Public Assistance Debris

Monitoring Guide

March 2021

Table of Contents

i

Table of Contents

Table of Contents ........................................................................................................................................... i

Purpose ........................................................................................................................................................ iii

Executive Summary ...................................................................................................................................... iv

Chapter 1: General Eligibility Requirements ................................................................................................ 1

A. Eligible Debris Monitoring Work and Costs .................................................................................. 1

B. Reasonable Cost Guidance ............................................................................................................ 1

Chapter 2: Debris Monitoring Roles and Responsibilities ............................................................................ 3

A. Applicant’s Role and Responsibilities ........................................................................................... 3

B. Recipient’s Role and Responsibilities ............................................................................................ 3

C. FEMA Public Assistance Role and Responsibilities ....................................................................... 4

Chapter 3: Debris Monitoring Resources and Duties ................................................................................... 5

A. Force Account Resources .............................................................................................................. 5

B. Contractor Resources .................................................................................................................... 5

C. General Debris Monitor Qualifications ......................................................................................... 5

D. Types of Debris Monitors .............................................................................................................. 6

E. Reasonable Level of Effort Guidance ............................................................................................ 7

Chapter 4: Debris Monitoring Contract Provisions and Methods ............................................................... 9

A. General Procurement and Contract Oversight ............................................................................. 9

B. Basis of Payment ......................................................................................................................... 10

C. Duration of Contract ................................................................................................................... 11

D. Performance Measures and Termination Clause ....................................................................... 12

E. Conflict Resolution Process ......................................................................................................... 12

F. Types of Debris Removal Contracts ............................................................................................ 12

Chapter 5: Debris Monitoring by Debris Type ........................................................................................... 16

A. Vegetative Debris ........................................................................................................................ 16

B. Construction and Demolition Debris .......................................................................................... 16

C. Hazardous Waste ........................................................................................................................ 16

D. Household Hazardous Waste ...................................................................................................... 17

E. Electronic Waste ......................................................................................................................... 17

Table of Contents

ii

F. White Goods ............................................................................................................................... 18

G. Soil, Mud, and Sand .................................................................................................................... 18

H. Vehicles and Vessels ................................................................................................................... 19

I. Putrescent Debris ........................................................................................................................ 19

J. Infectious Waste ......................................................................................................................... 19

K. Chemical, Biological, Radiological, and Nuclear-Contaminated Debris ...................................... 20

Chapter 6: Documenting Eligible Work and Costs .................................................................................... 21

A. Documenting Force Account Debris Operation Costs ................................................................ 21

B. Documenting Contractor Debris Operation Costs ...................................................................... 21

C. Monitoring Reports ..................................................................................................................... 22

D. Electronic Load Tickets and Automated Reporting..................................................................... 22

Appendix A: Field Reference Guides ...............................................................................................................23

Appendix B: Sample Debris Monitoring Plan and Monitoring Forms ........................................................ 36

Appendix C: Monitoring Contract Process/Documents ............................................................................. 46

Purpose

iii

Purpose

When a disaster or emergency that generates large amounts of debris occurs, the Federal

Emergency Management Agency (FEMA), through its Public Assistance (PA) program, may

reimburse eligible PA Applicants, including State, local, tribal, and territorial (SLTT)

governments and certain Private Nonprofit (PNP) organizations, for costs associated with debris

removal operations.

This Debris Monitoring Guide provides PA Applicants and Recipients (States, Territories, or

Tribes that are the pass-through entity between the Applicant and FEMA) with guidance on

monitoring debris removal operations and eligibility requirements associated with necessary

work and reasonable costs to carry out a debris monitoring program.

Executive Summary

iv

Executive Summary

Effective coordination is required between the Applicant, the Recipient, and FEMA to ensure

that debris removal operations are efficient, effective, and eligible for FEMA PA grant funding.

Applicants must monitor their debris removal operations and document work and costs that may

be eligible for reimbursement through the PA grant program. Monitoring debris removal

operations requires observation and documentation of all work from the point of debris

collection to final disposal. This is to ensure that all work performed is in accordance with PA

guidelines and all applicable Federal and SLTT laws and regulations. Failure to properly monitor

debris removal operations may jeopardize PA funding.

In monitoring all aspects of its debris removal operations, including activities at all loading,

staging, and disposal sites, the Applicant can use its own staff (force account labor) or procure a

contract for these services. Applicants are required to use competitive contract bidding

procedures when procuring these services, unless circumstances only allow for a noncompetitive

method of procurement. Contracting out debris monitoring services does not absolve the

Applicant of their responsibility to supervise the performance of the contract. The Applicant

should provide clear direction, direct supervision, and a system of control and verification of the

performance of debris monitoring contract services. Overall, Applicants are strongly encouraged

to work with SLTT emergency management staff and FEMA to ensure compliance with the

provisions of the PA program.

While the Applicant has the primary responsibility for daily monitoring operations, the Recipient

is responsible for verifying that those monitoring activities are implemented. The primary role of

FEMA is to provide technical assistance and debris monitoring guidance to ensure that PA grant

requirements and eligibility criteria are met by the Applicant in all areas of the debris operation.

FEMA will evaluate the level of effort of debris monitoring operations for reasonableness when

determining the eligibility of debris monitoring costs. The level of effort for debris monitoring

operations should be proportionate with the magnitude of the disaster, the types and quantities of

debris to be removed, and the scope of the debris removal operation.

A good debris monitoring program should ensure accurate documentation of debris removal and

disposal operations and associated costs. This documentation serves as the basis for PA Project

Worksheets (PWs), which document work and costs eligible for reimbursement from FEMA.

Debris monitoring documentation is critical to verify that debris operations are eligible for

reimbursement, costs are reasonable, debris quantities are accurate, debris is tracked to its final

disposition, and all work and costs comply with regulatory requirements.

Pursuant to FEMA Directive 112-12, this guidance will have a review cycle of no greater than

three years. The FEMA PA Division will be responsible for any updates and changes to this

guidance.

Chapter 1: General Eligibility Requirements

1

Chapter 1: General Eligibility Requirements

In order for debris removal activities to be eligible for PA program funding, debris must be

generated by a Presidentially declared disaster; be located within the designated disaster area; be

the legal responsibility of an eligible Applicant to remove; and present an immediate threat to

life, improved property, or public health and safety. Applicants should consult FEMA’s Public

Assistance Program and Policy Guide

1

(PAPPG), which provides comprehensive information

regarding FEMA assistance and the requirements that Applicants must meet in order to receive

assistance for debris removal activities.

Eligible Debris Monitoring Work and Costs

The Applicant is responsible for monitoring debris operations to ensure that debris removal

activities claimed to the FEMA PA program for reimbursement are completed in accordance

with contract specifications and other supplemental guidance, PA program eligibility criteria,

and applicable Federal and SLTT laws, regulations and other requirements. FEMA PA personnel

will determine eligibility based on the defined scope of work (SOW) of the debris removal

operation, field observations, documentation, and reasonable costs. Eligible activities should be

clearly documented on loading tickets and the summary of debris totals.

Reasonable costs associated with the following debris monitoring activities may be eligible for

PA funding:

• Labor and material costs associated with debris monitoring staff such as field supervisors,

loading and tower/site monitors, and staff needed to complete documentation as

necessary to substantiate PA grant funding;

• Data compilation of load tickets and field debris monitoring reports to verify eligible

work and costs invoiced by the debris removal contractor (if under contract);

• Training of debris monitors on debris removal operations, debris monitoring and

documentation processes, and FEMA eligibility (FEMA can provide training to

Applicant debris monitors upon request); and/or

• Use of electronic load ticket system or automated debris monitoring system (ADMS) to

document debris quantities and eligibility. The Applicant should demonstrate through a

cost analysis that the use of the system is cost effective and the cost is reasonable.

Reasonable Cost Guidance

Costs associated with debris monitoring must be reasonable and necessary.

2

Competitively bid

debris monitoring contracts that comply with Federal and SLTT procurement regulations and

procedures will help to establish reasonableness for debris monitoring costs. Federal

procurement standards are found in Title 2 Part 200 of the Code of Federal Regulations.

3

1

Public Assistance Program and Policy Guide (PAPPG) Version 4 located at:

www.fema.gov/sites/default/files/2020-06/fema_public-assistance-program-and-policy-guide_v4_6-1-2020.pdf

2

2 Code of Federal Regulations (C.F.R.) Part 200, Subparts D and E.

3

2 C.F.R. §§ 200.317 - 200.327.

Chapter 1: General Eligibility Requirements

2

In determining if costs are reasonable, FEMA performs a preliminary review of the

documentation to assess the complexity of the project and expertise required to conduct the

work. Specific to debris monitoring, FEMA determines reasonableness

4

by evaluating:

• Labor: Are labor rates, labor classifications, and number of proposed labor hours

reasonable for the proposed SOW? The labor rates should be commensurate with the skill

level required by the job function. Professional engineers and those with similar

qualifications are not required to perform debris monitoring duties.

• Materials and Supplies: Are costs necessary and reasonable for the materials and

supplies, considering the type of work being performed.

