Table Of Contents

UL Listings

C-AJ-1664 (Canada Only).................................................................................................................... 1

C-AJ-4106 (Canada Only).................................................................................................................... 2

C-AJ-8248 (Canada Only).................................................................................................................... 3

C-BJ-1069 (Canada Only).................................................................................................................... 9

W-J-0024 (Canada Only)....................................................................................................................11

W-J-4078 (Canada Only)....................................................................................................................12

W-L-0048 (Canada Only)....................................................................................................................13

W-L-1518 (Canada Only)....................................................................................................................14

W-L-1519 (Canada Only)....................................................................................................................15

W-L-8104 (Canada Only)....................................................................................................................16

CFS-BL

Product Data Sheet for CFS-BL Firestop Block..................................................................................21

UL Certificate of Compliance for CFS-BL Firestop Block................................................................... 22

LEED Information for CFS-BL Firestop Block.....................................................................................23

CP 648-E (Endless)

Product Data Sheet for CP 648-E Firestop Wrap Strip.......................................................................24

UL Certificate of Compliance for CP 648-E and CP 648-S Firestop Wrap Strip.................................25

LEED Information for CP 648-S and CP 648-E Firestop Wrap Strip.................................................. 26

CP 660

UL Certificate of Compliance for CP 660 Firestop Foam....................................................................27

Hilti Firestop Systems

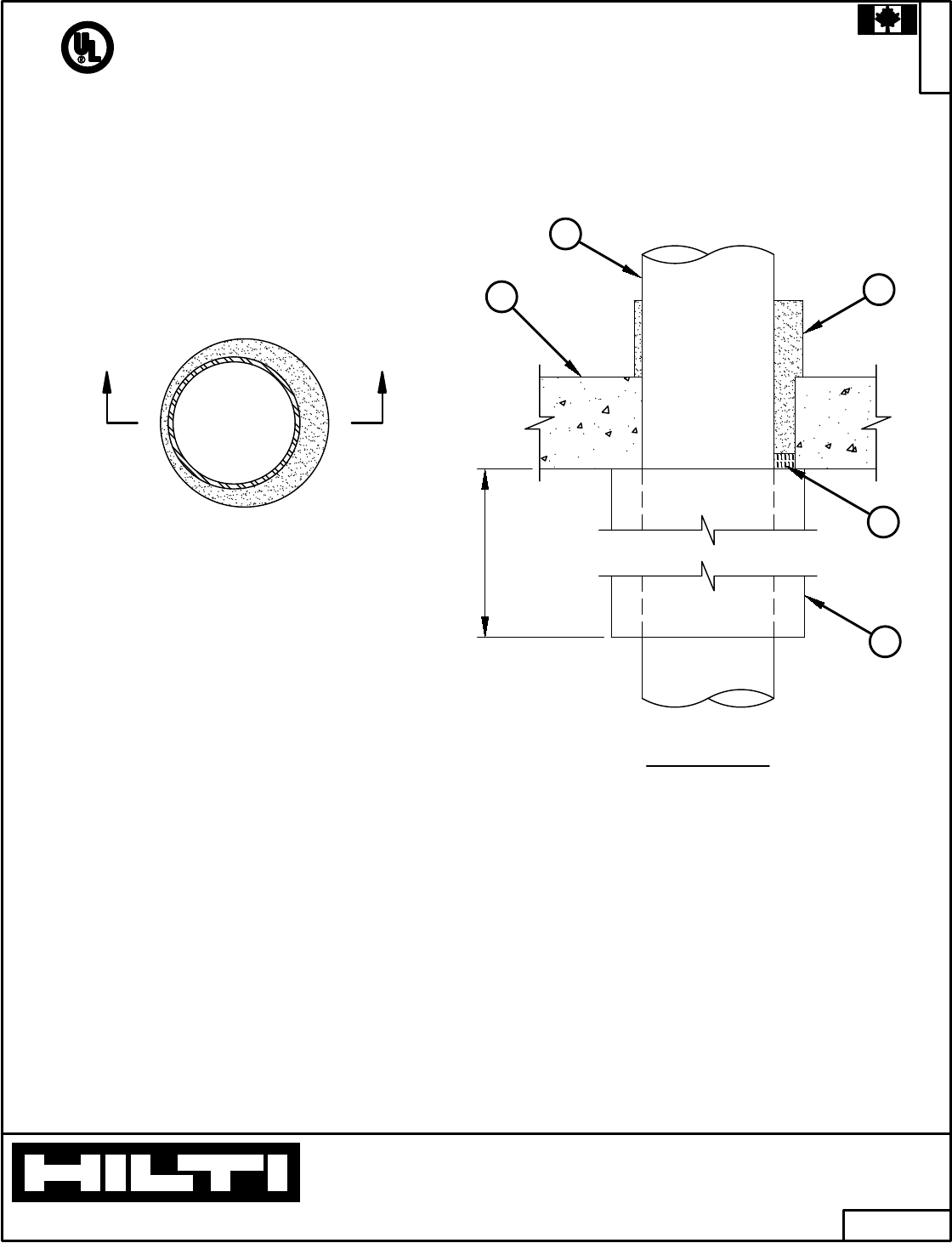

System No. C-AJ-4106

SECTION A-A

CAJ 4106

1. Floor or Wall Assembly — Min 114 mm (4-1/2 in.) thick reinforced lightweight or normal weight (1600-2400 kg/m3 or 100-150 pcf) concrete. Wall

may also be constructed of any UL Classified Concrete Blocks*. Max area of opening is (1445 cm2 or 224 in2) with max dimension of 813 mm (32

in.).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2. Cable Tray* — Max 610 mm (24 in.) wide by 102 mm (4 in.) deep open-ladder cable tray with channel-shaped side rails formed of 2.54 mm thick

aluminum and 38 mm (1-1/2 in.) wide by 25 mm (1 in.) channel shaped rungs spaced on 229 mm (9 in.) OC. The annular space between cable

tray and periphery of opening shall be min 0 mm (point contact) to max 127 mm (5 in.). Cable tray to be rigidly suported on both sides of wall

assembly.

