This manual covers a range of

conventional fire panel and include

system design, installation and

configuration information.

The fire panels covered are

designed in accordance with the

requirements of EN54-2: 1997,

A1:2006, plus the requirements of

EN54-4: 1997, A1:2002, A2:2006.

This publication covers the

Con ven tional fire alarm pan els:

q 2 zone pan el:- 13270-02LB and

75585-02NMB

q 4 zone pan el:- 13270-04LB and

75585-04NMB

q 8 zone pan el:- 13270-08LB and

75585-08NMB

q Fire alarm re peat pan el:

13271-08LB and 75586-08NMB.

The panels are supplied without

bat ter ies.

This manual is intended

for use by installers and

commissioning engineers.

A separate Operating

instructions and Log book

has been supplied along

with this booklet which

must be forwarded on to

the End User.

4188-424 issue 6_Part 1_06-12

Data, In stal la tion and Com mis sion ing guide

Fire Con trol and Re peat pan els

(Con ven tional 2, 4 and 8 Zone panel range)

Content Page

System design ·· .....2

Cables - ····· .....4

Notes to installers .....5

Panel fixing···· .....6

Terminals ···· .....8

Controls & indicators ....9

Power up tests ·· .....10

Installed system tests ...11

Config. con sid er ations ...11

Access levels 2 · .....12

Op er at ing instructions for

Access level 2 func tions ..12

Programming Options ...14

Op er at ing instructions for

Access level 3 func tions ..14

Op er at ing in struc tions for

Ac cess level 4 func tions ..15

Fault indications · .....16

Fault find ing ··· .....17

Specification for the

Control panel··· .....20

Specification for the

Repeat panel··· .....22

Parts list ····· .....23

System design

The fire system design should be

to BS 5839:Part 1:2002 + A2:2008

Code of Practice for system

design installation and servicing.

Supplemented with customer

requirements.

Mains Supply

The control panel mains supply

must be via a fused spur unit

rated:

5A - 1 & 2 Zone panel/Repeat

panel

7A - 4 & 8 Zone panel

Standby Supply

With the recommended batteries

the control panel will provide a

standby supply under mains

failure conditions. A period of

72 hours followed by 30 minutes

of alarm load is possible and is

dependent on the system loading.

24V power supply

The power supply terminals ‘24+

and 0’ may drive external ancillary

equipment and is designed to be

used in conjunction with auxiliary

contacts and common fire and

fault outputs. The maximum

currents are 250mA (1 & 2 zone)

and 500mA (4 & 8 zone). The

supply is monitored for faulty 24V

supply level or fuse blowing.

NOTE: The use of the 24V

supply will affect the panel

standby capability.

Fire De tec tion

(Zone Cir cuits)

Each zone circuit can have up to

3.0mA load. An end-of-line

capacitor unit or bipolar capacitor

is required for zone circuit

monitoring, which must be fitted

after the last detector or manual

call point on the circuit. All

manual call points used must

have a 470 ohms series resistor.

Where a zone circuit is not being

used, the end-of-line capacitor unit

or bipolar capacitor must be fitted

across its terminals in the panel.

System design Fire Panels

2 4188-424 is sue 6_Part 1_06-12

Un-used Zone circuits must

be terminated with an

end-of-line Capacitor unit

or bipolar capacitor

End-of-line Capacitor unit

or bipolar capacitor

RED

BLACK

FIRE DETECTION (ZONE) CIRCUIT

A fire detector head may be fitted

to a diode-base for continuity when

a detector head is removed and

there can be a maximum of up to

20 diode-bases per zone circuit.

MANUAL

CALL

POINT

NOTE: Spur wiring is not permitted off zone circuits.

Zone

Circuit

Zone

Circuit

Control panel

Z1+ Z2+Z1- Z2-

BLACK

RED

FIRE

DETECTOR

Figure 1 Zone circuit - used and unused

IN

IN

1

1

7

7

6

6

5

5

4

4

3

3

2

2

OUT

OUT

IN

1

7

6

5

4

3

2

OUT

IN

1

7

6

5

4

3

2

OUT

IN

1

7

6

5

4

3

2

OUT

LED unit

Base showing

End of Line

device fitted

Base with LED

connection

Standard base shown. Diode

base connection is identical.

Standard base

MCP

Zone

Circuit

Zn+

Zn-

NOTE: LED unit is supplied

with LED module

NOTE: End of line unit

is supplied with panel

Zone

Circuit

Control panel

Zn+

Zn-

Earth continuity

+

-

Control panel

Connection to 17800 range of detector bases are shown here.

1 2 3 4

Vision detector wiring

Standard base

Figure 2 Connection to detectors, cal l points and panel

Alarm (Sounder cir cuits)

To comply with the requirements

of BS 5839: Part 1:2002 +

A2:2008, two or more alarm

sounder circuits should be used

on all installations.

NOTE: All sounder circuits

(sectors) will operate together in

the event of a fire condition.

NOTE: Each sounder output is

0.5A maximum protected by

0.75A fuse.

1 & 2 Zone

Panels

4 & 8 Zone

Panels

1A maximum

Alarm sounder

load per panel

1.5A maximum

Alarm sounder

load per panel

The load must be shared between

the sounder circuits. The alarm

sounder circuits are regularly

pulse monitored for failure. It is

important that the last alarm

sounder is fitted with a 10K Ohm

end-of-line resistor.

The sounder outputs are

monitored in alarm for loss of

supply or multiple sounder output

overloads

Where a sounder circuit is not

being used, the end-of-line resistor

must be fitted across its terminals

in the control panel.

Class Change

A pair of unmonitored ter mi nals

al low only the sys tem alarm

sound ers to be ac ti vated from a

re mote po si tion. It is con sid ered that

the ma jor use for these will be for

class change func tions in schools

and col leges.

Aux il iary Con tacts

These are normally open (NO) and

normally closed (NC) contacts that

change over when the panel goes

into a fire condition. The contacts

are rated at 24V dc 1A for a

resistive load and should not be

used to switch voltages in excess of

50V. The auxiliary circuits should be

powered from an independent

power supply.

NOTE:There is no

indication given at the

panel of class change push

button operation.

Fire Panels System design

4188-424 is sue 6_Part 1_06-12 3

NOTE: Spur wiring is not permitted

off alarm sounder circuits.

Sounder

Sounder

Control panel

Alarm sounders

must be polarised

and suppressed.

S1+

Sn+S1- Sn-

Alarm sounder

must have a

series blocking

diode

Sounder circuit that is

not used is terminated

with an end-of line resistor

ALARM SOUNDER CIRCUIT

End-of-line Resistor

10k Ohms

Control panel

Sn+

Sn-

Earth

continuity

Sounder

Figure 3 Alarm sounder circuit used and unus ed

Class change

100m max.

Cable

distance

Push button switch

or relay pulsed

at 1 second

interval (minimum)

for class change

application

CC1

CC2

Control panel

Figure 4 Class change circuit

Contacts rated 1A@24Vdc

Contacts

change

over occur

with a fire

condition

NC

NC

N0

N0

Auxiliary

contacts

Control panel

100m maximum

cable distance

Figure 5 Auxiliary contacts

Com mon Fire and fault

The common fire output is a

normally open electronic switch

that closes with a fire condition.

The common fault output is a

normally closed electronic switch,

which opens with a fault condition,

this is for a fail safe operation.

Each electronic switch is current

limited, see specification.

Use a relay to provide volt free

contacts.

The +24V & 0V is a power supply

for use with auxiliary contacts,

common fire and common fault

circuits, see specification.

Re peat Panel

A Repeat panel can be connected

in series to the control panel. A

repeat panel duplicates fire and

fault indications together with

system controls.

Cables Fire Panels

4 4188-424 is sue 6_Part 1_06-12

24+

CFT

CFR

0V

Control panel

Current limited

Current limited

Normally closed

electronic switch

Normally open

electronic switch

NOTE: The maximum 24V

relay load is 280mW (Common

Fire) and 500mW (Common Fault).

Use a relay to

provide volt free contacts.