• Profit: Was profit negotiated as a separate element of the contract price?

5

Project Management and Design Services

Costs which are considered project management and/or design services

6

differ from eligible

debris monitoring costs. Project management and design services are expenses for the initial

design and oversight of work performed related to an eligible project from the design phase

(when necessary) to the completion of work. These costs should be documented and claimed

separately. The eligibility of this work and its cost will be evaluated on a case-by-case basis.

Such project management and/or design services may include costs associated with direct

management and oversight of the debris removal operation by an Applicant’s force account labor

or by a consulting firm retained to analyze, design, and oversee the debris removal operation.

These costs may also include labor costs associated with project management services for the

debris removal operation, developing reports to establish contractor performance measures, and

evaluating operational efficiency. These costs are separate and distinct from costs related to

management and administration of PA awards and subawards.

7

4

Chapter 6:I.A. Reasonable Cost Analysis of the PAPPG (V4).

5

2 C.F.R. § 200.323(b).

6

Chapter 6:XV. Project Management and Design Services of the PAPPG (V4).

7

Chapter 6:XVI. Grant Management and Administration of the PAPPG (V4).

Chapter 2: Debris Monitoring Roles and Responsibilities

3

Chapter 2: Debris Monitoring Roles and Responsibilities

The Applicant has the primary responsibility for monitoring its debris removal operations. The

Recipient, as a pass-through entity, is responsible for ensuring that Applicants comply with grant

conditions and monitoring the activities of the Applicant. FEMA provides guidance and

technical assistance and makes final eligibility determinations related to debris-related work and

costs.

Applicant’s Role and Responsibilities

Applicants are required to maintain oversight to ensure that contractors perform in accordance

with the terms, conditions, and specifications of their contracts or purchase orders.

8

Debris

monitors serve as the Applicant’s field representatives. They ensure that the terms and specific

monitoring and documentation requirements of debris removal contracts are adhered to and met.

Having a debris monitor does not relieve Applicants of the obligation to maintain oversight over

both the debris monitoring and debris removal costs.

FEMA recommends that Applicants clearly outline their debris monitoring requirements in their

debris management plan, requests for proposals (RFPs), and debris removal contracts. These

documents should include instructions on actions the Applicant needs to take to document and

correct non-compliance issues. If an Applicant undertakes work that is ineligible for FEMA

funding, a methodology should also be established to separate ineligible work from eligible

work. Optimally, this methodology should be discussed with the Recipient and FEMA prior to

implementation to ascertain compliance. Refer to Appendix B: Sample Debris Monitoring Plan

and Monitoring Forms for a sample debris monitoring plan, including monitoring forms and refer

to Appendix C: Monitoring Contract Process/Documents for Contract documents.

Recipient’s Role and Responsibilities

While the Applicant has the primary responsibility for daily monitoring operations, the Recipient

is responsible for verifying that those monitoring activities are implemented. As Recipient, the

State or Tribe are the pass-through entity between the Applicant and FEMA. The Recipient

should ensure that the Applicant is complying with all grant requirements and is performing

adequate monitoring. The Recipient may conduct random monitoring at loading and disposal

sites to ensure compliance with PA grant requirements. Refer to Appendix A: Field Reference

Guides for more information.

8

2 C.F.R. § 200.318(b).

Chapter 2: Debris Monitoring Roles and Responsibilities

4

FEMA Public Assistance Role and Responsibilities

The primary role of FEMA is to provide technical and debris monitoring guidance to ensure that

PA grant requirements and work and costs in all areas of the debris operation meet PA eligibility

criteria. FEMA may also conduct random, periodic checks of debris loading, staging, reduction,

and disposal sites. FEMA is responsible for:

• Determining whether the debris removal activities are eligible;

• Verifying compliance with all environmental and historic preservation laws and

executive orders; and

• Reporting any noncompliance, misconduct, or other issues for resolution with the

Recipient and Applicant.

In disasters where the estimated amount of debris is 200,000 cubic yards (CY) or greater, the

Federal Coordinating Officer (FCO) may provide technical expertise and advise to the Recipient

or Applicant on debris monitoring through a mission assignment with the U.S. Army Corps of

Engineers (USACE).

FEMA does not direct field operations on behalf of the Applicant. FEMA is not a party to the

Applicants contract and will not resolve disputes. The Applicant is responsible for implementing

and managing its debris removal and monitoring activities. Refer to Appendix A: Field

Reference Guides for additional information.

Chapter 3: Debris Monitoring Resources and Duties

5

Chapter 3: Debris Monitoring Resources and Duties

Force Account Resources

Applicants are encouraged to use their own employees (force account labor) to monitor debris

removal operations.

9

An Applicant’s own employees are the most familiar with the jurisdiction

and know the priorities of the Applicant’s debris management plan.

Other benefits of using force account labor for debris monitoring include:

• The local workforce may be able to respond immediately after the disaster.

• Standard timesheet and equipment documentation procedures are typically adequate for

documentation purposes.

Contractor Resources

An Applicant may hire contractors to provide debris monitoring services. Debris monitoring

contractors should not be employed by or affiliated with the debris removal contractor.

Applicants are required to use competitive contract bidding procedures when procuring these

services, unless they can justify sole sourcing.

10

If the Applicant, in compliance with SLTT law,

wants to issue a sole source contract rather than conduct a sealed bidding process, the Applicant

would have to demonstrate that there are “exigent circumstances” necessitating procurement by

non-competitive methods and use of a sealed bidding process would cause an unacceptable

delay. Applicants are also required to maintain proper oversight of these contracts to ensure

compliance with contract terms.

11

The Applicant must include in the contract a termination date

for the non-competitively procured contract and justify in writing why the period of performance

is reasonable under the prevailing circumstances.

12

More information on debris monitoring

contracts is found in Chapter 4: Debris Monitoring Contract Provisions and Methods.

General Debris Monitor Qualifications

Applicant debris monitors should:

• Fully understand their responsibilities in accordance with the terms of the debris removal

contract and other specific guidance provided by the Applicant;

• Possess the capability to estimate debris quantities accurately and objectively;

• Understand all phases of debris management operations, including loading sites, debris

management sites (DMSs), and final disposition locations;

• Be able to differentiate between debris types;

• Be able to complete load tickets properly;

• Understand site safety procedures;

• Communicate effectively and efficiently; and

• Possess previous construction site experience (preferred).

9

44 C.F.R. § 206.228.

10

2 C.F.R. § 200.320(f) or analogous state obligations if procurement under 2 C.F.R. § 200.317 auspices.

11

2 C.F.R. § 200.318(b).

12

See generally 2 C.F.R. § 200.320(f).

Chapter 3: Debris Monitoring Resources and Duties

6

• Have general knowledge pertaining to the operation of large construction machinery

(preferred).

Debris monitors do not need to be registered professional engineers.

In addition to the general qualifications for debris monitors, field supervisors need to:

• Possess the ability to communicate with field staff as well as management;

• Be able to resolve conflicts and issues in the field; and

• Understand when to elevate issues to the Applicant’s management.

Types of Debris Monitors

Applicants need to monitor all aspects of the debris removal operation, including activities at all

loading, staging, and disposal sites. Debris monitors may have different roles and responsibilities

at different stages or components of a debris removal operation; an individual may assume the

role of each monitor type at various stages of the disaster. Debris monitors report directly to the

field supervisor regarding their daily oversight. All logs and load tickets are submitted daily to

the field supervisor. See Appendix A: Field Reference Guides for lists of debris monitoring

duties by type of debris monitor.

Loading Site Monitors

Loading site monitors perform on-site, street-level debris monitoring at all loading sites to verify

debris eligibility based on contract requirements, and initiate debris removal documentation

using load tickets. Loading site debris monitors’ primary duties are:

• Estimating load volumes and issuing load tickets at the load sites, retaining a copy of the

ticket (for detailed description of load ticket chain-of-custody, refer to Appendix B:

Sample Debris Monitoring Plan and Monitoring Forms); and

• Maintaining logs of daily subcontractor performance, eligibility, or other activities as

required.

• Can be a roving monitor who follows a truck around throughout the day or checks-in on

multiple loading trucks. Produces roving monitor report.

Tower/Site Monitors

Debris monitors at a DMS are often referred to as “tower” or “site” monitors.” Tower/site

monitors’ primary duties are:

• Accurately measuring and documenting load hauling compartments prior to debris

hauling operations (and recertifying on regular basis);

• Collecting and physically controlling load tickets;

• Ensuring that all debris is removed from trucks at DMSs;

• Monitoring DMS development and restoration; and

• Overseeing debris reduction (grinding, burning, chipping, etc.).

Chapter 3: Debris Monitoring Resources and Duties

7

Field Supervisor

The Applicant’s field supervisor resolves field operational, eligibility, and safety issues, and

communicates these issues to the Applicant. They may also coordinate daily activities with

FEMA, the Recipient, and Applicant field personnel. The field supervisors’ primary duties are:

• Scheduling and deploying the loading and tower/site debris monitors and overseeing their

daily activities at loading sites and disposal and staging sites;

• Conducting or overseeing truck certifications, load measurements, and photo-

documentation as required; and

• Collecting daily logs from the debris monitors and tabulating truck load data for the daily

report.