3. Cables — Aggregate cross-sectional area of cable tray to be max 45 percent of the cross-sectional area of the cable tray. Any combination of the

following types and sizes of copper conductor cables may be used:

A. Max 300 pair No. 24 AWG telephone cable with polyvinyl chloride (PVC) insulation and jacket.

B. Max 500 kcmil single conductor copper power cable with PVC jacket material.

C. Multiple fiber optical communication cable jacketed with PVC and having a max OD of 9.5 mm (3/8 in.)

D. Max 3/C No. 12 AWG copper conductor steel clad cable with PVC insulation material.

4. Firestop System — The firestop system shall consist of the following:

A. Fill, Void or Cavity Materials* — Foam — Min 127 mm (5 in.) thickness of fill material applied within the annulus, extending 13 mm (1/2 in.)

above the top surface of the floor or both surfaces of wall and overlapping the concrete 13 mm (1/2 in.) on all sides of the opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

B. Fill, Void or Cavity Materials — (Optional — Not Shown) — Nom 51 mm (2 in.) deep Fire Blocks applied in a single layer above cables within

cable tray with 127 mm (5 in.) dimension projecting through the opening and long dimension parallel to floor or wall. Either one or a

combination of the block types specified below may be used.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — FS 657 Fire Block or CFS-BL Firestop Block

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

A

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

F Rating - 2 Hr

T Rating - 0 Hr

FH Rating - 0 Hr

FTH Rating - 0 Hr

A

CANADA ONLY

C

C

L

A

S

S

I

F

I

E

D

Classified by

Underwriters Laboratories, Inc.

to CAN/ULC-S115

4

3

2

1

4

Hilti Firestop Systems

System No. C-AJ-8248

CAJ8248

Page: 1 of 6

D

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

F Rating - 2 Hr

FT Rating - 0, 1/2 and 2 Hr (See Item 2)

FH Rating - 0 Hr

FTH Rating - 0 Hr

D

EE

FF

CC

AA

GG

BB

CANADA ONLY

C

C

L

A

S

S

I

F

I

E

D

Classified by

Underwriters Laboratories, Inc.

to CAN/ULC-S115

Page: 2 of 6

Hilti Firestop Systems

SECTION A-A

System No. C-AJ-8248

CAJ8248

SECTION B-B

SECTION C-C SECTION D-D

2

3

2

4B

4A

3

1

2

3A

3B

3

2

3

1

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

FIRESTOP CONFIGURATION A FIRESTOP CONFIGURATION B

FIRESTOP CONFIGURATION DFIRESTOP CONFIGURATION C

CANADA ONLY

Page: 3 of 6

Hilti Firestop Systems

System No. C-AJ-8248

CAJ8248

SECTION E-E SECTION F-F

SECTION G-G

3

2

4

1

3

2

3

2

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

FIRESTOP CONFIGURATION FFIRESTOP CONFIGURATION E

FIRESTOP CONFIGURATION G

CANADA ONLY

Page: 4 of 6

1. Floor or Wall Assembly — Min 114 mm (4-1/2 in.) thick reinforced lightweight or normal weight (1600-2400 kg/m3 or 100-150 pcf) concrete.

Wall may also be constructed of any UL Classified Concrete Blocks*. Max area of 3871 cm2 (600 in2) with max dimension of 762 mm (30 in.).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2. Through Penetrants — A max of seven firestop configurations may be installed within the opening. The space between firestop configurations

shall be as specified in the individual configurations. Unless otherwise indicated, the space between firestop configurations and periphery of

opening shall be min 13 mm (1/2 in.) to max 140 mm (5-1/2 in.). Pipe, conduit, tubing or cables to be rigidly supported on both sides of floor or

wall assembly. The T Rating of the system is dependent on the firestop configurations, as shown in the table below. Any combination of the

following firestop configurations detailed herein may be used:

Firestop Configuration A

2. Cables — Max 102 mm (4 in.) diam of tightly bundled cables. The min annular space between adjacent penetrants shall be 102 mm (4 in.).

Cable bundle may be any combination of the following types and sizes of cables:

A. Max 300 pair No. 24 AWG copper telephone cables with polyvinyl chloride (PVC) insulation and jacket materials.

B. Max 500 kcmil single conductor copper power cable with PVC jacket material.

C. Max 7/C No. 12 AWG cable with polyvinyl PVC insulation and jacket materials.

D. Multiple fiber optical communication cables with PVC jacket material and having a max outside diameter of 3/8 in.

E. Max 3/C No. 12 AWG steel clad cables with PVC insulation materials.

F. Max 3/C No. 10 AWG cables with ground with PVC insulation and jacket materials.

3. Fill, Void or Cavity Materials* — Foam — Min 127 mm (5 in.) thickness of fill material applied within the annulus, extending 13 mm (1/2 in.)

above the top surface of the floor or both surfaces of wall and overlapping the concrete 13 mm (1/2 in.) on all sides of the opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

Firestop Configuration B

2. Copper Tube or Pipe — Nom 51 mm (2 in.) diam (or smaller) Type L copper tube or nom 51 mm (2 in) diam (or smaller) Regular (or heavier)

copper pipe. Min space between adjacent penetrants shall be 76 mm (3 in.).