0V

24V+ - 24V+ supply

CFT - Common fault

CFR - Common fire

0V - 0V supply

The Indicator and Relay

shown connected here

are typical examples

of external circuit

Figure 6 Fire

fault & 24V

outputs

Length per circuit Type of circuit Recommended cables, also see BS5839:Part 1 guidance

2m Mains power supply cord see power supply cord

1Km Zone circuit

See BS5839:Part 1:2002 + A2:2008 for guidance

1Km Sounder circuits

100m Auxiliary circuit

100m Common fire and fault circuit

100m Class change circuit

500m total circuit Repeat panel link Belden type - screened 2-core twisted pair

Cables

The guidance of

BS5839:Part 1:2002 + A2:2008,

should be followed.

Generally available electrical

installation cable may be used,

providing the cable is:

q to BS6387

q with no more than 2 - cores

q each core hav ing no less than

1.5mm

2

cross sec tion area

(max i mum 2.5mm

2

).

q with an in her ent or through

metal con duit screen for earth

con ti nu ity in or der to pro duce

elec tri cal pro tec tion and

screen ing.

q hav ing pro tec tion from heat and

me chan i cal dam age.

Power supply cord

The mains supply to the panel

should be wired in 0.75mm

2

cable

with a effective connection to

building service earth continuity

conductor.

R+

R-

Control panel

Repeat panel

Screen must be

connected to panel

R+ R-

Figure 7 Control

to repeat panel

connections

Notes to installers

Check

q The power-up and

com mis sion ing is done by the

ser vic ing or gani sa tion.

q The wires be tween the

ter mi na tion point and ter mi nals

should be short and straight

as pos si ble.

q The ca bles of the fire de tec tion

and alarm sys tem and other

sys tems should usu ally be

sep a rated by at least 160mm,

un less ded i cated con duit or

ducting is used.

q Do not use any part of build ing

struc ture for earthing.

q The ca ble length be tween the

Re peat LED unit and re spec tive

fire de tec tor where used, should

not ex ceed 10m.

q Ca ble Glands should be used

on the equip ment for the mains

sup ply ca ble.

q Un used knock outs on prod uct

en clo sure that have been

re moved, should not be left

open.

Requirements

It is recommended that the

installer follow the general

requirements of:

q BS5839:Part 1:2002 + A2:2008,

which is the code of prac tice

re lat ing to the fire de tec tion and

alarm sys tems for build ings.

q the rel e vant parts of the

BS 7671 Re quire ments for

Elec tri cal In stal la tion.

Second fix

To prevent the possibility of

damage or dirt degrading the

performance or appearance of the

System products, the installation

of second fix items should be

delayed until all major building

work in the area is complete.

Fix tures and fit tings

It is the installers responsibility to

provide:

· adequate fixtures and fittings

for the type of construction

surface onto which a product

is to be installed.

· as an aid to this decision, the

weight and overall size of

each full assembly together

with implications on cable

entries and routing should be

taken into consideration.

NOTE: All these procedures

assume that the cable, gland,

steel box (BESA box) and other

related accessories are provided

by the installer.

As fitted wiring drawings

The installer should acquire:

q site spe cific in for ma tion from

the in ter ested par ties, for de tails

on the lo ca tion of prod ucts for

in stal la tion

q the ac quired in for ma tion

to gether with this guide and the

rel e vant stan dards should be

used to as sist the work.

Earth continuity

To maintain earth continuity, the

cable screen must be continued

through each system device,

whether the earth is connected to

a device or not.

NOTE: The cable from the main

panel to repeat panels if fitted

must be a screened cable.

Refer to Figure 8.

Fire Panels Notes to installers

4188-424 is sue 6_Part 1_06-12 5

4-off earth points

Mains input terminal

block c/w mains fuse

Mains supply

to panel

13-back

13-top

cable entry points

Gland

Earth

drain

Cable

Zone Cable termination

NOTE: Repeat panel link

cable entries are located

at the opposite end to the

mains cable entries, ie on

the Right Hand Side.

Panel backbox

Electronic assembly

Figure 8 Panel cable entry and earth points

Panel fixing

a) Remove panel from its carton.

b) Store the front panel (including

the electronic assembly) and

the metal plates in a safe place

until later.

c) Check the spare parts supplied

with those listed in Table 1.

d) Remove the appropriate

knock-in on the panel case for

cable entry.

e) Hold the panel on the wall in

the desired mounting position

and mark the positions of the

fixing holes. See Figure 9 for

case fixing details.

f) Secure the panel to the wall

using suitable fixings. A top

centre keyhole fixing is

provided on the case to allow

the panel to be hooked whilst

the bottom two fixing points are

located.

NOTE: For details on flush

fixing the panel, see Figure 11.

g) Connect the mains supply

cable to the panel. The cable:

· must be fed through one of

the dedicated mains cable

entry points into the panel.

· must be via an unswitched

fused spur unit, rated 5A for

the 2 Zone Control and

Repeat panels and 7A for 4&8

Zone panels.

· The fused spur isolator cover

should be red and marked:

FIRE ALARM - DO NOT SWITCH

OFF

· The fused spur units must be

fed from a dedicated isolation

switch used for the fire alarm

system only.

h) Wire the system. With the

exception of mains cable, all

other cables should remain

unconnected at the panel. For

the unconnected cable leave

300mm tail wire length and

mark each core identifying its

final point of connection.

The system wiring can be

tested whilst not connected to

the respective terminals at

each system device.

CAUTION: DO NOT undertake

high voltage insulation tests

WITH THE CABLES

CONNECTED to their terminals.

This may damage the electronic

circuitry in the product.

I) Refit the front panel (including the

electronic assembly) into the panel

using four M3 screws and connect

the transformer cable and earth

cable, see Figure 10.

j) Attach the top and bottom metal

plates using four M3 screws, see

Figure 11.

NOTE: Each terminal in a

panel will accept a

maximum conductor size of

2.5mm

2

.

NOTE: The installation of

all outstanding parts is

usually carried out during

Commissioning of the

System.

Panel fixing Fire Panels

6 4188-424 is sue 6_Part 1_06-12

Description

For fuse location

see Figure 12

Quantity supplied with control

panel

Repeat

panel

2 zone 4 zone 8 zone

10K end-of-line resistor 2 4 8

22uF Capacitor unit 2 4 8

End of line label 4 8 16

Fuse T3.15AH250V

ceramic 20 x 5mm

(mains FS1 & battery FS2)

2 2 2 2

Fuse F500mA250V

20 x 5mm (24V FS11)

1 1 1

Battery link 1 1 1 1

Zone designation label 1 1 1 1

M3 screws 8 8 8 8

Table 1 Spare parts supplied with each panel

Dedicated mains

cable entry points

Panel size

395mm wide x 274mm high x 87mm deep

89mm 89mm

19mm

197mm

111mm

4-off

earth points

How to knock-in

a cable entry point

Knock here to open

the entry point

Panel Backbox

Figure 9 Panel fixings

Store all spare parts and loose

components including the

batteries inside the panel carton

and keep in a safe place until

required.

Fire Panels Panel fixing

4188-424 is sue 6_Part 1_06-12 7

Dedicated mains

cable entry points

4-off earth points

Red

Battery connections

Black

Fixing points for the

electronic assembly

Electronic assembly

P1

To To

Transformer Earth

T1A T1B E

Panel Backbox

Transformer

cables

to electronic

assembly

Earth connection

to the electronic

assembly

+ve

-ve

Bottom Plate (instructions printed on plate)

Ribs

NOTE: The metal plates are to be located

under the ribs on the front panel and fixed

in place using M3 screws.

