Hardware Manual

Trademark acknowledgments

TSP100: Star Micronics Co., Ltd.

Notice

• All rights reserved. Reproduction of any part of this manual in any form whatsoever, without STAR’s express

permission is forbidden.

• The contents of this manual are subject to change without notice.

• All efforts have been made to ensure the accuracy of the contents of this manual at the time of going to press.

However, should any errors be detected, STAR would greatly appreciate being informed of them.

• The above notwithstanding, STAR can assume no responsibility for any errors in this manual.

Copyright

©

2005-2011 Star Micronics Co., Ltd.

Federal Communications Commission

Radio Frequency Interference

Statement

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device

may not cause harmful interference, and (2) this device must accept any interference received, including interference that

may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instruction manual, may cause harmful interference to radio

communications. Operation of this equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his own expense.

This statement will be applied only for the printers marketed in U.S.A.

FCC WARNING

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

For compliance with the Federal Noise Interference Standard, this equipment requires a shielded cable.

For RF interference suppression, if a ferrite core is provided with this device, afx it to the interface cable

Statement of

The Canadian Department of Communications

Radio Interference Regulationst

This Class A digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

The above statement applies only to printers marketed in Canada.

TABLE OF CONTENTS

1. Unpacking and Installation .....................................................................................................................1

1-1. Unpacking ....................................................................................................................................1

2. Parts Identication and Nomenclature ..................................................................................................3

2-1. U Model .......................................................................................................................................3

2-2. PU Model .....................................................................................................................................4

2-3. Choosing a place for the printer ...................................................................................................5

3. Setup ..........................................................................................................................................................6

3-1. Connecting the USB/PoweredUSB Cable to the Printer .............................................................6

3-2. Connecting to a Peripheral Unit ...................................................................................................9

3-3. Loading the Roll Paper ..............................................................................................................10

3-4. Connecting the USB/PoweredUSB Cable to the PC .................................................................13

3-5. Connecting the Power Cord .......................................................................................................14

3-6. Turning Power On ......................................................................................................................16

4. Attaching the Accessories ......................................................................................................................17

4-1. Attaching the Holder Plate .........................................................................................................17

4-2. Attaching the Rubber Feet .........................................................................................................18

4-3. Switch Cover Installation ...........................................................................................................19

5. Thermal Roll Paper Specication .........................................................................................................20

5-1. Roll paper specication ..............................................................................................................20

5-2. Recommended paper ..................................................................................................................20

6. Control Panel and Other Functions .....................................................................................................22

6-1. Control Panel .............................................................................................................................22

6-2. Errors ..........................................................................................................................................22

6-3. Self-Printing ...............................................................................................................................24

7. Preventing and Clearing Paper Jams ...................................................................................................25

7-1. Preventing Paper Jams ...............................................................................................................25

7-2. Removing Paper Jam .................................................................................................................25

7-3. Releasing a Locked Cutter (Auto Cutter Mode only) ................................................................26

8. Periodical Cleaning ................................................................................................................................28

8-1. Cleaning the Thermal Head .......................................................................................................28

8-2. Cleaning the Paper Holder .........................................................................................................28

9. Peripheral Unit Drive Circuit ...............................................................................................................29

10. Specications ........................................................................................................................................31

10-1. General Specications ...............................................................................................................31

10-2. Auto Cutter Specications .........................................................................................................32

10-3. Interface .....................................................................................................................................32

10-4. Electrical Characteristics ...........................................................................................................32

10-5. Environmental Requirements .....................................................................................................35

10-6. Reliability ...................................................................................................................................36

11. DIP Switch Settings ..............................................................................................................................37

Please access the following URL

http://www.star-m.jp/eng/dl/dl02.htm

for the latest revision of the manual.

– 1 –

1-1. Unpacking

After unpacking the unit, check that all the necessary accessories are included in the package.

1-1-1. U Model

Fig. 1-1 Unpacking

If anything is missing, contact the dealer where you bought the printer and ask them to sup-

ply the missing part. Note that it is a good idea to keep the original box and all the packing

materials just in case you need to pack the printer up again and send it somewhere at a later

date.

1. Unpacking and Installation

Printer

Paper roll holder

Holder plate

Switch cover

USB cable

Power cord

Rubber feet

CD-ROM

Installation sheet

Roll paper

Screws

– 2 –

1-1-2. PU Model

[Options]

AC adapter

STAR, Adapter PS60A-24A

PoweredUSB cable (Y cable)

PoweredUSB 24V to USB-B & HOSIDEN-M

USB cable

STAR, USB Cable 1.8M TSP1

PoweredUSB cable (straight type)

PoweredUSB 24V to 1

×

8

[Recommended cables]

Paper roll holder

Holder plate

Printer

Switch cover

Screws

Rubber feet

Roll paper

Connector cover A

CD-ROM

Installation sheet

– 3 –

2-1. U Model

2. Parts Identication and Nomenclature

Cover open lever

Push this lever in the

direction of the arrow to

open the printer cover.