3. Tube Insulation-Plastics+ — Nom 19 mm (3/4 in.) thick acrylonitrile butadiene/polyvinyl chloride (AB/PVC) flexible foam furnished in the form

of tubing. The min space between adjacent penetrants shall be 76 mm (3 in.). See Plastics+ (QMFZ2) category in the Plastics Recognized

Component Directory for names of manufacturers. Any Recognized Component tube insulation material meeting the above specifications and

having a UL 94 Flammability Classification of 94-5VA may be used.

4. Firestop System — The firestop system shall consist of the following:

A. Fill, Void or Cavity Material* — Wrap Strip — Min 25 mm (1 in.) wide wrap strip applied in a single wrap installed flush with bottom surface

of floor or extending 1/2 in. beyond both surfaces of wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 648E Wrap Strip

B. Fill, Void or Cavity Materials* — Foam — Min 127 mm (5 in.) thickness of fill material applied within the annulus, extending 13 mm (1/2

in.) above the top surface of the floor or both surfaces of wall and overlapping the concrete 1/2 in. on all sides of the opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

Hilti Firestop Systems

System No. C-AJ-8248

CAJ8248

Firestop Configuration

T Rating Hr

A 1/2

B 1/2

C

0

D

0

E 2

F 1/2

G

0

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

CANADA ONLY

Page: 5 of 6

Hilti Firestop Systems

Firestop Configuration C

2. Polyvinyl Chloride (PVC) Pipe — Nom 102 mm (4 in.) diam (or smaller) Schedule 40 solid or cellular core PVC pipe for used in closed

(process or supply) or vented (drain, waste or vent) piping systems. The min space between adjacent penetrants shall be 114 mm (4-1/2 in.).

3. Firestop System — The firestop system shall consist of the following:

A. Fill, Void or Cavity Material* — Wrap Strip — Two stacks of min 44 mm (1-3/4 in.) wide wrap strips, each applied in a single wrap and

tightly butted, installed flush with bottom surface of floor or both surfaces of wall or extending 13 mm (1/2 in.) beyond both surfaces of wall.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 648E Wrap Strip

B. Fill, Void or Cavity Materials* — Foam — Min 127 mm (5 in.) thickness of fill material applied within the annulus flush with bottom surface

and extending 13 mm (1/2 in.) above the top surface of the floor or extending 13 mm (1/2 in.) beyond both surfaces of wall and

overlapping the concrete 13 mm (1/2 in.) on all sides of the opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

Firestop Configuration D

2. Through Penetrant — One metallic pipe, conduit or tube to be installed either concentrically or eccentrically within the firestop system. The

min annular space between the pipe, conduit of tube and periphery of opening shall be 0 mm (point contact). The min space between adjacent

penetrants shall be 102 mm (4 in.). Pipe, conduit of tube to be rigidly supported on both sides of floor or wall assembly. The following types

and sizes of metallic pipes, conduits or tubes may be used:

A. Nom 102 mm (4 in.) diam (or smaller) Schedule 10 (or heavier) steel pipe.

B. Nom 102 mm (4 in.) diam (or smaller) cast or ductile iron pipe.

C. Nom 102 mm (4 in.) diam (or smaller) rigid steel conduit.

D. Nom 102 mm (4 in.) diam (or smaller) steel electrical metallic conduit.

E. Nom 102 mm (4 in.) diam (or smaller) Type L (or heavier) copper tubing.

F. Nom 102 mm (4 in.) diam (or smaller) Regular (or heavier) copper pipe.

3. Fill, Void or Cavity Material* — Foam — Min 127 mm (5 in.) thickness of fill material applied within the annulus, extending 13 mm (1/2 in.)

above the top surface of the floor or both surfaces of wall and overlapping the concrete 13 mm (1/2 in.) on all sides of the opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

Firestop Configuration E

2. Steel Pipe — Nom 203 mm (8 in.) diam (or smaller) Schedule 40 (or heavier) steel pipe.

3. Pipe Covering Materials* — Nom 38 mm (1-1/2 in.) thick hollow cylindrical heavy density (min 3.5 pcf) glass fiber units jacketed on the outside

with an all-service jacket. Longitudinal joints sealed with metal fasteners or factory-applied, self-sealing lap tape. Transverse joints secured

with metal fasteners of with butt tape supplied with product. The min space between adjacent penetrants shall be 76 mm (3 in.).

See Pipe and Equipment Covering - Materials (BRGU) Category in the Building Materials Directory for names of manufacturers. Any pipe

covering meeting the above specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a

Smoke Developed Index of 50 or less may be used.

4. Fill, Void or Cavity Materials* — Foam — Min 127 mm (5 in.) thickness of fill material applied within the annulus, extending 13 mm (1/2 in.)

above the top surface of the floor or both surfaces of wall and overlapping the concrete 13 mm (1/2 in.) on all sides of the opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

Firestop Configuration F

2. Cable — Nom 51 mm (2 in.) diam (or smaller) TEK cable with cross-linked polyethylene insulation. The min space between adjacent

penetrants shall be 76 mm (3 in.).

