure the data transfer................................................................................................................................................................................................................................................89

Start the data transfer........................................................................................................................................................................................................................................................ 90

Stop the data transfer.........................................................................................................................................................................................................................................................90

View data transfer statistics..............................................................................................................................................................................................................................................90

Add points to the data transfer..........................................................................................................................................................................................................................................91

Remove points from data transfer.....................................................................................................................................................................................................................................91

View the data transfer information...................................................................................................................................................................................................................................92

Check the data transfer status in the system log......................................................................................................................................................................................................... 93

Data transfer considerations..............................................................................................................................................................................................................................................93

Administer the module.......................................................................................................................................................................................................................... 95

Manage users.........................................................................................................................................................................................................................................................................95

Create users................................................................................................................................................................................................................................................................ 95

Modify users................................................................................................................................................................................................................................................................ 96

Remove users..............................................................................................................................................................................................................................................................96

Change user passwords............................................................................................................................................................................................................................................ 96

Reset passwords......................................................................................................................................................................................................................................................... 97

Reset the default admin password......................................................................................................................................................................................................................... 97

View groups............................................................................................................................................................................................................................................................................97

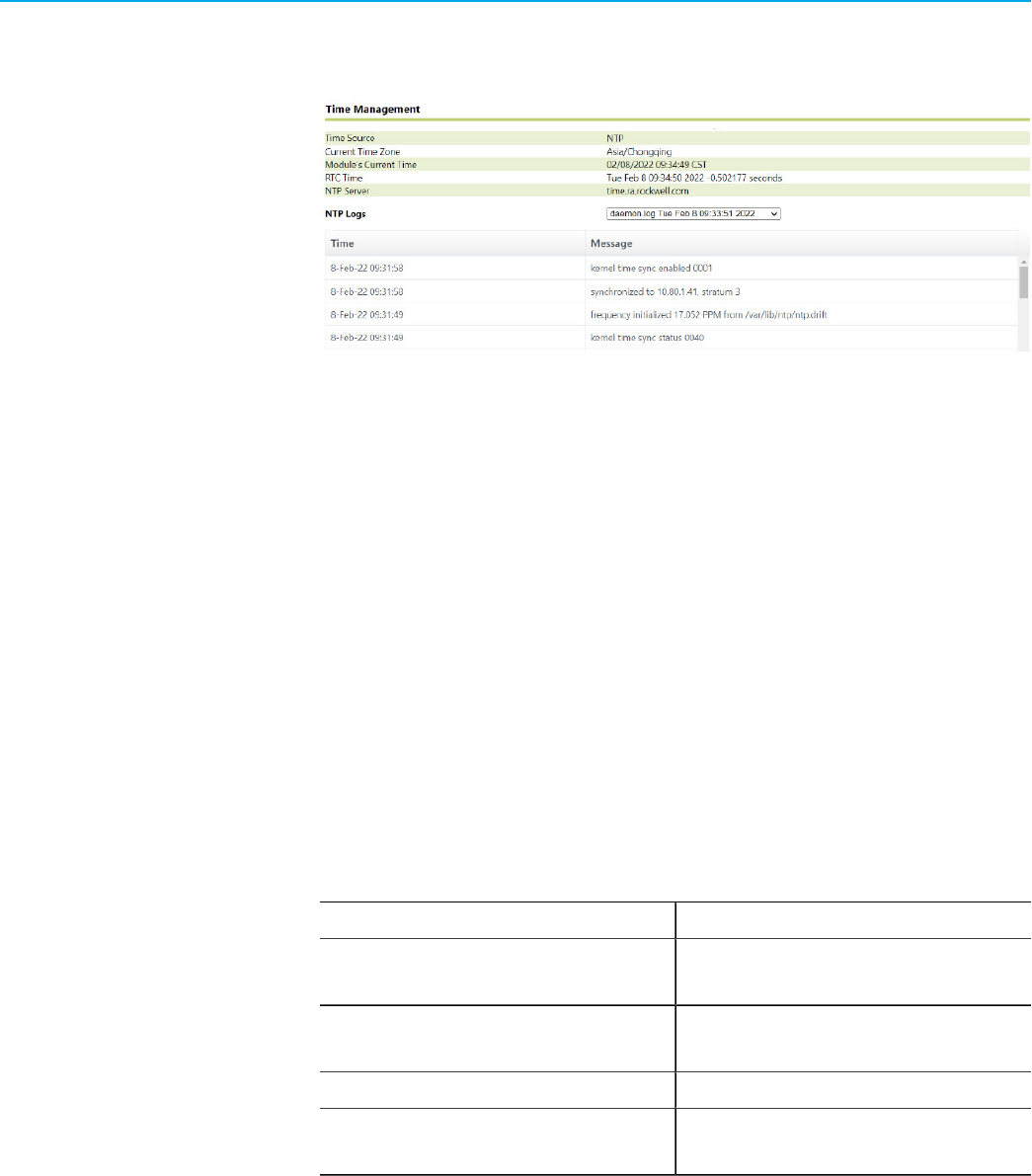

Manage time...........................................................................................................................................................................................................................................................................98

View and edit the current time............................................................................................................................................................................................................................... 99

Considerations for using an NTP server as the time source................................................................................................................................................................ 100

Verify time synchronization.....................................................................................................................................................................................................................................101

Set the time zone...................................................................................................................................................................................................................................................... 101

6 1756-UM106H-EN-E - June 2024 Rockwell Automation, Inc.

Clock drifts.................................................................................................................................................................................................................................................................102

Battery clock..............................................................................................................................................................................................................................................................102

Configure system settings.................................................................................................................................................................................................................................................102

Change the module name....................................................................................................................................................................................................................................... 102

Configure network settings.....................................................................................................................................................................................................................................103

Upload files to the module................................................................................................................................................................................................................................................105