Reasonable Level of Effort Guidance

All costs must be associated with a reasonable level of effort, including appropriate numbers of

debris monitoring personnel and clerical staff related to the scope of the debris removal

operation. FEMA will evaluate the level of effort of debris monitoring operations for

reasonableness when determining the eligibility of debris monitoring costs. The level of effort

for debris monitoring operations should be proportionate with the magnitude of the disaster, the

types and quantities of debris to be removed, and the scope of the debris removal operation.

Historical data for debris monitoring operations suggests the following level of effort may be

appropriate for field efforts.

Level of Effort for Debris Loading Sites

• Rural areas: One loading monitor may be provided for each loading device/location in

order to properly observe all debris loading activity. The number of loading monitors can

be amended to allow one monitor to oversee two or three contractor loading sites, if the

loading activity can be properly observed from a single controlled location and the

collected debris can be documented and verified as eligible or ineligible.

• Urbanized or higher-density areas: One loading monitor may be provided for each

loading site. One loading monitor may be provided for every three to four loading sites if

the loading monitor can monitor the sites via line-of-sight or a controlled access point.

Level of Effort for Debris Management Sites

• Tower/site monitors: Tower/site monitors are required at DMSs regardless of if the site

is a temporary or a permanent one. Depending on the set-up of the DMS, a minimum of

one tower/site monitor is required to document load quantities and verify that trucks are

emptied. Additional tower/site monitors may be needed at exit locations to verify that

trucks are emptied, or at reduction (grinding burning, chipping, etc.) locations to

document and verify production rates.

• Field supervisors: If multiple DMSs are in operation, one field supervisor may be added

for every 10 debris load site monitors, or as needed for exceptionally large and unique

operations to ensure adequate management of operations.

• Clerical/data entry support: Typically, one or two data entry personnel can

accommodate the daily data amassed when debris operations use load tickets for

Chapter 3: Debris Monitoring Resources and Duties

8

documentation. Larger or faster operations with a multitude of reports may require

additional clerical support. The number of clerical/data entry personnel should be

adjusted to the needs of the Applicant. The use of automated debris monitoring

documentation systems may significantly reduce the required level of effort for data entry

support.

Chapter 4: Debris Monitoring Contract Provisions and Methods

9

Chapter 4: Debris Monitoring Contract Provisions and Methods

When procuring contracts for debris removal operations and monitoring services, Applicants

must use their standard procurement processes and practices that conform to SLTT procurement

policies and regulations, as well as those required by Federal regulations.

13

Failure to adequately

follow procurement requirements may result in the deobligation of all or some of an Applicant’s

PA funding. If a Federal requirement is different than the SLTT requirements, or the Applicant’s

own requirements, it must use the more restrictive requirement.

14

Applicants are strongly encouraged to work with SLTT emergency management staff and FEMA

to ensure compliance with the provisions of the PA program, as well as other applicable statutes

and regulations, if they intend to seek PA grant funding. Upon request, FEMA PA program

personnel will review an Applicant’s procurement process to highlight potential instances of

non-compliance with the federal procurement rules.

15

FEMA can also provide high-level reviews

of contracts to highlight potential instances of non-compliance with the federal procurement

rules.

General Procurement and Contract Oversight

Applicants are strongly encouraged to consider, and/or comply with, the following guidance

when procuring and overseeing contracts for debris monitoring services:

Procurement Process

• Use competitive bidding procedures to meet procurement requirements for Federal

grants.

16

• Use abbreviated emergency procurement procedures that include an expedited

competitive bid process only if time does not allow for more stringent procedures and if

they are allowed under SLTT and Federal laws, codes, or ordinances.

• Maintain records regarding the history of the procurement

17

and document procedures

used to obtain/award contracts (procurement information, bid requests, and tabulations,

etc.).

• Seek legal review of the contract from Applicant’s legal counsel and the process used to

procure it, to ensure compliance with all applicable Federal and SLTT requirements.

Scope of Work

• Verify that all requests for proposals, bids, and contracts have a well-defined SOW,

specified costs, basis of payment, performance schedule, and descriptions of the type of

service provided by each labor category and skill class.

13

2 C.F.R. § 200.318(a).

14

Chapter 6:VIII.B. Procurement and Contracting Requirements for Tribal and Local Government Agencies and

Private Nonprofits of the PAPPG (V4).

15

2 C.F.R. §§ 200.317 - 200.327.

16

2 C.F.R. § 200.319.

17

2 C.F.R. § 200.318(i).

Chapter 4: Debris Monitoring Contract Provisions and Methods

10

• Ensure that labor rates are commensurate with the skill level required by the debris

monitoring job function. Professional engineers and other similar qualifications are not

required to perform monitoring duties.

• Use a load ticket system (paper or electronic) to record with specificity where debris is

picked up (e.g., street address) and the amount picked up, hauled, reduced, and disposed

of.

• Ensure that the level of effort provided by the monitoring contractor and the contract

terms is reasonable.

Reasonable Costs

• Ensure that debris monitoring contract costs are reasonable and necessary.

18

Competitively bid contracts that comply with Federal and SLTT procurement regulations

and procedures will help to establish reasonable costs for the work.

• The Applicant must perform a price/cost analysis for all contractors or contract

modifications over the simplified acquisition threshold currently set at $250,000.

19

Additionally, profit must be negotiated as a separate element when performing a cost

analysis and for each contract when there is no price competition.

20

Contract Requirements

• Award contracts to responsible bidders who are reputable and qualified contractors.

o Conduct reference checks on contractors’ performance history with the State’s

contractor licensing board and with previous clients before awarding contracts.

o Verify that potential contractors are not on a State’s “Debarred Contractor” listing.

21

o Check SAM.gov to verify that potential contractors have not been suspended or

debarred from performing work funded by the federal government.

• Require the contractor to provide a safe working environment, including properly

constructed monitoring towers.

• Ensure that complete and accurate records are kept of contractor activities and costs to

include in reimbursement requests.

Basis of Payment

The basis of payment and the payment process must be clearly outlined in the contract.

Contractor payments should be based upon verification of completed work, and the required

information for the payment request should be included within the provisions of the contract.

The SOW and costs for the service are key factors in analyzing reasonable costs. When

determining if a cost for debris monitoring is reasonable, FEMA considers the level of effort

required for the monitoring services, supervision, and support services to perform the job

requirements effectively and efficiently. Debris monitoring services should be tailored to the

scale of the debris operations, the schedule requirements, and the Applicant’s overall concept of

18

2 C.F.R. Part 200, subpart E.

19

The simplified acquisition threshold is set by the Federal Acquisition Regulation at 48 C.F.R. § 2.101. The

threshold is adjusted periodically for inflation.

20

2 C.F.R. § 200.324(b).

21

2 C.F.R § 200.318(h).

Chapter 4: Debris Monitoring Contract Provisions and Methods

11

operations. This includes planning for the number of DMSs and final disposition sites,

acceptable travel distances, truck routes, neighborhood safety issues, personnel planning, and

documentation requirements.

The debris monitoring contract must include the applicable contract provisions addressing

payment, contract duration, performance measures, termination for convenience, termination for

cause, and a conflict resolution process, and any other required contract provisions.

22

The

Applicant should:

• Consider using a progress payment method for contract services. This method requires

specific documentation from the contractor to verify and validate the completed work and

support the contractor’s invoices.

• Provide supervision and oversight of the debris monitoring operations to ensure that only

approved and necessary hours are applied to the debris monitoring contract. Applicants

are required to maintain contractor oversight to ensure that contractors perform in

accordance with the terms, conditions, and specifications of their contracts or purchase

orders.

23

• Confer with the contractor to determine the deployment of monitors, daily schedules, and

the number of personnel, supervisors, and clerical/data support assigned at any given

time.

Generally, documentation for debris monitoring reimbursement includes:

• Personnel assignments, duties, and responsibilities

• Timesheets

• Debris monitoring reports

• Debris totals (CY and tonnage)

• DMS reports

• Exception reports (when debris monitoring reveals problems with debris operations)

• Truck/Trailer Certification reports

• Geographic information system (GIS) planning and progress reports

• Debris progress reports

• Safety reports

Duration of Contract

Debris removal and monitoring services contracts should include specific timelines for work to

be completed. The contract should clearly state the duration and the scheduled milestones. By

doing so, the Applicant sets clear expectations for the contractor. Moreover, the contractor can

effectively manage resources and schedule work to meet the Applicant’s requirements. The

Applicant should determine the contractor’s mobilization requirements (e.g., whether debris

monitors are required during the debris clearance phase).

22

2 C.F.R. § 200.327.

23

2 C.F.R. § 200.318(b).

Chapter 4: Debris Monitoring Contract Provisions and Methods

12

Performance Measures and Termination Clause

The contract should include performance measures that specify how performance will be

evaluated and measured, including the size and number of monitoring crews, the number of

truckloads monitored each day by the monitoring crews, the number of truckloads arriving at

each DMS or final disposition site, the processing rate for a reduction site, and the number of

monitoring crews in relation to the debris removal crews. Additionally, all contracts in excess of

$10,000 must address termination for cause and for convenience by the non-Federal entity,

including the manner by which termination will be effected and the basis for settlement. This

clause should describe probable reasons for termination.