3. Fill, Void or Cavity Material* — Foam — Min 127 mm (5 in.) thickness of fill material applied within the annulus, extending 13 mm (1/2 in.)

above the top surface of the floor or both surfaces of wall and overlapping the concrete 13 mm (1/2 in.) on all sides of the opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

System No. C-AJ-8248

CAJ8248

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

CANADA ONLY

Hilti Firestop Systems

Page: 6 of 6

Firestop Configuration G

2. Flexible Conduit — Nom 25 mm (1 in.) diam (or smaller) flexible aluminum conduit. The min space between adjacent penetrants shall be 127

mm (5 in.).

3. Fill, Void or Cavity Material* — Foam — Min 127 mm (5 in.) thickness of fill material applied within the annulus, extending 13 mm (1/2 in.)

above the top surface of the floor or both surfaces of wall and overlapping the concrete 13 mm (1/2 in.) on all sides of the opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

+ Bearing the UL Listing Mark

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

System No. C-AJ-8248

CAJ8248

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

CANADA ONLY

Hilti Firestop Systems

System No. C-BJ-1069

SECTION A-A

CBJ1069

Page: 1 of 2

1. Floor or Wall Assembly — Min 152 mm (6 in.) thick reinforced lightweight or normal weight (1600-2400 kg/m3 or 100-150 pcf) concrete. Wall may

also be constructed of any solid or filled UL Concrete Blocks*. Max diameter of opening is 254 mm (10 in.).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2. Through Penetrants — One metallic pipe to be installed either concentrically or eccentrically within the firestop system. The annular space shall

be min 0 mm (point contact) to max 35 mm (1-3/8 in.). Pipe to be rigidly supported on both sides of the floor or wall assembly. The following types

and sizes of metallic pipes may be used:

A. Steel Pipe — Nom 203 mm (8 in.) diam (or smaller) Schedule 40 (or heavier) steel pipe.

B. Iron Pipe — Nom 203 mm (8 in.) diam (or smaller) cast or ductile iron pipe.

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

F Rating - 2 Hr

FT Rating - 2 Hr

FH Rating - 0 Hr

FTH Rating - 0 Hr

AA

30"

2

1

3B

3A

3C

CANADA ONLY

C

C

L

A

S

S

I

F

I

E

D

Classified by

Underwriters Laboratories, Inc.

to CAN/ULC-S115

Page: 2 of 2

3. Firestop System — The firestop system shall consist of the following:

A. Packing Material — Min 25 mm (1 in.) thickness of 64 kg/m3 (4 pcf) mineral wool batt insulation tightly packed into the opening as a

permanent form. Packing material to be recessed from top surface of floor as required to accommodate the required thickness of fill

material. Packing material not required in walls.

B. Fill, Void or Cavity Materials* — Foam — Min 127 mm (5 in.) thickness of fill material applied within the annulus, flush with top surface of

floor or min 152 mm (6 in.) thickness of fill material applied within the annulus, flush with both surfaces of wall. Additional fill material shall

extend above the top surface of the floor in accordance with the following table and shall overlap the concrete 13 mm (1/2 in.) around the

perimeter of the opening.

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

Hilti Firestop Systems

System No. C-BJ-1069

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

CBJ1069

Concrete Thickness - mm (In.)

Foam Extension Above

Surface - mm (In.)

152 (6) 102 (4)

178 (7) 76 (3)

203 (8) 51 (2)

229 (9) 25 (1)

254 (10)

None

C. Pipe Covering Materials* — Nom 51 mm (2 in.) thick unfaced mineral fiber pipe insulation sized to the outside diam of pipe or tube. Pipe

insulation shall extend 762 mm (30 in.) along length of pipe, flush with lower surfaces of floor or both surfaces of wall. Pipe insulation

secured with nom 16 AWG steel wire spaced max 152 mm (6 in.) OC.

IIG MINWOOL L L C — High Temperature Pipe Insulation 1200, High Temperature Pipe Insulation BWT or High Temperature Pipe Insulation

Thermaloc

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

CANADA ONLY

Hilti Firestop Systems

System No. W-J-0024

SECTION A-A

WJ0024

1. Wall Assembly — Min 121 mm and 152 mm (4-3/4 in. and 6 in.) thick reinforced lightweight or normal weight (1600-2400 kg/m3 or 100-150 pcf)

concrete for 1 and 2 hr fire rated walls, respectively. Wall may also be constructed of any solid or filled UL Classified Concrete Blocks*. Max area

of opening is 2903 cm2 (450 in2) with max dimension of 762 mm (30 in.).

See Concrete Blocks (CAZT) category in the Fire Resistance Directory for names of manufacturers.

2. Fill, Void or Cavity Materials* — Foam Fill material applied within annulus flush with one surface of the wall. Min fill material thickness for 1 hr F

and T Ratings is 121 mm (4-3/4 in.). Min fill material thickness for 2 hr F and T Ratings is 152 mm (6 in.).

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC — CP 660 Firestop Foam

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

A

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

F Rating - 1 and 2 Hr (See Items 1 and 2)

FT Rating - 1 and 2 Hr (See Item 2)

FH Rating - 0 Hr

FTH Rating - 0 Hr

A

1

2

CANADA ONLY

C

C

L

A

S

S

I

F

I

E

D

Classified by

Underwriters Laboratories, Inc.

to CAN/ULC-S115

System No. W-L-8104

SECTION B-B

WL 8104

Page: 1 of 5

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

F Ratings — 1 and 2 Hr (See Items 1, 3 and 4)

FT Ratings — 0, 1/2, 1, 1-1/2 and 2 Hr (See Item 2)

FH Rating — 0 Hr

FTH Rating — 0 Hr

Hilti Firestop Systems

CANADA ONLY

C

C

L

A

S

S

I

F

I

E

D

Classified by

Underwriters Laboratories, Inc.

