Flywheelapparatuslabreportdiscussion

Experiment:DeterminationofmomentofInertiaofaFlyWheelTheory:Theflywheelconsistsofaweightyrounddisc/massivewheelfixedwithastrongaxleprojectingoneitherside.Theaxleismountedonballbearingsontwofixedsupports.Thereisalittlepegontheaxle.blankcheckregisterpdfOneendofacordislooselyloopedaroundthepeg

anditsotherendcarriestheweight-hanger.Suppose,theangularvelocityofawheelisωanditsradiusr.Thenlinealvelocityofthewheelis,v=ωr.IfthemomentofinertiaofabodyisIandthewheelisrotatingaroundanaxle.Thenitsrotationalkineticenergy,E=½Iω2.Apparatus:Anironaxle,aheavywheel,someropes,amass,stopwatch,meter

scale,slidecalipers.Descriptionoftheapparatus:Theflywheelwassetasshownwiththeaxleoftheflywheelstraightorparallel.Apolystyrenetilewasplacedonthefloortoavoidthecollisionofthemassonthefloor.(1)Firstofall,letusmeasuretheradiusoftheaxlebyaslidecaliper.(2)Thenforthedeterminationofanumberofrotationamarkby

chalkisputontheaxleandaropeiswoundontheaxle.AttheotherendoftheropeamassmisfastenedandifitisdroppedfrompositionR,thewheelafterrotatingafewtimes,theweightwiththeropewillfalltopositionS.Thewheelmakesm1numberofrotationtotouchthepointSandtimeforthisdropisnotedfromthestopwatch.Nowthe

ropeisagainwoundontheaxleandthemassisfastenedontheotherendoftherope.FrompositionRthemassisallowedtofalltothegroundandassoonasittouchestheground,thestopwatchisstarted.Whentheaxlecomestorestthestopwealthisstopped.Totaltimeandthenumberofrotationofthewheelbeforeitcomestorestarenotedi.e.,

atotalnumberofrotation(n2)asnoted.Table1:radius(r)oftheaxleBTable2:DeterminationoftimeandnumberofrotationCalculation:Iftheaxistakestimetforn2numberofrotation,theaverageangularvelocity,ω2=(2πn2)/tTheaxleacquireszerovelocitywithuniformretardationfromangularvelocityω,soitsaverageangularvelocity,ω2=(ω

+0)/2=ω/2or,(2πn2)/t=ω/2or,ω=4πn2radS-1Then,I=(2mgh–mω2r2)/ω2(1+n1/n2)=…..large_print_word_search_for_seniors_printable.pdfg.cm2=…..Kg.m2Byinsertingthevalueofn2,ωcanbefoundout.Byincreasingthevaluesofm,ω,r,h,n1,n2andginanequation;themomentofinertiaoftheheavywheelcanbefound

out.Precautions:Intheaxle,aropeistobewoundedinsuchawaythatwhileunwindingfromthewheelitcaneasilydropontheground.Thereshouldbetheleastfrictionintheflywheel.Anumberofrotationnandtimetistobeunwiredcorrectly.Thelengthofthestringshouldbelessthantheheightofaxlefromthefloor.Height‘h’istobe

measuredfromthemarkontheaxle.‘h’istobemeasuredcorrectly.Thereshouldbenokinkinstringandstringshouldbethinandshouldbewoundevenly.Thestopwatchshouldbestartedjustafterdetachingtheloadedstring.Applications:Themainfunctionofaflywheelistomaintainanearlyconstantangularvelocityofthecrankshaft.Asmall

motorcanacceleratetheflywheelbetweenthepulses.Thephenomenonofprecessionhastobeconsideredwhenusingflywheelsinmovingvehicles.Flywheelsareusedinpunchingmachinesandrivetingmachines.ExperimentNo.15Objective:Todeterminethemomentofinertiaofaflywheel.Apparatus:Flywheel,weighthanger,slottedweights,

stopwatch,metrescale.Theory:Theflywheelconsistsofaheavycirculardisc/massivewheelfittedwithastrongaxleprojectingoneitherside.Theaxleismountedonballbearingsontwofixedsupports.Thereisasmallpegontheaxle.Oneendofacordislooselyloopedaroundthepeganditsotherendcarriestheweight-hanger.Let"m"bethe

massoftheweighthangerandhangingrings(weightassembly).Whenthemass"m"descendsthroughaheight"h",thelossinpotentialenergyisTheresultinggainofkineticenergyintherotatingflywheelassembly(flywheelandaxle)isWhereI-momentofinertiaoftheflywheelassemblyω-angularvelocityattheinstanttheweightassembly