File types.................................................................................................................................................................................................................................................................... 106

Manage the uploaded files...................................................................................................................................................................................................................................... 107

Back up and restore configuration files.........................................................................................................................................................................................................................107

View the backup status and perform backup.....................................................................................................................................................................................................108

Download the backup file to a client computer................................................................................................................................................................................................. 108

Upload the backup file to the module..................................................................................................................................................................................................................109

Restore the module from the backup file............................................................................................................................................................................................................109

Why restoring PI Server ID?..........................................................................................................................................................................................................................110

Check and restore the module name.....................................................................................................................................................................................................................111

Use the system log............................................................................................................................................................................................................................................................... 111

System log related issues........................................................................................................................................................................................................................................ 112

Repair archives using safe mode..................................................................................................................................................................................................................................... 112

Repair the time setting.............................................................................................................................................................................................................................................113

Restore and reset module-related settings.....................................................................................................................................................................................................................113

Restore the module's defaults.................................................................................................................................................................................................................................114

Reset the security mode.......................................................................................................................................................................................................................................... 114

Reset the Web Diagnostics password....................................................................................................................................................................................................................115

Close and start the module................................................................................................................................................................................................................................................115

Shut down the module..............................................................................................................................................................................................................................................115

Reboot the module.................................................................................................................................................................................................................................................... 116

Restart the module....................................................................................................................................................................................................................................................116

Manage security.................................................................................................................................................................................................................................... 117

Configure security................................................................................................................................................................................................................................................................ 117

Configure system timeout........................................................................................................................................................................................................................................ 117

Configure how to log on to the module.................................................................................................................................................................................................................117

Log on using the FactoryTalk Directory with FactoryTalk Historian ME...............................................................................................................................................118

Understand privileges for user groups....................................................................................................................................................................................................... 119

Configure where to use the secure communication protocol (HTTPS)............................................................................................................................................................121

Manage security trusts.......................................................................................................................................................................................................................................................123

Rockwell Automation, Inc. 1756-UM106H-EN-E - June 2024 7

Default trusts............................................................................................................................................................................................................................................................. 124