to CAN/ULC-S115

SECTION A-A

A

A

F

C

G

C

F

G

B

B

E

E

D

D

1

2

3

2

3

4A

4B

Page: 2 of 5

Hilti Firestop Systems

System No. W-L-8104

WL 8104

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

C

C

L

A

S

S

I

F

I

E

D

Classified by

Underwriters Laboratories, Inc.

to CAN/ULC-S115

SECTION F-F

SECTION E-E

SECTION D-DSECTION C-C

2

3B

3A

1

2

3

1

2

3

4

3

2

Page: 3 of 5

Hilti Firestop Systems

System No. W-L-8104

WL 8104

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

C

C

L

A

S

S

I

F

I

E

D

Classified by

Underwriters Laboratories, Inc.

to CAN/ULC-S115

SECTION G-G

1

2

3

the individual U400, W400 or V400 Series Wall or Partition Design in the UL Fire Resistance Directory and shall include the following construction

features:

and Partition Design. Max area of opening is 2903 cm2 (450 in2) with max dimension of 762 mm (30 in.).

The hourly F Rating of the firestop system is equal to the hourly fire rating of the wall asembly in which it is installed.

Unless otherwise indicated, the space between firestop configurations and periphery of opening shall be min 9.5 mm (3/8 in.). Pipe, conduit,

tubing or cables to be rigidly supported on both sides of floor or wall assembly. The T Rating of the sytem is dependent on the firestop

configurations, as shown in the table below. Any combination of the following firestop configurations detailed herein may be used:

Firestop Configuration

1 Hr F Rating

FT Rating Hr

2 Hr F Rating

FT Rating Hr

A 0 1/2

B 1 1-1/2

C 1/2 1

D 0 0

E 1 2

F 0 0

G 0 0

Page: 4 of 5

Firestop Configuration A

be any combination of the following types and sizes of cables:

A. Max 25 pair No. 24 AWG copper telephone cable with polyvinyl chloride (PVC) insulation and jacket materials.

B. Max 7/C No. 12 AWG cable with PVC insulation and jacket materials.

C. Multiple fiber optical communication cables with PVC jacket material and having a max outside diameter of 3/8 in.

D. Max 3/C No. 12 AWG steel clad cables with PVC insulation and jacket materials.

E. Max 3/C No. 8 AWG cable with ground with PVC insulation and jacket materials.

F. Max RG 59 coaxial cables with PVC insulation and jacket materials.

F Rating is 121 mm (4-3/4 in.). Min fill material thickness for 2 hr F Rating is 152 mm (6 in.).

Firestop Configuration B

copper pipe. Min space between adjacent penetrants shall be 76 mm (3 in.).

tubing. The min space between adjacent penetrants shall be 38 mm (1-1/2 in.).

See Plastics+ (QMFZ2) category in the Plastics Recognized Component Directory for names of manufacturers. Any Recognized Component tube

insulation material meeting the above specifications and having a UL 94 Flammability Classificationof 94-5VA may be used.

continuously wrapped around the outer circumference of the pipe covering one time and held in place with tape. Wrap strips are installed flush

with each side of wall.

1 hr F Rating is 121 mm (4-3/4 in.). Min fill material thickness for 2 hr F Rating is 152 mm (6 in.).

Firestop Configuration C

supply) or vented (drain, waste or vent) piping system. The min space between non-metallic penetrants shall be 25 mm (1 in.). The min space

between metallic penetrants shall be 89 mm (3-1/2 in.).

continuously wrapped around the outer circumference of the pipe covering one time and held in place with tape. Wrap strips are installed flush

with each side of wall.

1 hr F Rating is 121 mm (4-3/4 in.). Min fill material thickness for 2 hr F Rating is 152 mm (6 in.).

Hilti Firestop Systems

System No. W-L-8104

WL 8104

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

C

C

L

A

S

S

I

F

I

E

D

Classified by

Underwriters Laboratories, Inc.

to CAN/ULC-S115

Page: 5 of 5

Firestop Configuration D

annular space between the pipe, conduit or tube and the periphery of the opening shall be min. 0 mm (point contact). The annular space between

adjacent penetrants shall be min 89 mm (3-1/2 in.) The following types and sizes of metallic pipes, conduits or tubes may be used:

Rating is 121 mm (4-3/4 in.) Min fill material thickness for 2 hr F Rating is 152 mm (6 in.).

Firestop Configuration E

with an all-service jacket. Longitudinal joints sealed with metal fasteners or factory-applied, self-sealing lap tape. Transverse joints secured with

metal fasteners of with butt tape supplied with product. The min space between adjacent penetrants shall be 51 mm (2 in.).

See Pipe and Equipment Covering - Materials (BRGU) Category in the Building Materials Directory for names of manufacturers. Any pipe covering

meeting the above specifications and bearing the UL Classification Marking with a Flame Spread Index of 25 or less and a Smoke Developed

Index of 50 or less may be used.

F Rating is 121 mm (4-3/4 in.). Min fill material thickness for 2 hr F Rating is 152 mm (6 in.).

Firestop Configuration F

in.).

F Rating is 121 mm (4-3/4 in.). Min fill material thickness for 2 hr F Rating is 152 mm (6 in.).

Firestop Configuration G

be 38 mm (1-1/2 in.).

Rating is 121 mm (4-3/4 in.). Min fill material thickness for 2 hr F Rating is 152 mm (6 in.).

* Indicates such products shall bear the UL or cUL Certification Mark for jurisdictions employing the UL or cUL Certification (such as Canada),

respectively.