touchestheground.Thegainofkineticenergyinthedescendingweightassemblyis,Wherevisthevelocityattheinstanttheweightassemblytouchestheground.TheworkdoneinovercomingthefrictionofthebearingssupportingtheflywheelassemblyisWheren-numberoftimesthecordiswrappedaroundtheaxleWf-workdonetoovercome

thefrictionaltorqueinrotatingtheflywheelassemblycompletelyonceThereforefromthelawofconservationofenergywegetOnsubstitutingthevalueswegetSignuptoviewthefulldocument!lock_openSignUpNowthekineticenergyoftheflywheelassemblyisexpendedinrotatingNtimesagainstthesamefrictionaltorque.ThereforeandIfr

istheradiusoftheaxle,thenvelocityvoftheweightassemblyisrelatedtorbytheequationSubstitutingthevaluesofvandWfweget:NowsolvingtheaboveequationforIWhere,I=MomentofinertiaoftheflywheelassemblyN=Numberofrotationoftheflywheelbeforeitstoppedm=massoftheringsn=Numberofwindingsofthestringon

theaxleg=Accelerationduetogravityoftheenvironment.analizador_sintacticamente_oraciones_subordinadas_online.pdfh=Heightoftheweightassemblyfromtheground.r=Radiusoftheaxle.Nowwebegintocountthenumberofrotations,NuntiltheflywheelstopsandalsonotethedurationoftimetforNrotation.Thereforewecan

calculatetheaverageangularvelocityinradianspersecond.SinceweareassumingthatthetensionalfrictionWfisconstantovertimeandangularvelocityissimplytwicetheaverageangularvelocitySignuptoviewthefulldocument!lock_openSignUpUnformattedAttachmentPreviewExperimentNo.15Objective:Todeterminethemomentof

inertiaofaflywheel.Apparatus:Flywheel,weighthanger,slottedweights,stopwatch,metrescale.Theory:Theflywheelconsistsofaheavycirculardisc/massivewheelfittedwithastrongaxleprojectingoneitherside.Theaxleismountedonballbearingsontwofixedsupports.buildingandstructuralsurveyingn6notespdfThereisasmallpegon

theaxle.Oneendofacordislooselyloopedaroundthepeganditsotherendcarriestheweight-hanger.Let"m"bethemassoftheweighthangerandhangingrings(weightassembly).Whenthemass"m"descendsthroughaheight"h",thelossinpotentialenergyisTheresultinggainofkineticenergyintherotatingflywheelassembly(flywheeland

axle)isWhereI-momentofinertiaoftheflywheelassemblyω-angularvelocityattheinstanttheweightassemblytouchestheground.Thegainofkineticenergyinthedescendingweightassemblyis,Wherevisthevelocityattheinstanttheweightassemblytouchestheground.Theworkdoneinovercomingthefrictionofthebearingssupportingthe

flywheelassemblyisWheren-numberoftimesthecordiswrappedaroundtheaxleWf-workdonetoovercomethefrictionaltorq...PurchasedocumenttoseefullattachmentUsergeneratedcontentisuploadedbyusersforthepurposesoflearningandshouldbeusedfollowingStudypool'shonorcode&termsofservice.Studypool4.7Trustpilot4.5

Sitejabber4.4Stuckonahomeworkquestion?Ourverifiedtutorscananswerallquestions,frombasicmathtoadvancedrocketscience!MOMENTOFINTERTIAOFAFLYWHEEL.EGERTONUNIVERSITYFACULTYOFENGINEERINGANDTECHNOLOGYDEPARTMENTOFINDUSTRIALANDENERGYENGINEERIGCOURSE:B.Sc.

MANUFACTURINGENGINEERING.COURSETITLE:MACHINEELEMENTS11.COURSECODE:MENT223.TASK:MOMENTOFINERTIAOFAFLYWHEEL.

NAME:KIPROTICHGARISON.REGNO.

B13/14411/16.DATEOFSUBMISSION:…26/07/2018.SIGN:………………………INSTRUCTOR:ENGR.VINCENTODHIAMBO.MOMENTOFINTERTIAOFAFLYWHEEL.

MOMENTOFINERTIAOFFLYWHEELObjectiveTheobjectiveofthisexperimentistodeterminetherelationshipbetweentheangularaccelerationofflywheelandthetorqueproducingtheacceleration.TheoryConsideringafallingmass,Netforce=mg-FAcceleration=aHencema=mg-maF=m(g-a)Providedthataismuchgreaterthang.F=mgFor

thewheel,Angulardisplacementϴ=2[.zonagum.pdf

]WhereN=Numberofrevolutions.Averagevelocity=12(ϴ+ωN)[rads/s]TimeforNrevolution=tseconds.