Figure 10 Refitting electronic assembly

378mm wide

245mm high

60mm deep

cross section of

the wall to which

the panel is to be

flush mounted

Control or Repeat

panel

Aperture

Flush

shroud

4.5 mm

diameter holes

12 holes

Figure 11 Installing a flush shroud

Terminals

Terminals Fire Panels

8 4188-424 is sue 6_Part 1_06-12

Zones

FIRE

Faults

System

Power

Earth

Sounder

Disabled

Sound

Alarms

Silence

Alarms

1

2 3

4

5 6

7

8

9

0

v

Test

Access /

Function

1 2 3 4 5 6 7 8

Cancel

Buzzer

Reset

System

CN5 CN6 CN7 CN8 CN9 CN10 CN11 CN12 CN13 CN14 CN15 CN16 CN17 CN18 CN19 CN20 CN21 CN22 CN23 CN24 CN25 CN26 CN27 CN28CN29 CN30

F1 F2 F3 F4 F5 F6 F7 F8

F9 F10 F11

SECTOR 1 SECTOR 2 SECTOR 3 SECTOR 4 SECTOR 5 SECTOR 6 SECTOR 7 SECTOR 8BATTERIES

T1A T1B T2BT2AE NC NC NO NO Z1+ Z1- S1-S1+ Z2+ Z2- S2-S2+ Z3+ Z3- S3-S3+ Z4-Z4+ S4+ S4- Z5+ Z5- S5-S5+ Z6+ Z6- S6-S6+ Z7+ Z7- S7-S7+ Z8-Z8+ S8+ S8- CC1 CC2 24+ 0CFT CFR R+ R-

POWER 1 POWER 2

FS2 (SB)

3.15A

3.15A

3.15A

3.15A

FS3

750mA

750mA

750mA

FS11 (QB)

500mA

500mA

500mA

500mA250V

FS5

750mA

750mA

FS7

750mA

FS9

750mA

FS4

750mA

750mA

750mA

FS6

750mA

750mA

FS8

750mA

FS10

750mA

Fuse

2-Zone panel

4-Zone panel

8- Zone panel

Repeat panel

Fuse marking

SECTOR 1

SECTOR 2

SECTOR 3

SECTOR 4

SECTOR 5

SECTOR 6

SECTOR 7

SECTOR 8

BATTERIES

24V

1 8

All other fuses, ie FS1, FS2 and FS11

are 20mm x 5mm diameter

QB - Quick Blow AS - Anti-Surge

SB - Slow Blow (ie Time Delay)

Fuses

T1A

T1B

E

CFR

24+

CFT

0

CC1

CC2

R+

R-

NC

NC

NO

NO

Zn+

Zn-

To Zone and Sounder

Circuits, where `n' signifies

circuit number 1 to 8

Sn-

Sn+

Auxiliary contacts

1A at 24Vdc resistive

To transformer

Mains input

supply

Software

version

label

P1

P3 to P6

P7

Class change, connect to XEN-FFR

Common fault,

Common Fire

Repeat panel

Panel

P8

EEPROM

Protection

fitted across

pins 1 and 2

Power

Shift

Display

N

The shaded terminal blocks

are not fitted on the Repeat panel.

FS1 (SB)

3.15A

3.15A

3.15A

3.15A

T3.15AH250V

(SB) - Slow blow

ceramic

All sector outputs have resettable 0.75A fuses which do not

need replacing. The individual outputs will recover after

removing the fault. The recovery time is 30 seconds minimum

and it is recommended that the sectors be switched off (Silence Alarms).

Delay

L

Product No: 13270 MAIN PANEL

Rated Voltage: 230V A.C.

Rated Current: 0.3A

Rated Frequency: 50Hz

Mains Fuse: FS1 T3.15AH250V

Manufacture date: xx/xx/xx

by Honeywell

CAUTION

HAZARDOUS VOLTAGES REMAIN

AFTER OPERATION OF FUSE

MAINS

Figure 12 Panel terminals and fuses

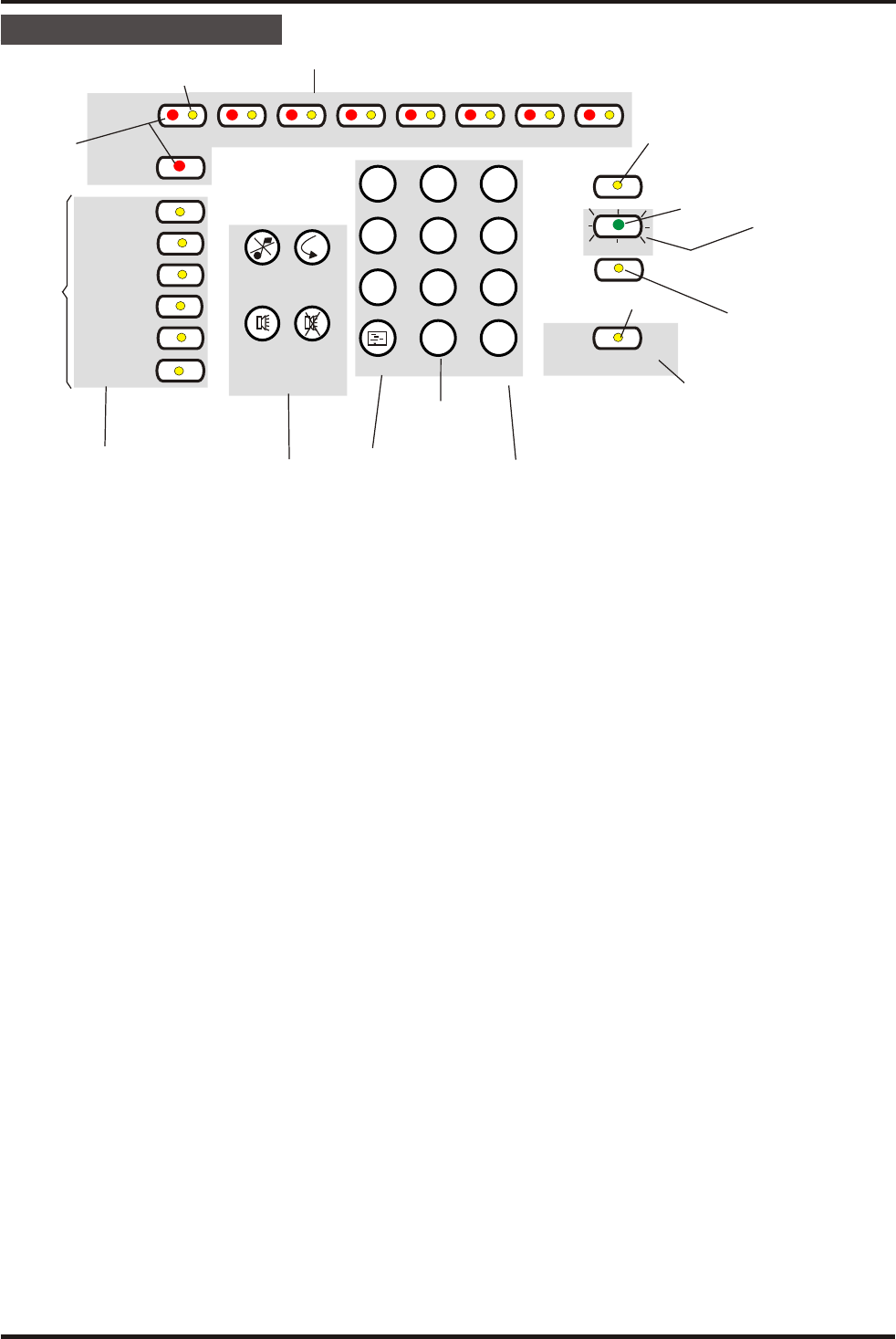

Controls & indicators

Nu meric key pad. Al lows the en try

of nu meric data.

q Shift key. The Shift/Function

key gives ac cess to the main

func tions of the panel.

q Dis play test key. Pressing the

Dis play Test key af ter en ter ing

ac cess code# will ini ti ate a

se quence which il lu mi nates all

the in di ca tors in turn en abling

them to be checked.