Conflict Resolution Process

The conflict resolution process should be well defined in the contract. The process should

include alternatives for mediation in case an issue proves difficult to resolve. Contracts in excess

of $250,000 must include a remedies clause that addresses administrative, contractual, or legal

remedies in instances where contractors violate or breach contract terms and provide for such

sanctions and penalties as appropriate.

24

Types of Debris Removal Contracts

There are several types of debris removal contracts and each type of debris removal contract has

variables that can dictate adaptations to the necessary debris monitoring activities to protect the

Applicant’s interests. The different types of contracts, specific contract provisions, monitoring

efforts, and documentation requirements are described in this discussion and summarized in

Table 1 at the end of Section 6. The most common types of debris removal contracts are unit

price, lump-sum, and time-and-materials (refer to Appendix A: Field Reference Guides).

Unit Price

Unit price contracts are used when the individual work tasks are known, but the total amount of

work cannot be known in advance. Units of work can be measured in terms of weight, volume,

or any other quantifiable measure (Figure 1). The contractor uses estimated quantities to

establish a total contract price.

24

2 C.F.R. § 200.327.

Chapter 4: Debris Monitoring Contract Provisions and Methods

13

Since a unit price contract is initiated

based on an estimate of debris quantities,

documentation of the location, eligibility,

and quantities of debris (CY or tonnage)

during the debris processing is essential.

• Debris monitoring is essential

during pick up, transportation,

eligibility determination,

segregation, staging, reduction,

and final disposition.

• The Applicant should manage the

measurement of the trucks/trailers

used to haul the debris. The

volume of each truck should be

measured and certified before

being allowed into service.

Lump-Sum

Lump-sum contracts are used when the SOW can be identified and quantified. Bid requests for

lump-sum contracts include a set of specifications that have a well-defined SOW for a finite

amount of time.

The advantage of a lump-sum contract is that the total price for the specified work is known at

the time the contract is awarded. For example, 250 tons of mulched debris hauled from 1000 N.

Debris Road to the county landfill at 3450 S. Main Street will equal $XX,XXX.

Loading monitors are required to validate that only contract-identified debris is collected. These

quantities should match the quantities identified in the debris removal contract.

• The DMS site/tower monitors should carefully review the processing of materials,

especially the quantities of materials collected for processing (grinding, burning,

chipping, etc.), and the quantities at the back end of the processing.

• Documentation of truckloads and debris volumes are still needed if the final tally of

debris quantities vary significantly from the original contract estimates; change orders

may be necessary to adjust the contract price. This documentation is essential to

establish final debris volumes.

• When applicable, the debris quantities entering a DMS should be compared with the

debris quantities that have been processed. For example, chip piles or outbound

truckloads can be measured to corroborate the debris volumes.

Time-and-Materials

A time-and-materials contract establishes hourly rates for labor and equipment that will be used

to perform specific tasks. For example, backhoe with loader, X CY bucket, and operator =

$XX/hour. The contractor is paid based on the sum of the actual cost of materials and the direct

Figure 1: Debris Monitors Determine Type and Quantity

of Debris

Chapter 4: Debris Monitoring Contract Provisions and Methods

14

labor hours charged at a fixed hourly rate that reflect

wages, general and administrative expense, and

profit.

25

Applicants should work closely with the SLTT and

FEMA when awarding such contracts to ensure PA

eligibility requirements are met. The following

requirements apply to time-and-materials contracts and

must be memorialized:

• Use only after determining that no other

contract type is suitable;

• Time-and-materials contract must contain a

not-to-exceed clause;

26

• The contract must include a ceiling price which the contractor exceeds at its own risk;

• The Applicant must maintain a high degree of contractor oversight to avoid any

unnecessary cost overruns; and

• Once the scope of work becomes clear, the Applicant must transition to a more suitable

contract type.

A higher level of monitoring of time-and-materials contracts is required. Debris monitors should

produce daily inspection reports that clearly quantify the amount of work accomplished each

day, including:

• The number of hours worked (scheduled work hours/crew size).

• The type and quantity of each type of truck/trailer/equipment used (Figure 2).

• Verification of equipment hours. Only active work hours should be submitted for FEMA

reimbursement.

• Standby time is not eligible for FEMA reimbursement.

• Verification of labor hours as compared to equipment hours. Intermittent use of

equipment may result in a crew having more equipment hours than labor hours; this type

of discrepancy needs to be verified by the debris monitors.

• The weather conditions as they affect daily work.

• Production rates for each staging and reduction site.

• Quantities of debris hauled (CY or per ton). If debris is hauled based on CY, load tickets

may be used as a way of checking contractor efficiency.

25

2 C.F.R. § 200.318(j)(1).

26

2 C.F.R. § 200.318(j).

Figure 2: Type and Duration of

Equipment Used Must Be Documented

Chapter 4: Debris Monitoring Contract Provisions and Methods

15

Table 1 outlines the monitoring requirements for each type of contract.

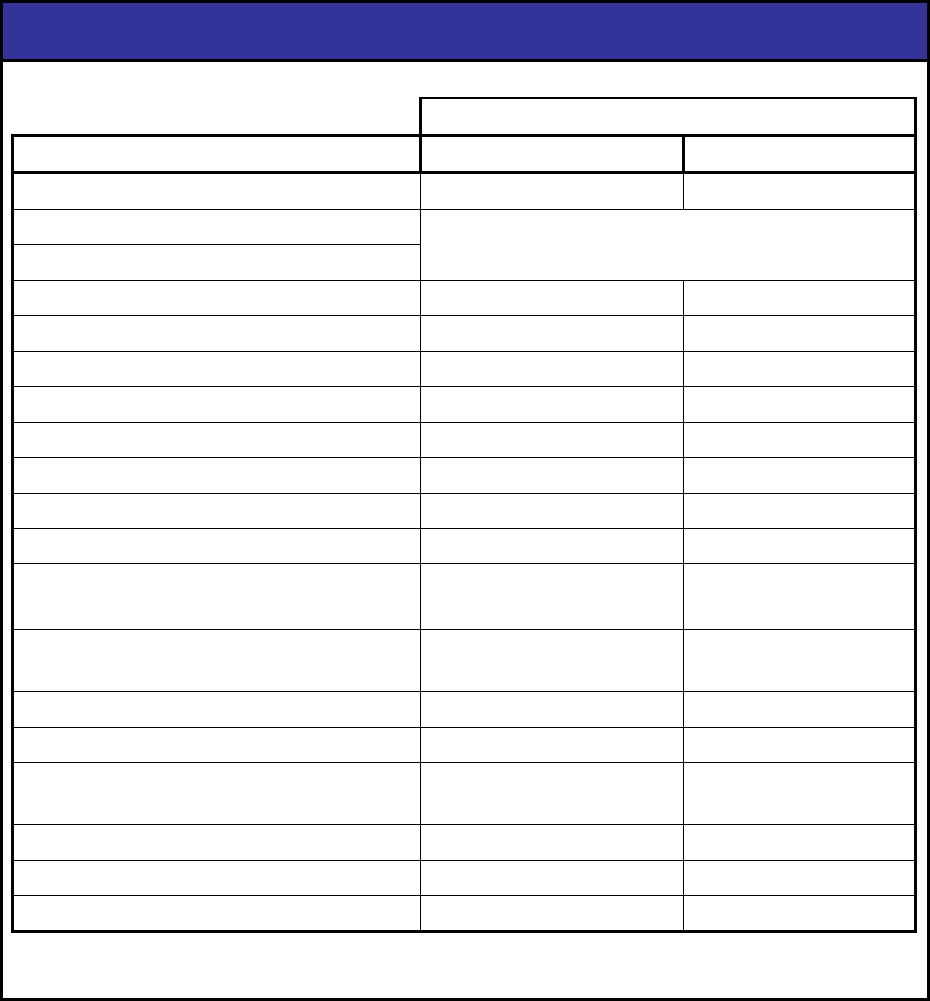

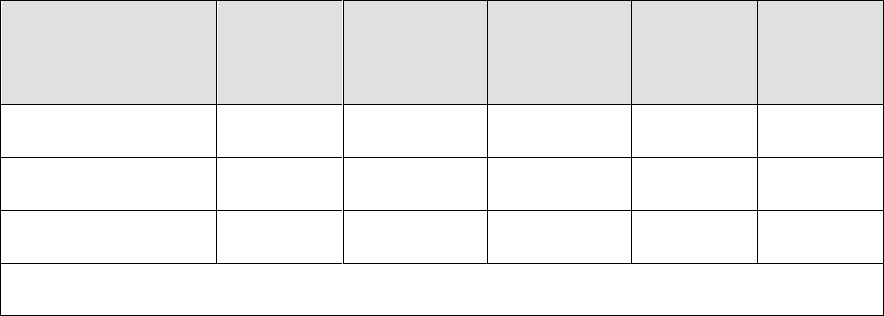

Table 1: Monitoring Requirements by Contract Type

Contract

Type

Scope of Work

Monitoring Required

Comments

Crew Efficiency

Collection Site

DMSs

Disposal Site

Compliance

Lump-

Sum

Defined debris

quantities and

reasonable costs.