User-defined trusts...................................................................................................................................................................................................................................................124

Create trusts for the data transfer.............................................................................................................................................................................................................124

Create trusts for FactoryTalk Historian clients........................................................................................................................................................................................ 125

Edit trusts...................................................................................................................................................................................................................................................................126

Delete trusts...............................................................................................................................................................................................................................................................126

Integrate the module into a FactoryTalk environment with FactoryTalk Directory................................................................................................................................................ 126

Integration prerequisites.........................................................................................................................................................................................................................................126

Register the module in the FactoryTalk Directory..............................................................................................................................................................................................127

Add the Historian ME module in the PI SDK Utility...................................................................................................................................................................................127

Register the Historian ME module in the FactoryTalk Administration Console...................................................................................................................................127

Create users in the FactoryTalk Administration Console..................................................................................................................................................................................128

Configure secure groups in the FactoryTalk Administration Console.............................................................................................................................................................129

SNMP community strings................................................................................................................................................................................................................................................... 129

Enable SNMP...............................................................................................................................................................................................................................................................129

Create SNMP community strings............................................................................................................................................................................................................................130

Delete SNMP community strings............................................................................................................................................................................................................................130

Use the Rule Editor............................................................................................................................................................................................................................... 131

View the default point discovery rule file.......................................................................................................................................................................................................................131

Create point discovery rule files.......................................................................................................................................................................................................................................131

Define point discovery rules..............................................................................................................................................................................................................................................132

Change the point discovery limit...........................................................................................................................................................................................................................134

Edit point discovery rule files...........................................................................................................................................................................................................................................134

Remove point discovery rule files....................................................................................................................................................................................................................................134

Create tag attribute files................................................................................................................................................................................................................................................... 135

Edit tag attribute files........................................................................................................................................................................................................................................................ 139

Remove tag attribute files.................................................................................................................................................................................................................................................139

Use Studio 5000 Logix Designer Module Profile................................................................................................................................................................................. 140

Configure your Historian module in the Module Profile...............................................................................................................................................................................................140

Configure the module properties..................................................................................................................................................................................................................................... 140

Example: Use the Module Profile......................................................................................................................................................................................................................................142

Add an Ethernet driver.............................................................................................................................................................................................................................................142

Add the module to Studio 5000 Logix Designer................................................................................................................................................................................................. 143

Use output tags to start and stop the data collection......................................................................................................................................................................................144

Use the input and output tags to read the Historian ME status................................................................................................................................................................................145

8 1756-UM106H-EN-E - June 2024 Rockwell Automation, Inc.

Create trends with the FactoryTalk Historian DataLink Add-in..........................................................................................................................................................148

Define the server connection............................................................................................................................................................................................................................................148

Insert trends in a Microsoft Excel workbook.................................................................................................................................................................................................................149

Create trends visualizing the data transfer...................................................................................................................................................................................................................150

Use Web Diagnostics............................................................................................................................................................................................................................ 152

Home...................................................................................................................................................................................................................................................................................... 153

Hardware............................................................................................................................................................................................................................................................................... 153

Overview......................................................................................................................................................................................................................................................................154

CPU, RAM..................................................................................................................................................................................................................................................................... 154

NAND............................................................................................................................................................................................................................................................................ 155

Controller statistics...................................................................................................................................................................................................................................................157

ControlBus statistics.................................................................................................................................................................................................................................................158

EtherNet/IP.................................................................................................................................................................................................................................................................159

Display LED.................................................................................................................................................................................................................................................................160

Time management.....................................................................................................................................................................................................................................................161

Firmware................................................................................................................................................................................................................................................................................162

Overview......................................................................................................................................................................................................................................................................162

Historian server.........................................................................................................................................................................................................................................................162

CIP................................................................................................................................................................................................................................................................................ 163

Data server.................................................................................................................................................................................................................................................................163

Data collection...........................................................................................................................................................................................................................................................164

Data transfer..............................................................................................................................................................................................................................................................165