# Coded en try is only

re quired if Can cel Buzzer and

Dis play Test func tions are

con fig ured for op er a tion at

Ac cess level 2.

q Can cel Buzzer. Pressing the

Can cel Buzzer but ton af ter

en ter ing ac cess code# will stop

the in ter nal buzzer sound ing.

q Sys tem Re set. The sys tem

re set key when pressed af ter

en ter ing ac cess code will re turn

the sys tem to its nor mal

op er at ing state. If there are

uncleared fires or faults then

these con di tions will re-occur.

q Sound Alarms. Press ing the

Sound Alarms but ton af ter

en ter ing ac cess code will sound

all of the sys tem alarms. Should

only be pressed in an

emer gency or at other agreed

times, ie for sounder tests etc.

Press ing the sound alarms

but ton does not ac tion the

aux il iary re lay.

q Si lence Alarms. Pressing the

Si lence Alarms but ton af ter

en ter ing ac cess code will

si lence the sys tem alarms.

Should only be pressed when

the emer gency is over.

In di ca tors.

q Fire. When lit in di cates that the

sys tem has de tected a fire.

q Fault. When lit or flash ing

in di cates that there is a fault

con di tion on the sys tem which

re quires rec ti fi ca tion.

q Zone Fire/Fault/Disablement.

Red indicator illuminates when

there is a zone fire, it can be a

steady or flash ing indication.

For a zone fault the yel low

in di ca tor is flash ing. A lit zone

yel low in di ca tor along with the

Disabled indicator is used to

show a dis abled zone.

q Sys tem Fault. This in di ca tor

when lit in di cates that there is a

fault in the panel’s pro ces sor.

q Power Fault. When lit or flash ing

in di cates that there is a power

sup ply fault pres ent.

q Earth Fault. This in di ca tor when

lit or flash ing in di cates that there

is an Earth Fault on the sys tem.

q Sounder Fault. When flash ing in

con junc tion with a flash ing fault

in di ca tor in di cates a sounder

fault. When lit in con junc tion with

the dis abled in di ca tor in di cates

that the sound ers are dis abled.

q Dis abled. Illuminates along with

the sounder or the zone

in di ca tors to show a dis abled

con di tion.

q Test. When lit in di cates that the

panel is in Test mode.

q Power. When lit in di cates that

the panel is pow ered up.

q De lay. When lit it in di cates that a

de lay will be ef fec tive af ter

de tec tion of a fire be fore

ac ti va tion of sys tem alarms.

q Ac cess/Func tion. The

Ac cess/Func tion lamp will flash

when the shift key is pressed

and will be lit when the coded

func tions are ac cessed.

Fire Panels Controls & indicators

4188-424 is sue 6_Part 1_06-12 9

Cancel

Buzzer

System

Reset

Sound

Alarms

Silence

Alarms

1

2 3

4

5 6

7

8

9

0

v

Shift or Function

key

Shift

Numeric

keypad

Display test

key

Display

Essential controls

Zones

FIRE

Fault

System

Power

Earth

Sounder

Disabled

Test

Delay

Access /

Function

Normally lit

to indicate

Power supply

healthy

The light is lit when

the Shift/Function key is pressed

or there is an entry to controls

with coded access

ZONE Fire, Fault or Disablement indications

Other Fault

indications

1red

yellow

2 3 4 5 6 7

yellow

yellow

yellow

green

8

Power

yellow

Figure 13 Controls and indications

CONTROLS - only avail able when an ac cess code is en tered.

Power up tests

Connecting the battery will not

power up the panel, power up will

occur after mains is applied.

The total system should be tested

in accordance with the

commissioning requirements of

BS5839:Part 1:2002 + A2:2008 or

other standard specified by the

system purchaser.

NOTE: The commissioning

procedures assume that the

system has been installed as

per instructions in this booklet.

Checks before power up

q Ensure you have 'as fit ted

draw ings'

q check the sys tem has been

in stalled to the pro ject

re quire ments.

q if necessary, ac tion the in staller

to carry out rectification work.

q Remove the EEPROM

protection link from connector

P8, see Figure 14.

Initial power up

a) Disconnect cables to terminals

of zone, sounder, class

change, auxiliary, common fire

and fault circuits. Ensure each

cable is marked for

reconnection to respective

terminals later.

b) Connect end-of-line capacitor

units to zones and end-of-line

resistor units to sounder

circuits for initial power up.

c) Check mains connection and

switch on the mains power to

the control panel.

d) Now connect the battery

supply, see Figure 14.

e) Check the panel provides a

normal healthy indication, with

the green light lit.

Zone circuit tests

a) Transfer the end-of-line

capacitor unit to the last device

(detector or manual call point)

on a zone circuit.

b) Connect a zone cable to the

terminals of a zone circuit.

c) Carry out zone open circuit and

short circuit tests and check

appropriate indications are

given.

d) Repeat the above for other

zone circuits.

Sounder circuit tests

a) Transfer the end-of-line

resistor unit to the last device

on a sounder circuit.

b) Connect a sounder circuit

cable to a sounder circuit

terminals.

c) Carry out sounder open and

short circuit tests and check

appropriate indications are

given.

d) Repeat the above for other

sounder circuits.

EEPROM Protection link

NOTE: Ensure that at the end

of Commissioning and System

tests the EEPROM protection

link is fitted to connector P8,

see Figure 14.

Power up tests Fire Panels

10 4188-424 is sue 6_Part 1_06-12

+

-

Control panel

NOTE: A label is supplied in the spares pack

which can be located on this cover to identify

zone location

Connection for 12V 2.1Ah Batteries

For 1, 2 and 4 zone panels + repeat panel

a) Open the

lower outer cover

b) Remove the

lower inner plate

Instructions + Zone designation

c) Fit the batteries and

connect the battery cables

+

-

Connection for 12V 3.4Ah Batteries

For 8 zone panels

+

-

+

-

Zones

FIRE

Faults

System

Power

Earth

Sounder

Disabled

Sound

Alarms

Silence

Alarms

1

2 3

4

5 6

7

8

9

0

v

Test

Access /

Function

1 2 3 4 5 6 7 8

Cancel

Buzzer

Reset

System

Power

Shift

Display

Day/Night

1 8

P8

EEPROM

Protection

fitted across

pins 1 and 2

Figure 14 Battery installation and EEPROM protection link

Installed system tests

The fire detection and alarm

system should be tested to ensure

it operates to meet the standards

and project requirements.

Configuration

The control panel is factory set to

the requirements of EN54 Parts 2

and 4.

With Test mode A or B active: a

triggered manual call point or fire

detector in the test zone will give:

The operation of the control and

repeat panels and the system may

be re-configured to site specific

needs.

To facilitate tests on the fire

detection and alarm system the

control panel can be set to operate

in a test mode. Note a detector

that is still full of smoke or heat will

retrigger into a fire condition until

the smoke or heat in the area is

cleared.

Sound level test

Sound level tests should be

conducted to standard

requirements and to customer

satisfaction.

Other equipment tests

Where external equipment is

connected to the control panel

using auxiliary, common fire and

fault terminals, then these must be

tested to project requirements.

Zone designation label

a) Write on to the zone

designation label the name that

identifies the area protected by

each zone circuit.

b) Fix the label over the zone

designation part of the lower

inner plate, see Figure 14.

Log book

Fill in the system details on the

first three pages of the log book.

On completion

Ensure the persons responsible

for the system are made aware of:

- system operation

- access codes to controls

- basic controls

- their responsibility

- and the need to log system

events in the log book.

Fire Panels Installed system tests

4188-424 is sue 6_Part 1_06-12 11

Test A

Fire indication for

10 seconds duration

followed by a system

reset

Test B

System alarm sounds for

the first 2 seconds and

at the same time a Fire

indication is given for

10 seconds duration

followed by a system

reset

Table 2 Test mode operation

Config. con sid er ations

Re peat panel config.

q The power up pro ce dure for the

re peat panel is the same as the

main panel.

q The pres ence of a re peat panel

needs to be set up at the main

panel, see Config. and Test

sec tion.

De lay mode

In the Delay mode there is a delay

between detecting a fire and

sounding the alarms to enable the

fire to be investigated. The panel

will upon detection of a fire:

q Il lu mi nate the Com mon fire and

ap pro pri ate zone fire lamps.

q Cause the pan els in ter nal

buzzer to emit the fire tone.

q Ac ti vate the com mon fire and

aux il iary out puts.

q De lays the ac ti va tion of the

sound ers for a configurable

de lay of be tween 1 and 10

min utes in 1 min ute steps.