Estimate is basis

for contract

costs.

• Assess debris eligibility at

collection site

• Quantities are required to

determine reasonable costs

and establish change orders

• Ensure ONLY debris from

within contract limits is

processed

Unit Price

– CY

Based on eligible

debris listed on

load tickets.

• Assess debris eligibility at

collection site

• Document debris quantities

• Verify debris processing

volumes

Unit Price

– Ton

Based on actual

weight

measurements of

eligible debris

listed on load

tickets.

• Assess debris eligibility at

collection site

• Document debris quantities

• Verify debris processing

weights

• Verify calibration of scales

Time-and-

Materials

Based on labor,

equipment, and

materials records.

Reasonable costs

evaluated by

determining costs

per unit.

• Assess debris eligibility at

collection site

• Typically used for road

clearance activities during

the Response Phase

• Supervising and monitoring

every work crew is required

• Tracking debris removal

quantities is still required to

determine reasonable costs

Chapter 5: Debris Monitoring by Debris Type

16

Chapter 5: Debris Monitoring by Debris Type

Debris monitoring considerations and responsibilities may vary depending on the type of debris

being removed. Debris monitoring considerations for each of the primary debris types are

described below. Refer to Appendix A: Field Reference Guides for additional debris monitoring

recommendations.

Vegetative Debris

Vegetative debris may consist of whole trees, tree stumps, tree branches, tree trunks, and other

leafy material. Depending on the size of the debris, the collection of vegetative debris may

require the use of flatbed trucks, dump trucks, and grapple loaders. For consideration:

• Hand-loaded trucks/trailers are graded at 50

percent of a load because of the low

compaction achieved by hand-loading.

27

• This type of debris may be recyclable or have

salvage value. Document separation and

salvage operations when implemented.

• For special vegetative debris considerations,

refer to the PAPPG.

28

Construction and Demolition Debris

Construction and demolition (C&D) debris can be

defined as damaged components of buildings and

structures, such as lumber and wood, gypsum

wallboard, glass, metal, roofing material, tile,

carpeting and floor coverings, window coverings, pipe, concrete,

29

fully cured asphalt,

equipment, furnishings, and fixtures. The definition of C&D debris may vary between

jurisdictions and what is included in one jurisdiction may be excluded in another. When

monitoring, consider that the C&D debris must be disaster-generated (i.e., eligible C&D debris

cannot be the result of an Applicant’s rebuilding efforts) and must present an immediate threat to

be considered for FEMA eligibility.

Hazardous Waste

The Applicant must comply with Federal and SLTT environmental requirements for handling

hazardous waste. Acceptable FEMA reimbursable activities related to hazardous materials are

described in the PAPPG.

30

Hazardous waste is regulated under the Resource Conservation and

Recovery Act (RCRA) and contains properties that make it potentially harmful to human health

or the environment. In regulatory terms, a RCRA hazardous waste is a waste that appears on one

of the four hazardous waste lists

31

or exhibits at least one of the following four characteristics:

27

Chapter 7:I.E.3. Hand-Loaded Trucks and Trailers of the PAPPG (V4).

28

Chapter 7:I.B. Hazardous Limbs, Trees, and Stumps of the PAPPG (V4).

29

Chapter 7:II.U.4. Ineligible Work of the PAPPG (V4).

30

Chapter 7:II.K. Hazardous Materials of the PAPPG (V4).

31

40 C.F.R. Part 261.

Figure 3: Hand-Loaded Truck

Chapter 5: Debris Monitoring by Debris Type

17

• Ignitability

• Corrosivity

• Reactivity

• Toxicity

When monitoring, consider:

• Hazardous wastes may require segregation and

special handling (Figure 4).

• Improper segregation of the hazardous waste

debris should be documented.

• If unsafe practices are observed during the

handling and disposal of hazardous materials, the

appropriate authorities should be notified.

• Safety precautions will vary depending upon the

circumstances and type of hazardous materials

encountered, but they may include personal

protective equipment, decontamination stations,

closed and secured containers, and covered trucks

or specialized containers.

• Monitor hazardous material processing carefully

and regularly to verify that proper precautions are

taken and that the chain-of-custody is maintained.

• Verify that hazardous materials are delivered to

an appropriate DMS since hazardous wastes

typically require special handling, transportation,

and final disposition that are significantly more

costly than typical waste disposal.

Household Hazardous Waste

Household Hazardous Waste (HHW) refers to hazardous products and materials that are used

and disposed of by residential consumers, rather than commercial or industrial consumers. HHW

include, but are not limited to, some paints, stains, varnishes, solvents, pesticides, and other

products or materials containing volatile chemicals that catch fire, react, or explode under certain

circumstances, or that are corrosive or toxic. When monitoring:

• Verify and document that HHW is picked up and handled by specialists licensed by the

Recipient’s Department of Environmental Quality (DEQ) and managed in designated

areas within the DMS.

• Verify and document that the chain-of-custody is maintained throughout the collection,

handling, transport, and disposal of HHW.

Electronic Waste

Electronic waste (e-waste) refers to electronics that contain hazardous materials, such as cathode

ray tubes. Examples of e-waste include, but are not limited to, computer monitors and

Figure 4: Segregation of Hazardous Debris

Chapter 5: Debris Monitoring by Debris Type

18

televisions.

32

Typically, these products contain minerals and chemicals that require specific

disposal methods. When monitoring ensure that:

• E-waste is removed intact, collected, and stored at the DMS for later processing;

• E-waste complies with state e-waste requirements where applicable;

• Separation and salvage activities are implemented and documented as this type of debris

may be recyclable or have salvage value; and

• E-waste is segregated (in wildfire events, white goods and E-waste may not be able to be

segregated and therefore should be documented as one).

White Goods

White goods are defined as discarded household appliances such as refrigerators, freezers, air

conditioners, heat pumps, ovens, ranges, washing machines, clothes dryers, and water heaters.

Many white goods contain ozone-depleting refrigerants, mercury, or compressor oils that must

be removed and processed following environmental protocols and procedures before the white

goods can be further processed for disposal and recycling. When monitoring:

• Document that white goods are collected separately, cleaned, and processed to remove

putrescent debris inside and to remove all

oils, solvents, and refrigerants (Figure 5).

• If white goods are to be collected without

being cleaned, verify and document that the

DMS includes ample space for processing

the collected white goods.

• This type of debris may be recyclable or

have salvage value. Document separation

and salvage activities that are implemented.

Soil, Mud, and Sand

Floods, landslides, winds, wildfires, and storm

surges often result in soil, mud, and sand debris on improved public property and public rights-

of-way. Facilities commonly affected by this type of debris include streets, sidewalks, storm and

sanitary sewers, water treatment facilities, drainage canals and basins, parks, and public

swimming pools. When monitoring:

• Document that only the disaster-generated silt and soils are removed. This requires an

understanding of pre-disaster conditions as well as the documented maintenance of the

affected area.

• Contaminated soils may require special handling depending on the contaminant.

Document any contaminated soil issues to ensure proper handling, processing, and

disposition.

• Verify that any contaminated disaster-generated soils are addressed by specialists from

the State’s DEQ and/or U.S. Department of Environmental Protection (EPA) and

managed appropriately in designated areas.

32

40 C.F.R. Part 261.

Figure 5: White Goods Being Staged

Chapter 5: Debris Monitoring by Debris Type

19

Vehicles and Vessels

Vehicles and vessels may be damaged, destroyed,

displaced, or lost as a result of a disaster (Figure 6).

These vehicles and vessels may eventually be

abandoned because of the damage incurred or

because the original owners have relocated.

Vehicles and vessels may be classified as debris if

they block public access and critical facilities and

are abandoned.

33

When monitoring:

• Verify that each vehicle or vessel

identification number is documented and

processed appropriately according to

applicable municipal, state, or coastal law.

• Verify that collected vehicles and vessels are

transported to a collection area where they are secured and protected. Depending on the

ownership, the vehicles or vessels can be returned, salvaged, or destroyed.

• Verify that all vehicles and vessels have all minerals and fluids removed before

processing or destruction.

• This type of debris may be recyclable or have salvage value. Document separation and

salvage activities that are implemented.

Putrescent Debris

Putrescent debris is any debris that will decompose or rot, such as animal carcasses and other

fleshy organic matter. Handling of putrescent debris must comply with applicable Federal and

SLTT requirements. When monitoring:

• Document that putrescent debris is collected in accordance with contract specifications or

other specific requirements.

• Document the volume of putrescent debris. The volume of putrescent materials cannot be

determined based solely on the volume of the originally inventoried materials because the

spoiled materials may have lost a significant portion of their volume. The actual volume

at the time of removal needs to be documented.