Data storage...............................................................................................................................................................................................................................................................165

Web configuration server........................................................................................................................................................................................................................................ 167

Web diagnostics server............................................................................................................................................................................................................................................167

Startup log..................................................................................................................................................................................................................................................................168

Admin..................................................................................................................................................................................................................................................................................... 168

Hosts............................................................................................................................................................................................................................................................................169

Restart service...........................................................................................................................................................................................................................................................169

Core dump directory.................................................................................................................................................................................................................................................169

PI commands............................................................................................................................................................................................................................................................. 170

Download logs............................................................................................................................................................................................................................................................170

Change password......................................................................................................................................................................................................................................................170

Troubleshoot......................................................................................................................................................................................................................................... 172

Provide issue information.................................................................................................................................................................................................................................................. 172

Rockwell Automation, Inc. 1756-UM106H-EN-E - June 2024 9

Reboot the module.............................................................................................................................................................................................................................................................. 173

Work in the safe mode.......................................................................................................................................................................................................................................................173

Hardware issues...................................................................................................................................................................................................................................................................173

Web client issues.................................................................................................................................................................................................................................................................174

Data collection issues.........................................................................................................................................................................................................................................................175

Data storage issues.............................................................................................................................................................................................................................................................177

Data transfer issues............................................................................................................................................................................................................................................................177

Data export issues...............................................................................................................................................................................................................................................................179

Auto recovery issues...........................................................................................................................................................................................................................................................179

Time management issues..................................................................................................................................................................................................................................................180

Client computer issues.......................................................................................................................................................................................................................................................180

Point server issues.............................................................................................................................................................................................................................................................. 181

Related FactoryTalk product issues..................................................................................................................................................................................................................................181

FactoryTalk Directory................................................................................................................................................................................................................................................181

FactoryTalk Historian DataLink............................................................................................................................................................................................................................... 181

Configure Internet Explorer for FactoryTalk Historian ME..................................................................................................................................................................182

Internet Explorer configuration checklist.......................................................................................................................................................................................................................182

Add the module site to Local intranet or Trusted sites...............................................................................................................................................................................................182

Add the module website to the Local intranet security zone.......................................................................................................................................................................... 183

Add the module website to the Trusted sites security zone............................................................................................................................................................................184

Enable Active X controls.................................................................................................................................................................................................................................................... 184

Enable Compatibility View..................................................................................................................................................................................................................................................185

Disable Pop-up Blocker......................................................................................................................................................................................................................................................185

Disable ActiveX Filtering.....................................................................................................................................................................................................................................................185

Enable the XML DOM Document add-on..........................................................................................................................................................................................................................186

Enable TLS.............................................................................................................................................................................................................................................................................186

Verify the browser configuration using the F12 developer tools................................................................................................................................................................................187

Install the module certificate in Internet Explorer........................................................................................................................................................................................................187

Install the certificate using the Certificate Import Wizard...............................................................................................................................................................................188

Verify the certificate...........................................................................................................................................................................................................................................................188

Verify the certificate on the security report.......................................................................................................................................................................................................188

Verify the certificate on the System Security page...........................................................................................................................................................................................189

Clear the browser cache....................................................................................................................................................................................................................................................189

Clear the browser cache manually........................................................................................................................................................................................................................189

Clear the browser cache automatically................................................................................................................................................................................................................190

10 1756-UM106H-EN-E - June 2024 Rockwell Automation, Inc.

Add a registry entry for exporting files to Excel.......................................................................................................................................................................................................... 190

Configure Internet Explorer on Windows Server...........................................................................................................................................................................................................190

Internet Explorer security zone settings......................................................................................................................................................................................................................... 191

Rockwell Automation, Inc. 1756-UM106H-EN-E - June 2024 11

Preface

About This Publication

Rockwell Automation recognizes that some of the terms that are currently used in our industry and in this publication are not in alignment with the movement toward

inclusive language in technology. We are proactively collaborating with industry peers to find alternatives to such terms and making changes to our products and content.