If the panel is reset during the

delay period, the delay is

cancelled. Also if another fire

occurs in a different zone to the

first fire, the alarms will activate

immediately. You can override the

delay and activate all sounders in

the system by operating the Sound

Alarms button.

False alarm re jec tion

q This is an en hanced fire

alarm rejection al go rithm

de signed to give greater

im mu nity to spu ri ous alarms.

q The Fire alarm rejection

al go rithm should only be used in

con junc tion with rec om mended

de tec tors to guar an tee that the

sys tem will re ject spu ri ous events

but will de tect and an nun ci ate

real fires within 10 sec onds,

which is an EN54-part 2

re quire ment. When set, the

al go rithm ap plies to ALL zones

on the panel.

Visual indications Signals out

Condition Zone

Fire

(1-8)

-Red

Zone

Fault

(1-8) -

Yellow

Test -

Yellow

Power -

Green

Access/

Function

- Yellow

Aux Relay contacts

Normally de-

energised

Common fault -

Normally active

Common fire-

Normally deactive

Test A or B

(Normal)

On On On On Normal Active Deactive

Test A

(Fire)

On On On On Normal Active Deactive

Test B

(Fire)

On On On On Normal Active Deactive

Test condition indications

Access levels 2

To configure the system enter the

appropriate access code.

NOTE: It is only necessary to

enter the access code once,

provided the 2 minute timeout is

not exceeded between button

presses.

Access codes

Factory set codes are:

Access level 2 Code : 123

Depending on how the system is

configured coded entry may be

necessary for test.

The factory codes can be

changed at any time after power

up.

NOTE: It is important to leave

the system in a normal

operating condition on

completion of commissioning.

NOTE: The auxiliary contacts do

not operate in the Test Modes.

Access levels 2 Fire Panels

12 4188-424 is sue 6_Part 1_06-12

Operating Instructions for AL2 functions

How to do a Display test

q Enter the AL2 ac cess code and check that the Access/function lamp is lit.

q Press the shift and dis play but tons and check that all indicators are lit.

How to set the panel to operate in Test mode A

q En ter the AL2 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 3 but tons fol lowed by the num ber of the zone to be placed in test mode.

- Check that the Test indicator is On and the zone fault indicator is lit.

- The zone can be tested without an alarm of fire

How to set the panel to operate in Test mode B

q En ter the AL2 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 4 but tons fol lowed by the num ber of the zone to be placed in test mode.

- Check that the Test indicator is On and the zone fault indicator is lit.

- The zone can be tested with 2 seconds alarm of fire.

How to cancel Test mode A/B

q En ter the AL2 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 5 but tons fol lowed by the num ber of the zone to have test mode cleared.

- The test mode A or B is cancelled.

How to disable a zone

q En ter the AL2 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 1 but tons fol lowed by the num ber of the zone to be dis abled.

- Check that the appropriate Zone fault indicator and the Disabled indicator are lit.

- A detected fire in the disabled zone will not cause the panel to go into fire condition.

How to enable a zone

q En ter the AL2 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 2 but tons fol lowed by the num ber of the zone to be re-enabled.

- The previously disabled zone is re-enabled.

Fire Panels Operating Instructions for AL2 functions

4188-424 is sue 6_Part 1_06-12 13

How to disable sounders

q En ter the AL2 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 1 but tons fol lowed by 0.

- Check that the Sounder and Disabled indicators are lit.

- The Sounder circuits are disabled.

How to enable sounders

q En ter the AL2 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 2 but tons fol lowed by 0.

- The previously disabled sounders are now re-enabled.

How to change AL2 password

q En ter the AL3 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 9001 but tons in se quence and check that the System LED is flashing

q In put the new AL2 ac cess code.

How to change AL3 password

q En ter the AL3 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 9002 but tons in se quence and check that the System LED is flashing

q In put the new AL3 ac cess code.

How to set and unset the Delay mode

q En ter the AL2 ac cess code and check that the Access/function lamp is lit.

q Press the shift and 6 but tons.

- The Delay mode toggles between Delay and No Delay each time this operation is performed.

When Delay mode is selected the Delay lamp is lit.

How to exit from AL2, AL3 or AL4 to AL1

q Press the shift but ton fol lowed by 0.

- Check that the Access/function lamp is extinguished.

- The panel is now in access level AL1.

Programming Options

NOTE: There is a 2 minute

timeout on the access levels. If

this period is exceeded the

code will have to be re-entered.

In order to access the EEPROM,

the EEPROM protection link

needs removing, see Figure 14.

The default settings of the panel

may be changed to suit site

requirements.

Factory set codes:

AL3 code is: 321

This is the code on first power-up

and it can be changed at any time.

AL4 code is: 7426

This code is for the use by the

servicing organisation only.

There is a reset code, 2623

which will reset the AL2 and AL3

codes to their factory settings.

Whilst the EEPROM is

unprotected during programming,

the system fault light will flash to

indicate that the EEPROM

protection link is removed. If

further changes are required, the

sequence shift followed by 9000

must be re-entered.

Once the changes have been

made, the panel must be powered

down and then powered up again

for the changes to take place.

NOTE: After programming is

complete the EEPROM

protection link must be refitted.

Programming Options Fire Panels

14 4188-424 is sue 6_Part 1_06-12

Op er at ing instructions for Access level 3 func tions

To allow Can cel buzzer at ac cess level 1 (de fault set ting)

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 000 000

To allow Can cel buzzer at ac cess level 2

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 000 001

To allow Dis play test at ac cess level 1

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 001 001

To allow Dis play test at ac cess level 2 (de fault set ting)

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 001 002

To allow Test con di tion at ac cess level 2 (de fault set ting)

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 002 002

To allow Test con di tion at ac cess level 3

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 002 003

To allow most re cent alarm in di ca tion as a steady state in di ca tion (de fault set ting)

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 003 000

To allow most re cent alarm as a puls ing in di ca tion

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 003 001

To allow Aux il iary out put to activate in fire and de ac ti vate on re set (de fault set ting)

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 005 000

To allow Aux il iary out put to activate in fire and de ac ti vate on re set and si lence alarms

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 005 001

To change the De lay mode set ting (de fault set ting is 1 min ute)

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 006 and data 000 to 010 in

minutes. Note if a value of greater than 10 minutes is entered, it will be truncated to 10 minutes.

Fire Panels Op er at ing in struc tions for Ac cess level 4 func tions

4188-424 is sue 6_Part 1_06-12 15

To allow False Alarm Re jec tion On/Off (de fault is Off)

q Enter 3 digit AL3 code (default = 321), press shift, Enter 9000 007 followed by 000 to turn the false alarm

rejection algorithm Off.

q Enter 3 digit AL3 code (default = 321), press shift, Enter 9000 007 followed by 001 to turn the false alarm

rejection algorithm On.

To enter num ber of connected Re peat panels (de fault set ting is 0) - TO BE SET AT MAIN PANEL

q Enter 3 digit AL3 access code (default = 321), Press Shift, Enter data 9000 009 001

Op er at ing in struc tions for Ac cess level 4 func tions

CAUTION: These AL4 functions are for trained engineers only and normally

access to these functions is NOT required.

How to set Non Latching Zone con fig u ra tion (de fault set ting is all zones are latch ing)

q A non latching zone fire condition will not action the auxiliary relay.

Enter 4 digit AL4 access code (7426), Press Shift, Enter data 9000 032 and data as follows:

Decimal equivalent of eight bit number where a ‘1’ signifies a latching zone and a ‘0’ signifies a non latching

zone, also bit 0 corresponds to zone 1 and bit 7 corresponds to zone 8.

E.g. Requirement eight bit number data

All Zones non latching 00000000 000

Zone 1 latching, all others non latching 00000001 001

Zones 3,5,6 latching, all others non latching 00110100 052

All Zones latching 11111111 255

How to set Re set Si lence Con fig u ra tion (de fault si lence alarms be fore re set)

q Enter 4 digit AL4 access code (7426), Press Shift, Enter data 9000 033 followed by 000 for a Reset Silences

and 001 for UK Linking.