Infectious Waste

Infectious waste is waste capable of causing infections in humans and can include contaminated

animal waste, human blood and blood products, medical waste, pathological waste, and

discarded sharps (needles, scalpels, or broken medical instruments). Clearance, removal, and

disposal of infectious waste may be under the authority of another Federal agency (the Centers

for Disease Control and Prevention, EPA, etc.) or applicable state agency. Upon review of

applicable Federal statutes, regulations, and policies governing infectious waste, FEMA will

determine eligibility on a case-by-case basis. When monitoring:

33

Chapter 7:I.D. Privately Owned Vehicles and Vessels on Public Property of the PAPPG (V4).

Figure 6: Boat and Vessel Debris

Chapter 5: Debris Monitoring by Debris Type

20

• Document that the disaster-related infectious waste is collected and separated in

accordance with prescribed safety and medical practices. SLTT or Federal health officials

may dictate the collection process, including collection containers, protective gear,

decontamination requirements, and disposal methods.

• The collection method and the volume of debris should be documented.

• Verify that chains-of-custody of the collected materials are maintained. Based on the

condition and type of materials, this debris may require special handling,

containerization, and disposal, including incineration.

Chemical, Biological, Radiological, and Nuclear-Contaminated Debris

Chemical, biological, radiological, and nuclear (CBRN)-contaminated debris is any debris

contaminated by chemical, biological, radiological, or nuclear materials as a result of a natural or

man-made disaster, such as a weapon of mass destruction event. The clearance, removal, and

disposal of CBRN-contaminated debris should be performed in accordance with applicable

Federal statutes, regulations, policies, and other guidance documents. When monitoring:

• Man-made disasters may create debris that is considered evidence as part of a crime

scene. Law enforcement officials may need to clear the activities before debris operations

can begin. Monitors should ensure the CBRN-contaminated debris is cleared by law

enforcement officials before removal so as not to undermine the integrity of the crime

scene. Debris operations may also proceed concurrently with incident investigations.

• Be aware of the types of evidentiary material being sought in case CBRN-contaminated

debris is encountered outside the identified crime scene area.

• CBRN-contaminated debris may be either disposed of or taken to a special collection

area for further processing. Verify and document that separation, processing, and disposal

follow the prescribed procedures.

Type of Waste

Examples

Hazardous Waste

Any debris containing any of the characteristics of

ignitability, corrosivity, reactivity, or toxicity

Household Hazardous Waste

Any hazardous debris disposed of by resident consumers

(some paints, stains, varnishes, solvents, and pesticides)

Infectious Waste

Any debris that can cause infections in humans (animal

waste, human blood and blood products, medical waste,

pathological waste, and discarded sharps (needles, scalpels,

or broken medical instruments))

Chemical, Biological, Radiological,

and Nuclear-Contaminated Debris

Any debris contaminated by chemical, biological,

radiological, or nuclear materials (weapons of mass

destruction)

Chapter 6: Documenting Eligible Work and Costs

21

Chapter 6: Documenting Eligible Work and Costs

With proper documentation, an Applicant may fully account for debris clearance and removal

costs incurred as a result of a Presidentially declared disaster. A load ticket provides the most

comprehensive information and a paper trail for FEMA PA program reimbursement. To support

the documentation provided by the load tickets, monitors should use tower-monitoring logs,

roving monitor reports, daily issue logs, and truck certification forms as part of their reporting

process. Samples of these forms are included in Appendix B: Sample Debris Monitoring Plan

and Monitoring Forms. When ADMS technology is used, the data generated should clearly

display loading monitor and tower/site monitor names, load times, and locations so that an

individual’s daily activities can be easily reviewed.

The following describes the types of documentation that should be provided to FEMA PA to

substantiate eligible work performed and associated costs for grant funding.

Documenting Force Account Debris Operation Costs

When an Applicant uses its own force account resources to perform debris removal and disposal

work, requests for reimbursement should be supported by documentation of the labor and

equipment charges incurred in the operation. This includes:

• Payroll records of full-time and temporary employees working debris removal operations.

• Records of Applicant-owned equipment used in debris removal operations, including a

record of equipment hours in service, associated equipment rates, and operator name.

• Invoices of rental equipment used in the debris removal operation.

• Documentation from permitted final disposal locations including:

o Temporary disposal permits from State DEQ if temp site is utilized and Municipal

Solid Waste Permit number for final disposition.

o Invoices of disposal tipping fees.

o Quantities of debris disposed.

• Documentation of the location of the debris removal activities demonstrating FEMA

debris eligibility and/or documentation certifying that FEMA-eligible debris work was

performed.

Documenting Contractor Debris Operation Costs

The debris operation, if completed by contract, should have adequate controls in place to ensure

contract terms are adhered to, that only specified debris is removed, and proper documentation is

collected and compiled for payment purposes. Applicants should monitor the performance of

their contractors and ensure that they comply with their contract terms and conditions.

34

When an Applicant has hired a contractor to perform debris removal work, documentation

should correspond with the invoiced costs and line item prices of the debris removal contract.

This documentation will be provided on monitoring forms and reports (refer to Appendix B:

34

Refer to PDAT resources when procuring with Federal grant awards: www.fema.gov/procurement-disaster-

assistance-team.

Chapter 6: Documenting Eligible Work and Costs

22

Sample Debris Monitoring Plan and Monitoring Forms), including load tickets and tower logs,

which will provide information on:

• Locations of debris removal.

• Type of debris removed.

• FEMA debris removal eligibility determination.

• Debris quantities (volume or weight determined at inspection site).

• Identification of debris hauling truck/trailer and contractor.

• Location of permitted final debris disposal site.

• Documentation of labor, equipment, and materials charges including hours of service and

associated charges (for time and materials contracts).

• Documentation of quantities of debris reduced or recycled at DMSs and associated

detailed charges.

• Invoices of disposal tipping fees.

In addition to the load tickets, summaries of the information included in the load tickets are

typically provided in support of an Applicant’s PA funding request. FEMA and the Recipient

may also request to see all backup supporting documentation and reports, including truck

certification forms, tower logs, roving monitor reports, and daily issue logs used to substantiate

claimed costs (refer to Appendix B: Sample Debris Monitoring Plan and Monitoring Forms).

Monitoring Reports

Applicants should have debris monitors submit daily reports on operational issues, including

DMS operations and safety issues, to promote situational awareness and help identify and

resolve issues. Regular reporting promotes quality assurance and provides the Applicant with a

consistent accounting of operations, issues, and costs in the field. This information is included in

reports such as tower monitor logs, roving monitor reports, and daily issue logs.

Electronic Load Tickets and Automated Reporting

Historically, debris monitoring operations have used the four-part paper load ticket system.

Depending on the size of the event, the manual process of filling out load tickets, transferring

copies, and entering data for reporting and data compilation purposes can be labor and time

intensive, and can result in human error.

Automated debris management tracking systems provide real-time and automated tracking and

reporting. Electronic load tickets, computer tablets, and systems employing electronic contractor

ID cards allow for instant data tracking, verification, and reporting. Some systems also

incorporate truck tracking systems, global positioning system (GPS) capability, and enhanced

analytical capabilities of debris monitoring data.

FEMA embraces technological advancements and recognizes the potential benefits of these

automated systems. As discussed in Chapter 1: General Eligibility Requirements, reasonable

costs associated with the use of electronic load ticket systems and other automated debris

monitoring systems may be eligible for PA funding.

Appendix A: Field Reference Guides

23

Appendix A: Field References Guides

DEBRIS MONITOR DUTIES AND RESPONSIBILITIES

FEMA

Applicant Debris Monitor

Applicant Field Supervisor

Safety

• Verify safety by

identifying possible

health/safety risks and

requiring proper field

safety gear.

• Ensure contractor is

complying with public and

employee safety standards.

• Ensure safety requirements

on State highways and roads

are observed during debris

operations (load limits, truck

covers, etc.).

• Be familiar with and maintain/

implement all safety

requirements.

Eligibility

• Verify compliance with

FEMA PA program

requirements (i.e., provide

eligibility guidance,

timeframe requirements,

and documentation and

reporting requirements).

• Verify compliance with

FEMA PA program

requirements.

• Ensure only eligible debris is

removed. Notify the field

supervisor of any ineligible

debris removal.

• Ensure that a reasonable level of

effort is applied to the

monitoring process,

commensurate with the debris

operations and the schedule.

• Ensure only eligible debris is

noted on tickets. Ensure any

ineligible activities are noted and

the associated tickets are not

recommended for invoicing.

Compliance

• Spot check debris loading,

staging, reduction, and

disposal sites to ensure

compliance with eligibility

requirements.

• Report any noncompliance,

misconduct, or other

negative actions to the

assigned FEMA staff for

appropriate coordination

and resolution with

State/Tribal and Applicant

officials.

• Ensure all work complies

with local ordinances and

SLTT and Federal

regulations.

• Monitor environmental

compliance on all debris

management sites (DMSs).

• Monitor preservation of

places and buildings

pertaining to the State’s

historic and archaeological

treasures.