Hilti Firestop Systems

System No. W-L-8104

WL 8104

Reproduced by HILTI, Inc. Courtesy of

Underwriters Laboratories, Inc.

January 25, 2016

C

C

L

A

S

S

I

F

I

E

D

Classified by

Underwriters Laboratories, Inc.

to CAN/ULC-S115

Hilti Firestop

Saving lives

through innovation

and education

Product Information

Hilti. Outperform. Outlast.

Hilti (Canada) Corp. 1-800-363-4458 • www.hilti.ca • Hilti Firestop Systems Guide — Canada

Firestop Block

(CFS-BL)

Product description

■ Ready-to-use, intumescent exible block designed to seal medium

to large size openings

Product features

■ Integrated “Grid-Tech” increases Annular Space up to 12”

■ Suitable for re-penetration or new penetrations

■ Economical to use with short installation times

■ Easy installation — no special tools required

■ Ideal for use in oors — no forming required

■ One sided wall systems available

■ Halogen, asbestos and solvent free

■ Operational immediately after installation

■ Smoke resistant

Areas of application

■ Sealing single or multiple penetrations in small to large openings

■ Temporary or permanent sealing of cables and cable tray

penetrations

■ Temporary or permanent sealing of insulated and non-insulated

metallic pipes and combustible pipe penetrations

For use with

■ Walls (UL tested up to max. opening 72" x 36")

■ Floors (UL tested up to max. opening 72" x 36")

■ Concrete, porous concrete, masonry and gypsum wall assemblies

■ Wall assemblies rated up to 4 hours

■ Floor assemblies rated up to 3 hours

Examples

■ Completely dust and ber free rooms and places where electrical

installations are frequently used (ie: computer centers, hospitals,

laboratories, etc.)

■ New buildings in the construction phase and during renovation

■ Large openings containing multiple penetrations as found in

production bays, warehouses, hospitals etc.

Installation instructions for Firestop Block CFS-BL

FILL, VOID OR CAVITY MATERIALFOR USE IN THROUGH-

PENETRATION FIRESTOP SYSTEMS

SEE UL FIRE RESISTANCE DIRECTORY

66Y7

FM

$33529('

)RU3HQHWUDWLRQ)LUH6WRSV

&RQVXOWWKH)DFWRU\0XWXDO5HVHDUFK&RUSRUDWLRQ$SSURYDO*XLGH

R

FILL, VOID OR CAVITY MATERIALS

CLASSIFIED BY

UNDERWRITERS LABORATORIES, INC.

FOR USE IN TROUGH-PENETRATION

FIRESTOP SYSTEMS

SEE UL FIRE RESISTANCE DIRECTORY

66Y7

Notice

• Before handling, read Material Safety Data Sheet and

product label for safe usage and health information.

• Instructions below are general guidelines — always

refer to the applicable drawing in the UL Fire

Resistance Directory or Hilti Firestop Systems Guide

for complete installation information

Opening

1. Clean the opening. Penetration and penetration

supporting structures must be installed in

compliance with local building and electrical

standards.

Application of Firestop Blocks

2a.If no penetrations are located, build up Firestop

Block CFS-BL, firmly seated, within opening.

2b.If penetrations are located, build up Firestop Block

CFS-BL, firmly seated, while cutting blocks with a

knife to suit the placed penetrations.

3. Finish building up Firestop Blocks until entire

opening is filled.

4. Completely fill cable spaces, gaps between blocks

and pipes, and joints with FS-ONE Firestop Sealant

(as required).

5. For maintenance reasons, a penetration seal could

be permanently marked with an identification plate.

In such a case, mark the identification plate and

fasten it in a visible position next to the seal.

Re-installing cables or other penetrations

• Remove or cut the block from the seal.

• Install the penetrant and re-lay the block in

compliance with the approval. Fill gaps and spaces

with FS-ONE Firestop Sealant (as required).

Single cables can be run through joints between

blocks or a hole can be drilled through a block using

a sharpened piece of metal pipe or tubing.

Not for use

• In wet rooms, outdoors or exposed to the weather

or UV radiation (can be done only after applying an

additional silicone coating, i.e. CP 601S).

Storage

• Store only in the original packaging in a location

protected from moisture and direct sunlight

1. Clean opening. 2a. Build up blocks 2b. Cut blocks to

size for penetrations

in place

3. Build up blocks 4. Fill gaps with

FS-ONE, CP 617

or CP 618 putty (as

required).

5. Fasten identication

plate in place (If

required)

Technical Data* CFS-BL

Color

Red

Application temperature

40° F to 104° F (5° C to 40° C)

Temperature resistance

5° F to 140° F (-15° C to 60° C)

Intumescent activation

Approx. 392° F (200° C)

Expansion ratio (unrestricted)

Up to 1:3

Surface burning characteristics

(ASTM E 84-10b)

Flame Spread Index: 10

Smoke Development Index: 15

Sound transmission classication

(ASTM E 90)

STC Rating: 52

Tested in accordance with

• UL 1479 • ASTM E 814 • ASTM E 84 • CAN/ULC-S115

*At 73°F (23°C) and 50% relative humidity

NEW

Grid-Tech!

Issued to:

Hilti Construction Chemicals, Div of Hilti Inc.

5400 S 122

nd

East Ave

Tulsa, OK 74146

This is to certify that

representative samples of

Fill, Void or Cavity Materials

CFS-BL Firestop Block

Have been investigated by Underwriters Laboratories in accordance with

the Standard(s) indicated on this Certificate.