How to set Sound/Re sound alarms con fig u ra tion (de fault is sound alarms at any time)

q Enter 4 digit AL4 access code (7426), Press Shift, Enter data 9000 034 followed by 000 for a Sound Alarms

at any time and 001 for Resound only.

How to set Zone short cir cuit con fig u ra tion (de fault is short cir cuit seen as fault)

q Enter 4 digit AL4 access code (7426), Press Shift, Enter data 9000 035 data as follows:

Decimal equivalent of eight bit number where a ‘1’ signifies a zone short circuit being seen as a fire and a ‘0’

signifies a zone short circuit being seen as a fault, also the bit 0 corresponds to zone 1 and bit 7 corresponds

to zone 8.

E.g. Requirement eight bit number data

For all Zones - short circuit signifies a fault 00000000 000

Zone 1 - short circuit signifies a fire 00000001 001

Zones 3,5&6 - short circuit signifies a fire 00110100 052

All Zones - short circuit signifies a fire 11111111 255

How to set the num ber of zones used (de fault is 8 zone)

q Enter 4 digit AL4 access code (7426), Press Shift, Enter data 9000 036 followed by data as follows:

001 for One zone panel, 002 for Two zone panel, 004 for Four zone panel and 008 for Eight zone panel.

How to change Charger Out put level (de fault is 128)

q Enter 4 digit AL4 access code (7426), Press Shift, Enter data 9000 037 followed by a number between 000

and 255.

How to change the Re set Du ra tion (de fault is 010)

q Enter 4 digit AL4 access code (7426), Press Shift, Enter data 9000 038 followed by a number between 000

and 100, in tenths of a second.

Fault indications Fire Panels

16 4188-424 is sue 6_Part 1_06-12

Fault indications

All fault repairs should be

carried out by the

servicing organisation.

In a fault condition:

· the common Fault light

is lit

· appropriate Fault light

is also lit

· internal Fault Buzzer sounds

intermittent tone

· Multiple faults are

simultaneously annunciated

when this does not cause

confusion.

NOTE: Normally the fault lights

will be automatically extinguished

once the fault condition is

rectified.

NOTE: If the system detects a

fire during a fault condition the

fault indicators may be

extinguished.

How to si lence the fault

buzzer

q Press the 3 digit code, if

re quired and then press Can cel

Buzzer.

q Notice the buzzer is silenced

but visual indications remain

active.

NOTE: The sounder circuits

are pulse monitored for

failure.

Cancel

Buzzer

System

Reset

Sound

Alarms

Silence

Alarms

1

2 3

4

5 6

7

8

9

0

v

Shift or Function

key

Shift

Numeric

keypad

Display test

key

Display

Essential controls

Zones

FIRE

Fault

System

Power

Earth

Sounder

Disabled

Test

Delay

Access /

Function

Normally lit

to indicate

Power supply

healthy

The light is lit when

the Shift/Function key is pressed

or there is an entry to controls

with coded access

ZONE Fire, Fault or Disablement indications

Other Fault

indications

1red

yellow

2 3 4 5 6 7

yellow

yellow

yellow

green

8

Power

yellow

Figure 15 Fault indicators

Faults Cause

What is a Zone

fault?

A zone fault occurs when a zone circuit cable is open

circuit or short circuit, or the end-of-line capacitor unit

has been disconnected or a detector has been

removed.

What is a

Sounder fault?

A sounder fault occurs when a sounder circuit cable

is open circuit or short circuit, or the end-of-line

resistor unit has been disconnected.

What is a Mains

power fault?

A mains failure occurs when the mains power supply

to the panel is removed. This can occur on mains

fuse failure or mains supply disconnection.

What is a Battery

power fault?

A battery supply failure occurs when the battery

supply to the panel has failed (due to aging process)

or battery voltage is too low or is disconnected or the

battery fuse has failed.

What is an Earth

fault?

An earth fault occurs when there is an electrical path

for current flow from the system to earth connections.

What is a Repeat

panel fault?

A Repeat Panel fault occurs when a fault is detected

within the Repeat Panel

What is a Repeat

panel link fault?

A repeat panel link fault occurs when there is a

communication failure between the control and

repeat panels or if the link has been removed or

damaged.

What is a System

Fault?

A system fault occurs in the event that the

microprocessor or software fails.

What is a charger

fault?

A charger fault occurs when the charger will not

switch off or will not provide charge when on.

What is a power

fault?

A power fault occurs when there is an incorrect 24V

level or fuse failure. Also occurs if the sounder output

supply is at the incorrect level or overloaded during

alarm condition.

Table 3 Types of faults

Fault find ing

Fire Panels Fault find ing

4188-424 is sue 6_Part 1_06-12 17

Is the Green

Power Indicator lit steadily

and are all other indicators

extinguished?

Are the fire/zone

fire indicators lit?

Yes

Yes

Is the Test indicator lit?

Yes

Are the Fault

and Power fault indicators lit

or flashing?

Yes

Are the Fault

and Earth Fault indicators lit or

flashing?

Yes

Panel is in normal

operating condition

Refer to Operating

Instructions

Are the Fault

and Sounder Fault

indicators flashing?

Yes

Are the Fault

and Zone Fault indicators

flashing?

Yes

Are the

Fault and Access/

Function indicators

pulsing?

Yes

Are the Fault

and System Fault

indicators On and is the

Power On indicator

O

n

or flashing?

Yes

Are the Zone

Fault and Disabled

indicators lit?

Are the Sounder

Fault and Disabled

indicators lit

Refer to Specialist help

Yes

Yes

Refer to the Test

mode, see Page 11

18

18

Refer to the PSU Fault

Indications table, Page

Refer to the Earth

Fault Indications table,

Page

Refer to the Zone/

Sounder Indications

table, Page

Refer to the Repeat

Panel Faults table, Page

Refer to the System

Fault (Software) table,

Page

Refer to Zone/

Sounder

Indications

table, Page

19

19

19

19

PSU Fault In di ca tions

Earth Fault In di ca tions

Fault find ing Fire Panels

18 4188-424 is sue 6_Part 1_06-12

At Main Panel

Green Power Indicator Power Fault Indicator Meaning

Steady Off No PSU Faults

Slow Flash Slow Flash Mains failed (Common Fault indicator also flashes to save batteries*)

Slow Flash Fast Flash Battery disconnected/Battery fault or Charger fault

Slow Flash Steady Auxiliary supply/sounder output supply fault

* If Access/Function indicator flashes slowly, there is either a comms fault, an earth fault or a PSU fault on the Repeat Panel.

At Repeat Panel

Green Power Indicator Power Fault Indicator Meaning

Steady Off No PSU Fault in either Main Panel or Repeat panel

Steady Slow Flash Mains failed at Main Panel

Steady Fast Flash Battery disconnected/Battery fault/Charger fault at Main Panel

Steady Steady Auxiliary supply/sounder output supply fault at Main Panel

Slow Flash Slow Flash Mains failed at Repeat Panel

Slow Flash Fast Flash Battery disconnected/Battery fault/Charger fault at Repeat Panel

* If Access/Function indicator flashes slowly, there is a comms fault, between the Main Panel and the Repeat Panel.

NOTE: If there is a PSU fault at the Main Panel and the Repeat Panel, then priority is given to the fault at the

Main Panel

At Main panel

Fault -

Yellow

Earth -

Yellow

Power -

Green

Buzzer Auxiliary relay contacts

normally de-energised

Common fault -

normally active

Common fire -

normally deactive

Earth fault

indications

Steady Pulse

Slowly

On Pulse

Slowly

Normal Deactive Deactive

NOTE: If a Repeat panel is connected, the ACCESS/FUNCTION lamp will pulse slowly as well.