• Obtain and become familiar with

the requirements outlined in all

debris removal and disposal

contracts to ensure the contract

requirements are implemented

correctly.

• Make unannounced visits to all

loading and disposal sites in an

assigned area.

• Take photographs of all trucks

and trailers used in the debris

operation, to establish a baseline

inventory of equipment.

Appendix A: Field Reference Guides

24

DEBRIS MONITOR DUTIES AND RESPONSIBILITIES

FEMA

Applicant Debris Monitor

Applicant Field Supervisor

Debris Operations

• Validate certification of

trucks and trailers.

• Evaluate operational

efficiency.

• Oversee documentation

requirements.

• Ensure trucks are measured,

certified, and operated

properly.

• Ensure trucks are loaded

properly and loads are

accurately evaluated.

• Verify load tickets are

properly completed and

controlled.

• Ensure only debris from

approved public areas is

removed.

• Assist in measuring all debris

hauling trucks and trailers for

truck certification. Coordinate

with the appropriate contractor

representatives, if applicable, to

confirm certification completion.

Management and Oversight

• Not Applicable

• Ensure debris sites are

properly mobilized and

administered.

• Ensure accurate

recordkeeping and

appropriate documentation.

• Ensure contractor activities

are conducted as mandated in

contractor SOW.

• Serve as the first line of

management for debris monitors

and assist with any questions or

conflicts that arise.

• Prepare a daily written report of

all activities observed and

include photographs.

• Be familiar with all phases of

debris management operations.

Appendix A: Field Reference Guides

25

DEBRIS MONITOR DUTIES AND RESPONSIBILITIES

Applicant Debris Loading Monitor

Safety

• Check area for safety considerations, such as downed power lines, children playing in the area, traffic

control needs, and safe operation of trucks and equipment.

• Implement all safety requirements.

• Before work begins, inspect areas to identify covered utility meters, transformers, fire hydrants, mailboxes,

etc. (as a baseline to account for any damage as a result of the debris removal operations).

• Ensure that debris loads are contained properly before leaving the loading area.

Eligibility

• Determine whether each load is to be claimed for reimbursement based on established eligibility criteria,

and mark load tickets, if ineligible, for FEMA reimbursement.

• Validate eligible hazardous trees, including hangers, leaners, and stumps.

• Verify global positioning system (GPS) readings or an address/location for leaning trees, trees with hanging

limbs, and uprooted/exposed stumps that constitute an immediate threat; a separate ticket should be written

for these items if required in the contract.

• Do not issue tickets for trucks that arrive at pick-up sites already loaded or partially loaded.

• Ensure that force account labor and debris contractor work is within the assigned SOW.

Compliance

• Obtain and become familiar with the requirements outlined in all debris removal and disposal contracts to

ensure the contract requirements are implemented correctly.

• Report to field supervisor if debris removal work does not comply with all local ordinances as well as SLTT

and Federal regulations (i.e., improper disposal of hazardous wastes).

Debris Operations

• Ensure that hazardous wastes are not mixed into loads.

• Record the types of equipment used (for time-and-materials contracts).

• Record the hours equipment was used, including down time of each piece of equipment by day (for time-

and-materials contracts).

• Ensure that only debris specified by the Applicant is collected for loading and hauling.

• Ensure only debris from approved public areas is removed.

• Ensure the work area is clear of debris before equipment is moved to a new loading area.

• Prepare complete and accurate load tickets.

• Issue load tickets for each debris load to the truck driver.

• Evaluate and record performance and productivity of debris removal crews.

Communication

• Remain in constant contact with debris management/dispatch center or field supervisor.

• Report issues (such as safety concerns, contractor non-compliance, and improper equipment use) to field

supervisor.

• Maintain a log of debris operations issues.

• Photograph and provide written documentation of any damage to utility components, driveways, road

surfaces, private property, vehicles, etc.

• Perform other duties as directed by designated debris management personnel.

Appendix A: Field Reference Guides

26

DEBRIS MONITOR DUTIES AND RESPONSIBILITIES

Applicant Debris Tower/Site Monitor

Safety

• Check area for safety considerations, such as downed power lines, children playing in the area, traffic

control needs, and safe operation of trucks and equipment.

• Implement all safety requirements.

Compliance

• Obtain and become familiar with the requirements outlined in all debris removal and disposal contracts to

ensure the contract requirements are implemented correctly.

• Report to field supervisor if debris removal work does not comply with all local ordinances as well as SLTT

and Federal regulations (i.e., improper disposal of hazardous wastes).

• Coordinate with management to ensure and verify that DMSs are properly permitted for the debris reduction

methods utilized.

Debris Operations

• Ensure that hazardous wastes are not mixed into loads.

• Record the types of equipment used (for time-and-materials contracts).

• Record the hours equipment was used, including down time of each piece of equipment by day (for time-

and-materials contracts).

• Accurately measure and document load hauling compartments for trucks and trailers to compute volume

capacity in CY for each truck and trailer prior to its commencement of debris hauling operations (recertify

on regular basis).

• Recertify and re-measure truck capacities on a regular basis.

• Ensure that truck loads are accurately credited.

o Estimate the percentage of full capacity for each truck or trailer load.

o Ensure trucks are not artificially loaded (e.g., debris is wetted, fluffed, or not compacted).

• Verify the origination of debris and the destination either through load tickets or electronic monitoring

(ADMS).

• Physically control load tickets.

• Ensure that all debris is removed from trucks at DMSs.

• Monitor site development and restoration of DMSs.

• Oversee debris reduction (grinding, burning, chipping, etc.).

Communication

• Remain in constant contact with debris management/dispatch center or field supervisor.

• Report issues (such as safety concerns, contractor non-compliance, and improper equipment use) to field

supervisor.

Appendix A: Field Reference Guides

27

GENERAL DEBRIS MONITORING TIPS AND CONSIDERATIONS

Equipment

• The most common unit of measurement for vegetative and C&D debris is the CY. Debris trucks are

evaluated for capacity at the DMS or final disposal sites. Applicants should require contractors to use

appropriate equipment to load debris efficiently so that the maximum level of compaction can be

achieved to facilitate expeditious removal of debris from the public rights-of-way.

• All trucks and trailers will be measured and placarded with the measured capacity of the vehicle. The

Applicant should photograph all trucks/trailers to ensure that the capacity is not reduced by removing

sideboards or tailgates on the truck as the debris removal operation unfolds.

• Equipment limitations affect the maximum loading capacity of some vehicles.

• Hand-loaded trucks and trailers cannot achieve compaction levels comparable to mechanically loaded

vehicles. This effectively reduces the capacity of the hand-loaded truck or trailer compared to a truck or

trailer that is loaded mechanically. Therefore, FEMA only reimburses 50 percent of the debris monitor’s

observed capacity for a hand-loaded truck or trailer. Example: If a hand-loaded truck or trailer appears to

be 100 percent full, that load should be recorded at 50 percent. Hand-loading debris in trucks or trailers

does not achieve maximum compaction, and as a result, debris removal operations take longer to

complete. A hand-loaded truck hauls less debris by weight per CY than a mechanically loaded truck.