Standard(s) for Safety:

ANSI/UL 1479, "Fire Tests of Through-Penetration Firestops,"

CAN/ULC-S115, "Standard Method of Fire Tests of Firestop Systems."

Third Edition revised March 1, 2010

Additional Information:

See UL On-line Certification Directory at WWW.UL.COM for additional information.

CFS-BL Firestop Block for use in Through-Penetration Firestop Systems as currently described in the

UL Fire Resistance Directory.

Hilti, Inc.

5400 South 122

nd

East Avenue

Tulsa, OK 74146

1-800-879-8000

www.hilti.com

September 24, 2015

To Whom It May Concern:

Re: Hilti CFS-BL, Firestop Block – LEED Info.

Item Number:

2030020

The CFS-BL is manufactured in Kaufering, Germany.

There is no post-consumer or post-industrial content in CFS-BL and it cannot be recycled. The CFS-BL does not contain any

Rapidly Renewable Materials. The VOC content for CFS-BL is 5.4 grams/liter.

CFS-BL is not regulated as a hazardous waste by the Federal EPA Standards. The regulations for the disposal of non-regulated

industrial waste can vary from state to state and even city to city. For this reason, you should consult your local and state

regulatory agencies for direction on disposal.

Please feel free to contact me at (918) 872-3704 if you have questions.

Sincerely,

Jerry Metcalf MPH, CHMM

Sr. Mgr. Safety/Environmental

Hilti Inc.

918 872 3704

Rev. Date: 9/24/15

The manufacturing plant location on this certificate has been provided for LEEDS reporting purposes only. It should never be used

for Country of Origin certification or a representation of compliance/non-compliance with Buy American or Buy America

requirements, as those requirements differ.

The manufacturing plant location(s) identified on the certificate represent standard Hilti catalog products only. “Specially” produced

non-catalog Hilti products may have differing manufacturing plant locations.

Contact your Hilti representative in cases of “specially” produced products for a custom LEEDS certificates

Hilti Firestop

Saving lives

through innovation

and education

Product Information

Hilti. Outperform. Outlast.

Hilti (Canada) Corp. 1-800-363-4458 • www.hilti.ca • Hilti Firestop Systems Guide — Canada

Introduction Applications and Products Selector Guide Through-Penetration Joint Reference Data

Firestop Wrap Strip

(CP 648-E)

Product description

■ An intumescent, exible restop wrap strip for plastic and

insulated pipe penetrations

Product features

■ Highly Intumescent

■ Long length avoids waste

■ Can be continuously wrapped

■ Cost effective

■ Quick and easy closure without tools

■ Ideal for very tight installations

Areas of application

■ Firestopping combustible pipe penetrations

■ Difcult applications where space is limited

■ Penetrations through concrete over metal deck

■ Plastic and insulated penetrations using

PVC, CPVC, ABS, FRPP and PEX

For use with

■ Concrete, masonry, wood oor and gypsum wall assemblies

■ Wall and oor assemblies rated up to 4 hours

Examples

■ Waste water pipes

■ Fresh water pipes

■ Decking penetrations

Technical Data* CP 648-E

Density

Approx. 1.35 g/cm

3

Dimensions (approximate)

3/16" x 1" x 33 ft or

3/16" x 1-3/4" x 33 ft

Color

Black with foil backing

Temperature resistance

–40°F to 212°F (–40°C to 100°C)

Intumescent activation

Approx. 320°F (160°C)

Expansion ratio (unrestricted)

1:40

Tested in accordance with

• UL 1479 • ASTM E 814 • ASTM G21 • CAN/ULC-S115

*At 73°F (23°C) and 50% relative humidity

Installation instructions for CP 648-E

sodfm,ev iJdjfiwhriuh. N|oWE

Z8Z23aw|p3i4e0288u27Āuze

4i5kirdwiloi4jtf-|x-.vbvbvh, ireiv

u9+

12oeoo

CP 648 Brandschutzmansch.

Notice

• Before handling, read Material Safety Data Sheet and

product label for safe usage and health information.

• Instructions below are general guidelines — always

refer to the applicable drawing in the UL Fire

Resistance Directory or Hilti Firestop Systems Guide

for complete installation information

Opening

1. Clean the plastic or insulated pipe penetration.

Expansion of the intumescent material during a fire

closes the plastic or insulated pipe penetration. Very

dirty pipes (ie: with remains of mortar) may lead to

a delay in this closing action. Soiled plastic pipes

or insulated pipe penetrations should, therefore, be

cleaned in the area where the CP 648-E Firestop

Wrap Strip is to be installed.

Application of firestop system

2. Tightly wrap the required number of strips

continuously around the penetrant, and hold in place

with tape.

3. Push the Hilti Wrap Strip into the opening until it is

flush with the substrate surface unless otherwise

required by the UL system. It may be required by

the UL system to clamp, wire or use a Hilti Retaining

Collar to secure the wrap strip in place for some

applications.

4. If the UL system requires a cold smoke seal, then

apply the proper amount of Hilti FS-ONE sealant in

the opening over the wrap strip.

5. For maintenance reasons, a penetration seal can be

permanently marked with an identification plate and

fastened in a visible position next to the seal.

Not for use

• In highly corrosive surroundings

• With unapproved retaining collars, anchors/fasteners

• Outdoors

Storage

• Store only in the original packaging in a location

protected from moisture at temperatures between

23°F and 86°F (–5°C and 30°C).