At Repeat Panel

Earth Fault Indicator

Off No earth fault at the Repeat Panel or the Main Panel

Steady Indication Earth fault local to the Main Panel

Fire Panels Fault find ing

4188-424 is sue 6_Part 1_06-12 19

Zone/Sounder Indications

Re peat Panel Fault In di ca tions

Sys tem Fault (Soft ware) In di ca tions

Visual Indications Audible

Indications

Signals out

Condition Zone

Fault

(1-8) -

Yellow

Fault -

Yellow

Sounder

- Yellow

Disabled

- Yellow

Power -

Green

Buzzer Aux Relay

contacts

Normally

de-

energised

Common fault -

Normally active

Common

fire-

Normally

deactive

Zone

fault

Pulse

slowly

Steady On Pulse slowly Normal Deactive Deactive

Sounder

fault

Steady Pulse

slowly

On Pulse slowly Normal Deactive Deactive

Disable

zone

On On On Normal Active Deactive

Disable

Sounder

On On On Normal Active Deactive

Visual indications Audible

indication

Signals out

Condition Fault -

Yellow

Power -

Green

Access/

Function -

Yellow

Buzzer Aux Relay contacts

Normally de-energised

Common fault -

Normally active

Common fire-

Normally deactive

Repeat

Panel Link

Fault

Steady On Pulse

slowly

Pulse

slowly

Normal Deactive Deactive

Visual indications Audible

indication

Signals out

Condition Fault -

Yellow

System -

Yellow

Power -

Green

Buzzer Aux Relay contacts

Normally de-energised

Common fault -

Normally active

Common fire-

Normally deactive

Software

system

fault

On On On (Pulses

at Repeat

panel)

On Normal Deactive Deactive

Note: Batteries are not supplied with some panels

Number of Zone (detection) circuits 1 - Zone panel 2 - Zone panel 4 - Zone panel 8 - Zone panel

Zone circuit voltage range

19V to 25.5V

Zone circuit load (maximum)

Maximum Quiescent current: 3.0mA per zone OR

EN54 compliance limitation: 32 devices OR

Maximum of 20 diode bases per zone

(Short circuit current limited to < 20mA)

Number of Sounder circuits

2 2 4 8

Sounder circuit (shared load)

0.5A per output, 1A max shared load

@ 24V +2V -2V with mains present

(24V +2V -4V battery only)

Sounder circuit fuse

0.75A resettable

End-of-line unit

Zone circuit: Capacitor (diode) unit Sounder circuit: 10K ohms resistor

OR Biploar Capacitor

Flush fixing kit 13270-29 (Cut out required 378mm wide x 245mm high x 60mm deep)

Colour

Front cover - Grey RAL 7000 (standard)

Assembled panel size (in mm)

395 wide x 274 high x 87 deep

Weight (with batteries) approximate

5.8kg 5.8kg 5.8kg 6.2kg

Operating temperature and humidity

0 - 40

o

C low to +95% RH non condensing

Storage temperature and humidity

-5

o

C to +50

o

C low to +95% RH condensing

Standards

EN54-2: 1997, A1:2006 plus EN54-4: 1997, A1:2002, A2:2006

Approvals

BSI approval acquired

Emission

BS EN50081-1:1992: Part 1 Residential, Commercial & Light industry

Class B limits

Immunity

BS EN50130-4: 1996: Part 4 Alarm systems : Electromagnetic compatibility

Product family standard: Immunity requirements for components of fire, intruder

and social alarm systems

IP rating (BS5490)

IP31 (indoor)

Knock-In cable entry points

13 - top & 13 - back

Terminal size

2.5mm

2

maximum

Battery standby with 1mA load per

zone and 1A total sounder alarm load

72hr standby plus 0.5hr with alarm load

Auxiliary contacts

(operates with fire)

Pair of normally closed (NC) and a pair of normally open (NO) contacts rated

1A @ 24V dc resistive load (Maximum 100m cable distance)

Common Fault

Open collector - normally On (35mA limit)

Common Fire

Open collector - normally Off (16mA limit)

Class change

Normally open push button, up to 100m cable distance away from the panel

24V Power supply (Monitored) 250mA maximum at 24V dc +2V, -4V 500mA maximum at 24V dc +1.5V, -4V

User access: By means of code entry

via numeric key pad

(AL1 Authorised user - No code is

required)

AL2 Site security 3 digit code - 123

AL3 Site engineering 3 digit code - 321

AL4 Engineers 4 digit code - 7426

Reset AL2 & AL3 codes 4 digit code - 2623

Key pad button controls Sound alarm, Silence alarm, System Reset & Cancel buzzer & numeric keypad.

Buzzer for local audible indications Fire & System Fault - continuous sound Fault - intermittent sound

(via piezoelectric buzzer operating at 2 or 2.5KHz 70dB(A) at 1m)

Visual indications

FIRE & ZONES-fire (Red LEDs ‘lights’)

ZONES-fault, Fault, System, Power, Earth, Sounder, Disable, Test, Power,

Access/Function (Yellow LEDs ‘lights’)

Power on (Green LED ‘lights’)

Delay ( Yellow LED ‘lights’)

Repeat panel connections via serial port, see also repeat panel specification

Specification for the Control panel Fire Panels

20 4188-424 is sue 6_Part 1_06-12

Specification for the Control panel

Fire Panels Specification for the Control panel

4188-424 is sue 6_Part 1_06-12 21

Spec i fi ca tion for con trol panel’s Power sup ply

The control panel consists of single board containing both the control and indicating equipment and the power

supply. A 50VA mains transformer provides a low voltage (30Vac) supply into the power supply circuits. The on

board power supply circuits produce a regulated 24V dc supply, a 24V sounder supply and a battery charger

output.

Note the control and monitoring of the power supply unit is under direct control of the microprocessor of the

control and indicating equipment.

Mains supply

Mains

230V AC +10% -15% 50Hz

Fused at 3.15A Ceramic Time delay

Typical standby power 6W

Maximum alarm power <60W (8 zone panel)

Internal supply

24V supply (Feeds current limited

zone circuit & 24V fused output)

24V dc +2V -2V (or 24V +2V -4V battery operation)

current limited

<5% ripple voltage

24V Sounder supply (Feeds fused

sounder circuit)

24V dc +2V -2V (24V +2V -4V battery operation)

Current limited

<5% ripple voltage

Battery Charger Float voltage 27.3V +1% -1% @ 20degC

Compensation -36mV/K (nominal)

Current limited @ 400mA +20% -20%

Fused @ 3.15A Ceramic Time delay

Reverse protection

Use the Battery Standby Calculator sheet available from 'www.gentexpert.co.uk' to determine the site specific battery

standby capability of the system.

Battery supply

Approved Batteries 12V, 2.1Ah POWERSONIC

12V 3.4Ah POWERSONIC

Type and capacity Sealed lead acid (value regulated)

2x12V, 2.1Ah min to 3.4Ah* max (1,2&4 zone panels)

2x12V, 3.4Ah*max (8 zone panel)

* max capacity limited by internal panel size

Maximum current 1.6A (no mains present)

Final voltage 21.6V

Installation requirements As per control panel

EN54 Part 4 data I min -> 120uA

I maxa -> 21.6mA

I maxb -> 1.5A

Ri max-> 2W

UVLO -> 18.5V ± 1.5V

Specification for the Repeat panel Fire Panels

22 4188-424 is sue 6_Part 1_06-12

Specification for the Repeat panel

Number of Zones

8 - Zone (standard size)

Colour

Front cover - Grey RAL 7000

Assembled panel size (in mm)

395 wide x 274 high x 87 deep

Weight (with batteries) approximate

5.8kg (2.1Ah battery) / 6.2Kg (with 3.4Ah battery)

Operating temperature and humidity

0 - 40

o

C low to +95% RH non condensing

Storage temperature and humidity

-5

o

C to +50

o

C low to +95% RH condensing

Approvals

Not applicable

Emission

BS EN50081-1:1992: Part 1 Residential, Commercial & Light industry

Class B limits

Immunity

BS EN50130-4: 1996: Part 4 Alarm systems : Electromagnetic compatibility

Product family standard: Immunity requirements for components of fire,

intruder and social alarm systems

IP rating (BS5490)

IP31 (indoor)

Flush fixing kit

13270-29 (Cut out required 378mm wide x 245mm high x 60mm deep)

Mains operating voltage

230V ac +10% -15% 50Hz

Knock-In cable entry points

Top & back entries

Terminal size

2.5mm

2

maximum

Battery supply (sealed lead acid)

2-off12V 2.1Ah - 3.4Ah (See applicable batteries as listed for Control panel

Standby duration

72hr standby

User access: By means of code entry

via numeric key pad

(AL1 Authorised user - No code is

required)

AL2 Site security 3 digit code - 123

AL3 Site engineering 3 digit code - 321

AL4 Engineers 4 digit code - 7426

Reset AL2 & AL3 codes 4 digit code - 2623

NOTE: Only a limited number of functions are accessible at the repeat panel.