35

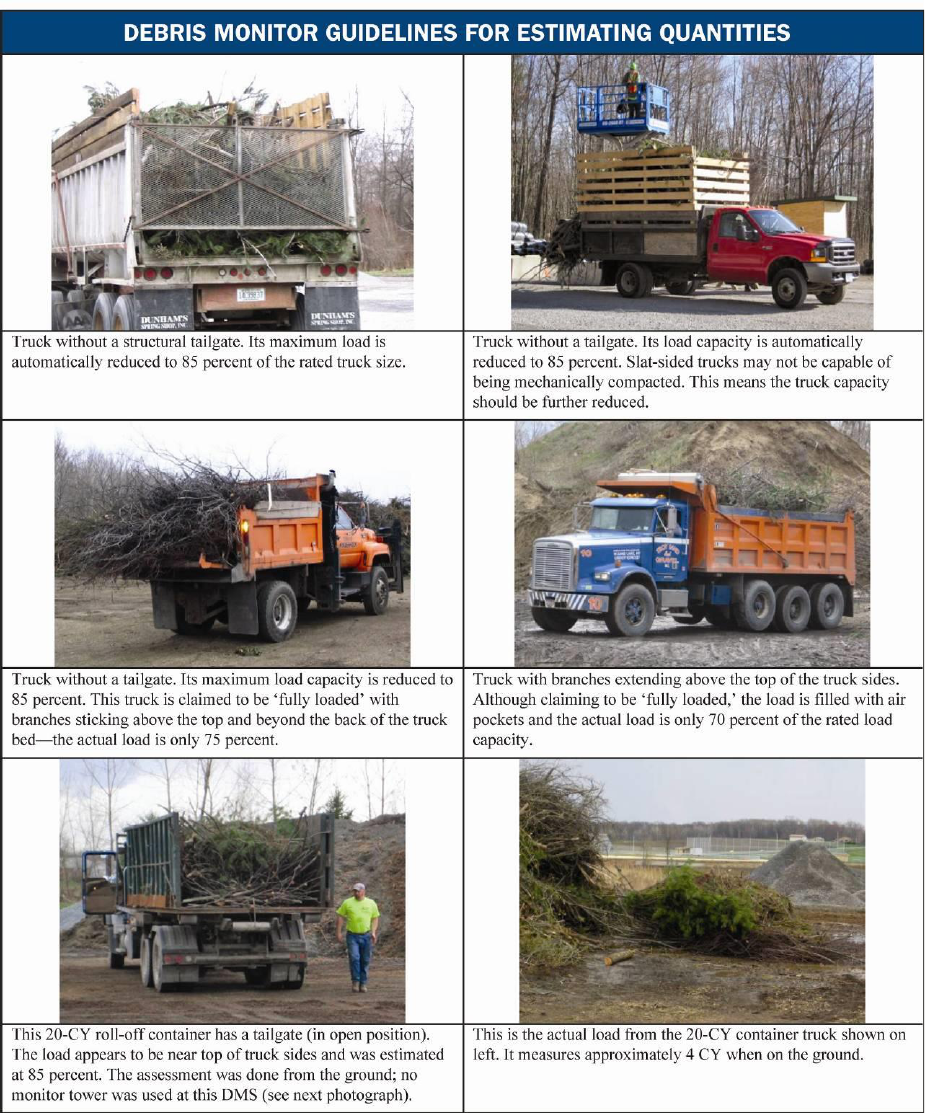

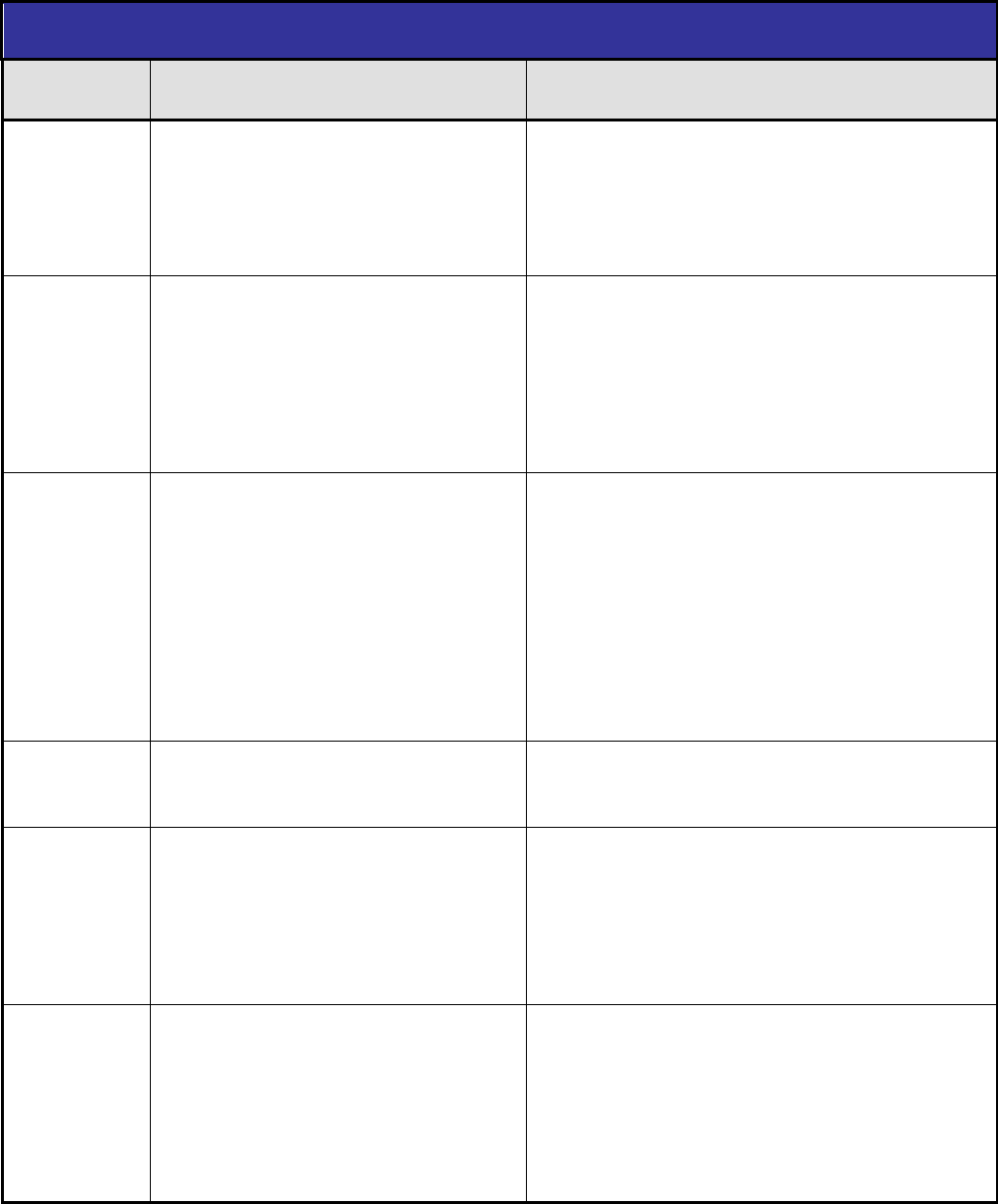

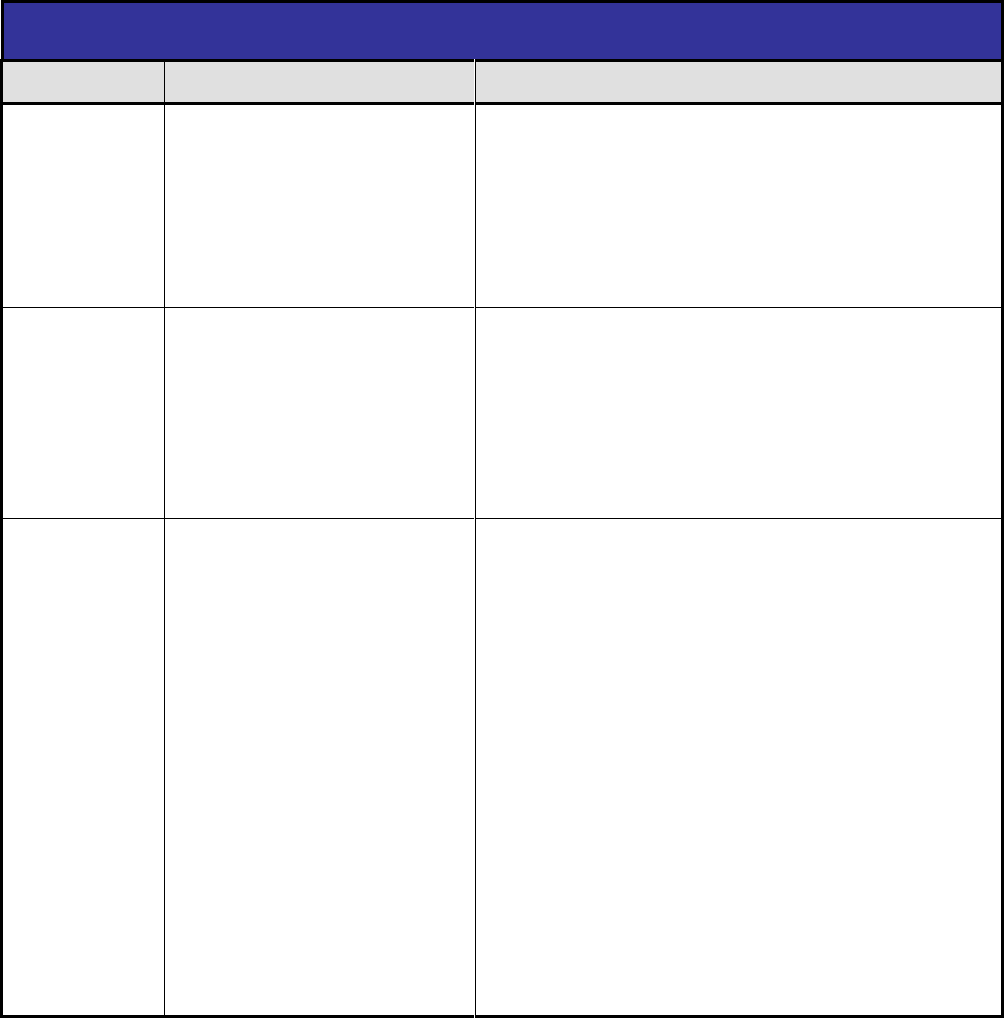

• A truck with no tailgate or no solid tailgate cannot be compacted to its full capacity; therefore, FEMA

would automatically apply a 15 percent reduction to the total quantity and only considers a maximum of

85 percent of the certified truck capacity for reimbursement purposes.

Debris Challenges

• Vegetative Debris Challenges: Hazardous leaners, stumps, and hangers can be difficult to measure

consistently (particularly because monitors must determine if leaners are leaning at least 30 degrees and

eligible to be cut). Debris monitors should have a map of all roads and work with the Applicant’s public