Control panel

Features LED indicators to indicate

printer status and switches to oper-

ate the printer.

Power switch

Used to turn on/off

power to the printer.

Power connector

For connection of the

power cord.

Peripheral drive connector

Connects to peripheral

units such as cash draw-

ers, etc.

Do not connect this to a

telephone.

USB connector

For connection to a

host computer using a

USB cable.

Printer cover

Open this cover to load or

replace paper.

– 4 –

2-2. PU Model

Cover open lever

Push this lever in the

direction of the arrow to

open the printer cover.

Peripheral drive connector

Connects to peripheral units such as

cash drawers, etc.

Do not connect this to a telephone.

Printer cover

Open this cover to load or

replace paper.

Control panel

Features LED indicators to indi-

cate printer status and switches

to operate the printer.

Power switch

Used to turn on/off

power to the printer.

Power connector

For connection of the AC adapter or

the PoweredUSB cable (Y cable).

USB connector

For connection to a

host computer using

the USB cable or

PoweredUSB cable

(Y cable).

PoweredUSB connector

For connection to a host

computer using the Pow-

eredUSB cable (straight

type).

– 5 –

2-3. Choosing a place for the printer

Before actually unpacking the printer, you should take a few minutes to think about

where you plan to use it. Remember the following points when doing this.

✓

Choose a rm, level surface where the printer will not be exposed to vibration.

✓

The power outlet you plan to connect to for power should be nearby and unobstruct-

ed.

✓

Make sure that the printer is close enough to your host computer for you to connect

the two.

✓

Make sure that the printer is not exposed to direct sunlight.

✓

Make sure that the printer is well away from heaters and other sources of extreme

heat.

✓

Make sure that the surrounding area is clean, dry, and free of dust.

✓

Make sure that the printer is connected to a reliable power outlet. It should not be

on the same electric circuit as copiers, refrigerators, or other appliances that cause

power spikes.

✓

Make sure that the room where you are using the printer is not too humid.

✓

This device employs a DC motor and switches that have an electrical contact point.

Avoid using the device in environments where silicon gas can become volatile.

WARNING

✓

Shut down your equipment immediately if it produces smoke, a strange odor, or un-

usual noise. Immediately unplug the equipment and contact your dealer for advice.

✓

Never attempt to repair this product yourself. Improper repair work can be danger-

ous.

✓

Never disassemble or modify this product. Tampering with this product may result

in injury, re, or electric shock.

– 6 –

3. Setup

3-1. Connecting the USB/PoweredUSB Cable to the Printer

3-1-1. U Model

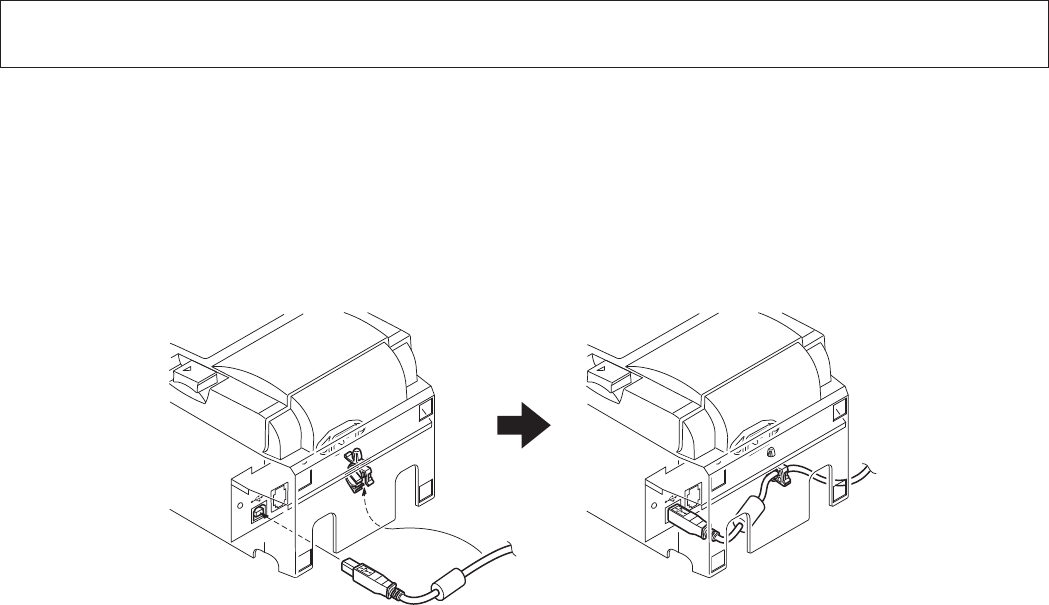

Pass the cable through the cable support as shown. Then, connect the USB interface cable to

the printer.