Key pad button controls Sound alarm, Silence alarm, System Reset & Cancel buzzer & numeric

keypad.

Buzzer for local audible indications Fire & System Fault - continuous sound Fault - intermittent sound

(via piezoelectric buzzer operating at 2 or 2.5KHz 70dB(A) at 1m)

Visual indications

FIRE & ZONES-fire (Red LEDs ‘lights’)

ZONES-fault, Fault, System, Power, Earth, Sounder, Disable, Test, Power,

Access/Function (Yellow LEDs ‘lights’)

Power on (Green LED ‘lights’)

Delay (LED ‘lights’)

Repeat panel (standard 8 zone)

A maximum of 1 repeat panel can be connected in series with the control

panel

Repeat panel connections

via serial port

Fire Panels Parts list

4188-424 is sue 6_Part 1_06-12 23

Parts list

Panels

Part number Description

# - less batteries

13270-02LB 2 Zone control panel #

75585-02NMB 2 Zone control panel #

13270-04LB 4 Zone control panel #

75585-04NMB 4 Zone control panel #

13270-08LB 8 Zone control panel #

75585-08NMB 8 Zone control panel #

13271-08LB Repeat panel #

75586-08NMB Repeat panel #

13270-29 Panel flush fixing kit

Au to matic Fire De tec tors

Part number Description

178xx range

17840-01 Optical Smoke Detector

17850-01 Fixed Temperature (58

o

C) Heat

17860-01 Rate of Rise Heat Detector

17870-01 High Temperature Detector

17800-01 Base (without diode)

17801-01 Base (with diode)

17800-02 Low profile base (without diode)

17801-02 Low profile base (with diode)

07011-40 Optical Beam reflective

` 50m to 100m

NOTE: The beam detector should be powered from

an external 24V power supply. This arrangement

requires a reset switch in series with the supply.

Vision range

Part number Description

2020P Optical Smoke detector

2020PT Optical Heat detector

2020F Fixed Temp Heat detector

2020HF High Temp Heat detector

2020R Rate of Rise Heat Detector

2020B Standard Detector Base

2020BSD Standard Det. Base with diode

2020DB Deep Detector Base

2020DBSB Deep Detector Base with diode

72499-24NM Circular remote LED

ZF18 Square remote LED

17899-44 Repeat Relay

Man ual call points (MCP)

Part number Description

XENS-850 or Flush MCP 470 Ohms Glass

MCP1A-R470FG-01

XENS-805 or Surface MCP 470 Ohms Re-settable

MCP1A-R470SF-01

XENS-829 or Weatherproof MCP 470 Ohms resistor

MWCP1A-R470SG-01 Glass

XENS-807 Key Operated, Surface Mounted c/w

backbox

XENS-891 Spare Glasses for MCP XENS-800

(Pack of 10)

XENS-890 Resettable element for XENS-800

and XENS-805 (pack of 10)

XENS-892 Hinged protective cover for use on

XENS-800 range (pack of 10)

XENS-895 Surface Backbox for XENS-800 range

of MCP (pack of 10)

XENS-893 Replacement keys for XENS-807

K/S MCP (pack of 10)

XENS-899 Pack of test keys (pack of 10)

71150-62NM MCP red surface mounted for

NO and NC connections

24Vdc Alarm sig nals

Part number Description

12141-04 Electronic bell (red) IP40

02601-31 Squashni Sounder 24Vdc 18mA

IP54 93dBA @ 1m

02519-52 Bedhead Sounder 24Vdc 18mA

(white) 97dBA @ 1m

C3IP-SN-R IP65 Electronic Sounder

Red (100dBA)

C3IP-SN-W IP65 Electronic Sounder

White (100dBA)

C3-SN-R IP31 Electronic Sounder

Red (100dBA)

C3-SN-W IP31 Electronic Sounder

White (100dBA)

C3IP-SN-ST-RR IP65 Electronic Sounder/Strobe

Red (100dBA)

C3IP-SN-ST-WR IP65 Electronic Sounder/Strobe

White (100dBA)

C3-SN-ST-RR IP31Electronic Sounder/Strobe

Red (100dBA)

C3-SN-ST-WR IP31 Electronic Sounder/Strobe

White (100dBA)

C3-VP-ST-RR IP31Voice sounder/Strobe

Red (100dBA)

C3-VP-ST-WR IP31 Voice sounder/Strobe

White (100dBA)

C2IP-ST-RR IP65 Ultra Low current Strobe

(5mA) red body/red lens

by Honeywell

0086

Gent by Honeywell

Hamilton Industrial Park, 140 Waterside Road, Leicester LE5 1TN, UK

0086-CPD-553764

Xenex

EN54-2: 1997, A1:2006

Control and Indicating equipment for fire detection and fire alarm systems

in buildings

7.8 Output to Fire alarm device(s)

7.10 Test Conditions

7.11 Delays to action outputs

EN54-4: 1997, A1:2002, A2:2006

Power supply equipment for fire detection and fire alarm systems in

buildings.

Other technical data: see documents in project file 6304, held by the

manufacturer.

At the end of their useful life, the packaging,

product and batteries should be disposed of

via a suitable recycling centre and in

accordance with national or local legislation.

Do not dispose of with your normal household waste.

Do not burn.

WEEE Directive:

At the end of their useful life, the packaging,

product and batteries should be

disposed of via a suitable recycling centre.

24Vdc Alarm sig nals

Part number Description

CONV-IP-SN-R IP55 Electronic Sounder

Red 100 dBA

CONV-SN-R IP31 Electronic Sounder

Red 100dBA

CONV-SN-ST-RR IP55 Electronic Sounder Strobe

Red body Red lens 100 dBA

CONV-IP-ST-RR IP55 Ultra low current Strobe

Red body Red lens

CONV-IP-VP-R IP55 Voice Enhanced Electronic

Sounder Red (100 dBA)

CONV-IP-VP-ST-RR IP55 Voice Enhanced

Electronic Sounder and Strobe

Red Body Red Lens (100 dBA)

74451-24NM Multitone Low Profile Sounder,

Red with shallow base

74452-24NM Multitone Low Profile Sounder,

Red with deep base

74456-24NM Sounder base, White 3 tone

74455-24NM Bedhead Sounder

74456-61NM Sounder base cover plate

74430-88NM 6" Electronic bell 24V dc

Red IP40

74432-88NM 6" Electronic bell, weather

resistant Electronic bell,

24V dc Red IP55

Panel Ac ces so ries

Part num ber De scrip tion

XENS-BATT-12 2 x 12V 2.1Ah bat tery

(for 1, 2 & 4 zone

panel plus re peat panel)

XENS-BATT-48 2 x 12V 3.4Ah bat tery

(for 8 zone panel)

XEN-FFR Fire fault relay unit

Parts list Fire pan els

Gent by Honeywell reserves the right to revise this publication from time to time and make changes to the

content hereof without obligation to notify any person of such revisions of changes.

Hamilton Industrial Park, Waterside Road, Leicester LE5 1TN, UK Website: www.gent.co.uk

Telephone: +44 (0) 116 246 2000 Tech. Support: www.gentexpert.co.uk Fax (UK): +44 (0)116 246 2300

4188-424 issue 6_Part 1_06-12