Therefore,Angulardisplacementϴ=12ωNtandωN=athenceϴ=12at2fromwhicha=42Accordingtothesecondlawofmotion,torqueproducingacceleration=MOMENTOFINTERTIAOFAFLYWHEEL.Fr=C=K.

42FromwhichK=24TheconstantofproportionalityKiscalledthemomentofinertiaandmaybecalculatedfromthedimensionsandmassoftheflywheel.K=I=ρπ2°22WhereR=Radiusofflywheelw=Widthofflywheelρ=Densityoftheflywheel=7850kg/m3PARAMETERS:Diameterofdisc=250mmDiameterofshaft=25mmWidthofdisc

=50mmDensityofplate=7850kg/m3Procedure1.Taketheloadhangerandpullingcordandhooktheendloopoverthepegontheflywheelshaft.2.Windupadefinitenumberofturns,say8,fromthepositionwherethecordloopfallsoffthepeg.

3.rinnairur199inpartslistWindupthepullingcord8turnsandholdtheflywheelwithonehandandastopwatchwiththeother.Theengravedmarkshouldbebythepointeratthisstage.Releasetheflywheelandstartthewatch.whowanttobeamillionairequestionsandanswersCounttherevolutionswiththeaidofthemark,usingthistojudge

whentostopthewatchesthesetnumberofrevolutionsisturned.Theloadhangerwillfallontotheground.4.Repeattheaboveprocedureaddingloadsbyincrementof1Ν.literalequationsworksheetpdfKeeponrepeatingtheexperimentuntilatleastsixreadingshavebeenobtained.5.Tryretimingoneortwooftheloadstoseewhattheprobable