– 7 –

3-1-2. PU Model

CAUTION

Make sure that the printer is turned off before connecting the PoweredUSB cable (Y cable) or

PoweredUSB cable (straight type).

(1) According to the cable used, install the connector cover onto the printer to prevent im-

proper cable connections.

USB cable or PoweredUSB cable (Y cable) ............Connector cover A

PoweredUSB cable (straight type) ..........................Connector cover B

The printer is shipped with connector cover B installed. This cover does not need to be

removed when using the PoweredUSB cable (straight type). When using a USB cable or

PoweredUSB cable (Y cable), remove connector cover (B) and install connector cover (A)

to the printer until a click is heard.

To remove connector cover (B), use a at-head screwdriver as shown to push in the hook

on the cover.

Connector cover A

Connector cover B

Hook

Connector cover B

Hook

1 2

3 4

– 8 –

(2) Connect the interface cable to the printer as shown. When using the USB cable, secure

the cable with the hook.

USB cable

PoweredUSB cable (Y cable)

PoweredUSB cable (straight type)

– 9 –

3-2. Connecting to a Peripheral Unit

You can connect a peripheral unit to the printer using a modular plug. The following de-

scribes how to install the ferrite core and make the actual connection. See “Modular plug” on

page 30 PoweredUSB for details about the type of modular plug that is required. Note that

this printer does not come with a modular plug or wire, so it is up to you to obtain one that

suits your needs.

CAUTION

Make sure that the printer is turned off and unplugged from the AC outlet and that the com-

puter is turned off before making connections.

(1) Connect the peripheral drive cable to the connector on the rear panel of the printer.

CAUTION

Do not connect a telephone line into the peripheral drive connector. Failure to observe this

may result in damage to the printer.

Also, for safety purposes, do not connect wiring to the external drive connector if there is a

chance it may carry peripheral voltage.

[U Model]

[PU Model]

– 10 –

3-3. Loading the Roll Paper

Be sure to use roll paper that matches the printer’s specication.

When using a paper roll with an 57.5 mm width, install the paper roll holder as described on

the following page.

1) Push the cover open lever, and open the print-

er cover.

2) While observing the direction of the roll, set

the paper roll into the hollow, and pull on the

leading edge of the paper toward you.

Note: When using a paper roll with an 57.5 mm

width, install the paper roll holder in the

groove in the printer.

If a paper roll with a 57.5 mm width

has been used, a paper roll with a 79.5

mm width cannot be used. (Changing

from the smaller roll to a larger roll

will cause part of the print head to rub

against the platen and deteriorate.)

3) Push down both sides of the printer cover to

close.

Note: Make sure that the printer cover is se-

curely closed.

4) Tear Bar Model:

Tear off the paper as shown.

Auto Cutter Model:

If the printer cover is closed after turning on

the power, the cutter operates automatically

and the front end of the paper is cut.

Cover open lever

Roll paper

Tear Bar Model

Paper roll holder

– 11 –

WARNING

1) Do not touch the cutter blade.

• Thereisacutterinsidethepaperoutletslot.Notonlyshouldyounotputyourhandin

the paper outlet slot while printing is in progress, never put your hand into the outlet

even when printing is not in progress.

• Theprintercovercanbeopenedwhenreplacingthepaper.However,sincethecutter

blade is on the inside of the printer cover, be careful not to place your face or hands

too close to the cutter blade.

2) During and immediately after printing, the area around the thermal head is very hot. Do

not touch it, as you could be burned.

3) Unplug the equipment immediately if it produces smoke, a strange odor, or unusual noise

and contact your dealer for advice.

4) Neverattempttorepairthisproductyourself.Improperrepairworkcanbedangerous.

5) Neverdisassembleormodifythisproduct.Tamperingwiththisproductmayresultin

injury,re,orelectricshock.

Caution Symbol

These labels are located near the thermal print head.

Because the thermal print head is hot immediately after printing, do not

touch it. Static electricity can damage the thermal print head. To protect the

thermal print head from static electricity, do not touch it.

This symbol is placed near the cutter.

Never touch the cutter blade, as you could injure your ngers.

This symbol is placed near the peripheral drive connector.

Do not connect this to a telephone.

This symbol label or stamp is placed near the screws securing the case or

the protective plate, which should not be opened by individuals other than

service personnel. Individuals, other than service personnel, should not

remove these screws. High voltage areas in the case can be dangerous.