FILL, VOID OR CAVITY MATERIAL

FOR USE IN THROUGH-PENETRATION

FIRESTOP SYSTEMS

SEE UL FIRE RESISTANCE DIRECTORY

66Y7

FM

$33529('

)RU3HQHWUDWLRQ)LUH6WRSV

&RQVXOWWKH)DFWRU\0XWXDO5HVHDUFK&RUSRUDWLRQ$SSURYDO*XLGH

R

FILL, VOID OR CAVITY MATERIALS

CLASSIFIED BY

UNDERWRITERS LABORATORIES, INC.

FOR USE IN TROUGH-PENETRATION

FIRESTOP SYSTEMS

SEE UL FIRE RESISTANCE DIRECTORY

66Y7

1. Clean penetration 2. Wrap strips around

pipe the specied number

of times

3. Push Wrap Strips

into hole

4. Seal penetration against

smoke with FS-ONE

5. Fasten installation plate

(If required)

Firestop

System

Visit fbcsystemcompatible.com.

FBC™ is a trademark of

the Lubrizol Corporation.

CERTIFICATE OF COMPLIANCE

Certificate Numbe

r

20160829-R13240

Report Reference

R13240

Issue Date

2016-August-29

Bruce Mahrenholz, Director North American Certification Program

UL LLC

Any information and documentation involving UL Mark services are provided on behalf of UL LLC (UL) or any authorized licensee of UL. For questions, please

contact a local UL Customer Service Representative at http://ul.com/aboutul/locations/

Page 1 of 1

Issued to:

Hilti Construction Chemicals, Div of Hilti Inc.

5400 S 122

nd

East Ave

Tulsa, OK 74146

This is to certify that

representative samples o

f

Fill, Void or Cavity Materials

Fill, Void or Cavity Materials Certified for Canada

CP 648E and CP 648S (Product number may be suffixed to

denote size) Wrap Strip for use in Through-Penetration

Firestop Firestop Systems as currently decribed in the UL

Fire Resistance Directory and in the Products Certified for

Canada Directory.

Have been investigated by UL in accordance with the

Standard(s) indicated on this Certificate.

Standard(s) for Safety:

ANSI/UL 1479, "Fire Tests of Through-Penetration

Firestops,"

CAN/ULC-S115, "Standard Method of Fire Tests of Firestop

Systems."

Additional Information:

See the UL Online Certifications Directory at

www.ul.com/database for additional information

Only those products bearing the UL Certification Mark should be considered as being covered by UL's

Certification and Follow-Up Service.

Look for the UL Certification Mark on the product.

Hilti, Inc.

5400 South 122

nd

East Avenue

Tulsa, OK 74146

1-800-879-8000

www.hilti.com

September 24, 2015

To Whom It May Concern:

Re: CP 648 E&S Firestop Wrap Strips – LEED Information

Item Numbers:

304303

304304

304305

304306

304307

304308

304309

The Hilti CP 648 E & S Firestop Wrap Strips are manufactured in Germany.

The Hilti CP 648 E & S Firestop Wrap Strips have a VOC content of 3.1 grams/liter.

The amount of post-consumer or post-industrial content in CP 648 E & S Firestop Wrap Strips is not known. The packaging is

recyclable. The CP 648 E & S Firestop Wrap Strips do not contain any Rapidly Renewable Materials.

The CP 648 E & S Firestop Wrap Strips are not regulated as a hazardous waste by the Federal EPA Standards. The regulations

for the disposal of non-regulated industrial waste can vary from state to state and even city to city. For this reason, you should

consult your local and state regulatory agencies for direction on disposal.

Please feel free to contact me at (918) 872-3704 if you have questions.

Sincerely,

Jerry Metcalf MPH, CHMM

Sr. Manager, Safety/Environmental

Hilti Inc.

(918) 872 3704

Rev. Date: 8/14/15

The manufacturing plant location on this certificate has been provided for LEEDS reporting purposes only. It should never be used

for Country of Origin certification or a representation of compliance/non-compliance with Buy American or Buy America

requirements, as those requirements differ.

The manufacturing plant location(s) identified on the certificate represent standard Hilti catalog products only. “Specially” produced

non-catalog Hilti products may have differing manufacturing plant locations.

Contact your Hilti representative in cases of “specially” produced products for a custom LEEDS certificates.

CERTIFICATE OF COMPLIANCE

Certificate Numbe

r

20160125-R13240

Report Reference

R13240-20160123

Issue Date

2016-JANUARY-25

Bruce Mahrenholz, Director North American Certification Program

UL LLC

Any information and documentation involving UL Mark services are provided on behalf of UL LLC (UL) or any authorized licensee of UL. For questions, please

contact a local UL Customer Service Representative at http://ul.com/aboutul/locations/

Page 1 of 1

Issued to:

HILTI CONSTRUCTION CHEMICALS, DIV OF HILTI INC

5400 S 122ND EAST AVE

TULSA OK 74146

This is to certify that

representative samples o

f

FILL, VOID OR CAVITY MATERIALS

The product covered by this Section of the Procedure is a

two component polyurethane foam Fill, Void or Cavity

Material designated as CP 660 Firestop Foam for use in

Through-Penetration Firestop Systems. The “B”

component, a blended product, is used as received from a

supplier. The “A” component is blended internally.

Have been investigated by UL in accordance with the

Standard(s) indicated on this Certificate.

Standard(s) for Safety:

ANSI/UL 1479-Fire Tests of Through-Penetration

Firestops,CAN/ULC-S115-Method of Fire Tests of Firestops

Systems

Additional Information:

See the UL Online Certifications Directory at

www.ul.com/database for additional information

Only those products bearing the UL Certification Mark should be considered as being covered by UL's

Certification and Follow-Up Service.

Look for the UL Certification Mark on the product.