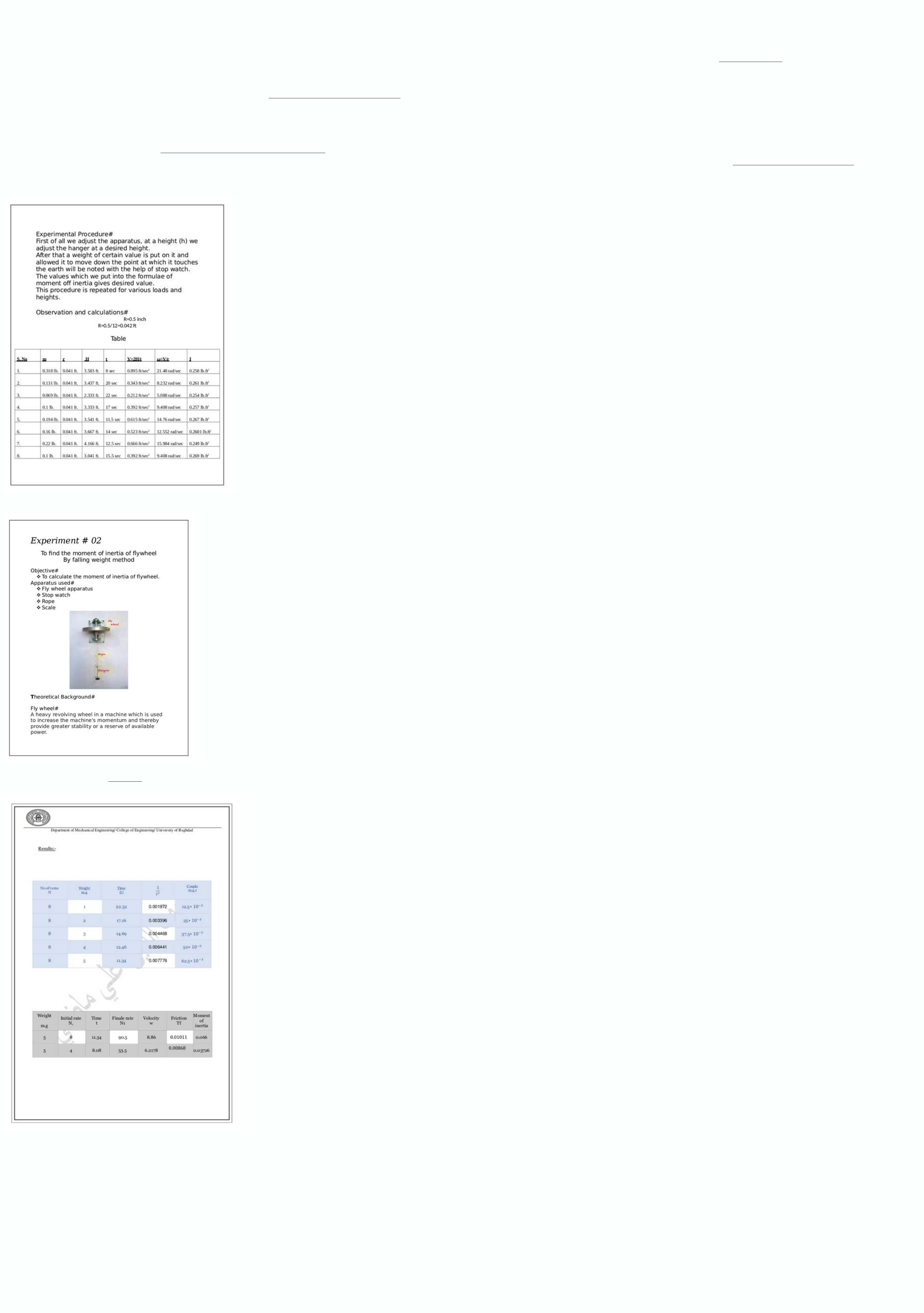

accuracyofthemeasurementis.let_it_snow_by_david_sedaris_reflection.pdfMOMENTOFINTERTIAOFAFLYWHEEL.DIAGRAMRESULTSTable1Accelerationofaflywheels/noNo.ofturnsΝWeight(mg)Time(t)s1/t²Effectivecouple(Nm)1.100.551.00.00038-0.13752.101.032.00.00098-0.01253.

101.525.00.001600.11254.diseñodeelementosdemaquinaspdfgratisparaen102.021.00.002270.23755.102.519.00.002770.36256.103.017.00.003460.48757.103.516.00.003910.6125MOMENTOFINTERTIAOFAFLYWHEEL.

GRAPHANALYSISCALCULATIONCALCULATIONOFEFFECTIVECOUPLE.Accordingtothegraph,y-intercept=-1.0591.0.05-1.5286=-1.4786*0.25=-0.36972.0.55-1.5286=0.9786*0.25=-0.24473.

1.55-1.5286=0.0214*0.25=0.005354.2.55-1.5286=1.044*0.25=0.25545.

3.55-1.5286=2.0214*0.25=0.50346.4.55-1.5286=3.044*0.25=0.75547.

5.55-1.8286=4.0214*0.25=1.0054Theoreticalcalculationofinertiaofflywheelisgivenby;K=I=ρπ2°22=7850*π*0.252*0.030*0.0252/2=0.01445MOMENTOFINTERTIAOFAFLYWHEEL.Sourcesoferrors1.Humanerrorsastheexperimentwashandledbyhumanmeasurementinsteadofmachines.2.Miscalculationandinaccuratecounting

ofthenumberofrotations.3.Highangularvelocityofthewheelrotation.4.Errorinrecordingthetimetakenforthedesirednumberofcompleterevolutions.5.Energylossbytheapparatustoenvironmentduetofrictionbetweentheflywheelcoreandthecord.ConclusionFromtheexperiment,themomentofinertiaofflywheelhadbeenstudiedin

whichtheresultsareinthedependencyofmassandradiusofthewheel.Theexperimentalvaluesofmomentofinertiaarefoundtohavehugedeviationsfromthetheoreticalone.Thehugedeviationisduetosourcesoferrorsandthedecreaseintheefficiencyratioofthemachineinthepracticalprocess.Weconcludedthattheerrorwasdoneby

humanmistakesandalsomightbebecauseofenergylossduetofriction.Thus,itisincomparablewiththetheoreticalonebecauseREFERENCES1.Egertonuniversity,industrialandenergyengineeringdepartmentlaboratorymanual.2.BevanT.1985"TheoryofMachines,"3rdEdition;CBSpublishers,Delhi,India.3.

Khurmi,R.2005"TheoryofMachines,"4thEdition,S.principleofaccountingkiesopdfChardpublishers,NewDelhi.4.leanmanufacturingemployeetrainingmanualpdffilepdfonlinepdfFerdBeerandRussJohnstone(2005)VectorMechanicsForEngineers;Statics,NewJersey,McGraw-Hill5.J.L.Meriam,L.G.Kraige(1998),Engineering

Mechanics:StaticSIVersion,NewYork,JohnWiley&SonsInc.6.R.A.Serway,R.22151677568.pdfJ.Beichner(2000),Physics:ForScientistsandEngineerswithModernPhysics,FifthEdition,Philadelphia,SaundersCollegePublishing7.AnthonyBedford,WallaceFowler,KennethM,Liechti,BedfordA.

(2003),Staticsandmechanicsofmaterials,UpperSaddleRiver,NewJersey,PrenticeHall.MOMENTOFINTERTIAOFAFLYWHEEL.