Thermal head

– 12 –

CAUTION

1) Do not operate the cover open lever while pressing on the printer cover with your hand.

2) Do not push the cover open lever and open the printer cover when printing is in progress

or when the auto cutter is operating.

3) Do not push out paper while the printer cover is closed.

4) TheheatingelementandthedriverICofthethermalheadareeasilydamaged.Donot

touch them with metal objects, sandpaper, etc.

5) Printing quality may suffer if the thermal head heating element becomes soiled by being

touched with your hands. Do not touch the thermal head heating element.

6) ThereisariskofdamagetothedriverICofthethermalheadfromstaticelectricity.

NeverdirectlytouchtheIC.

7) The printing quality and working life of the thermal head cannot be guaranteed if any

paperotherthanthatrecommendedisused.Inparticular,papercontaining[Na+,K+,

C1-] may drastically reduce the working life of the thermal head. Please exercise cau-

tion.

8) Do not operate the printer if there is moisture on the front surface of the head from con-

densation, etc.

9) Aprintedpieceofthermalpapermaybecomeelectricallycharged.Iftheprinteris

placed vertically or mounted on a wall, the cut piece of paper may stick to the printer,

instead of falling. Beware that this could cause a problem if you use a stacker that stores

the pieces of paper that fall freely.

10) Do not change the paper width during use. The thermal printing head, rubber roller, and

cutter wear differently according to the paper width. This can cause the printing or cutter

movement to malfunction.

11) Do not transport the printer with its cover open and holding it by the cover.

12) Do not forcibly pull on the interface cable, power cord, or cash drawer cable that is con-

nected. To detach a connector, make sure to grasp it at the connector portion, without

applying excessive stress on the connector at the printer

13) Ifyourprintergetshang-up,youmustresetitbypluggingout/intheUSBcable.How-

ever,theintervalsofperpluggingout/inmustbe5secondsormore.Shorterintervalmay

cause malfunction.

14) Do not turn off the computer or put the cpmputer in stand-by mode during printing.

15) Do not unplug the power cord or disconnect the USB cable during it is working.

Notes on Using the Auto Cutter

1) Ifthecutterisnotinitshomepositionafteranerror,rsteliminatethecauseoftheer-

ror;then,turnthepowerbackON.

2) A margin of 5 mm or more is recommended from the end of the printed area to the cutting

position.

3) Do not attempt to remove the paper during a cut, as this can cause a paper jam

– 13 –

3-4. Connecting the USB/PoweredUSB Cable to the PC

3-4-1. U Model

Connect the USB interface cable to a USB port of your PC.

3-4-2. PU Model

CAUTION

Make sure that the PC is turned off before connecting the PoweredUSB cable (Y cable) or

PoweredUSB cable (straight type).

Connecting the USB cable

Connecting the PoweredUSB cable (Y cable) or

PoweredUSB cable (straight type)

Connect the interface cable to a USB port of your PC.

– 14 –

3-5. Connecting the Power Cord

3-5-1. U Model

Note: Before connecting/disconnecting the power cord, make sure that power to the printer

and all the devices connected to the printer is turned off. Also make sure the power

cable plug is disconnected from the AC outlet.

(1) Check the label on the back or bottom of the printer to make sure its voltage matches

that of the AC outlet. Also make sure the plug on the power cord matches the AC outlet.

(2) If the power cord is not attached to the printer, plug the appropriate end into the AC inlet

on the back of the printer.

(3) Plug the power cord into a properly grounded AC outlet.

CAUTION

If the voltage shown on the label on the bottom of your printer does not

match the voltage for your area, contact your dealer immediately.

– 15 –

3-5-2. PU Model

Note: Before connecting/disconnecting the AC adapter, make sure that power to the printer

and all the devices connected to the printer are turned off. Also make sure the power

cable plug is disconnected from the AC outlet.

(1) Connect the AC adapter to the power cable.

Note: Use only the standard AC adapter and power cable.

(2) Connect AC adapter to the connector on the printer.

(3) Insert the power cable plug into an AC outlet.

CAUTION

When disconnecting the cable, take hold of the cable connector to pull it

out. Releasing the lock makes it easy to disconnect the connector.

Pulling the cable excessively could cause damage to the connector.

AC outlet

– 16 –

3-6. Turning Power On

Make sure that the Power cord has been connected as described in 3-6.

(1) Turn ON the power switch located on the front of the printer.

The POWER lamp on the control panel will light up.

CAUTION

We recommend that you unplug the printer from the power outlet whenever you do not plan to

use it for long periods. Because of this, you should locate the printer so that the power outlet

it is plugged into is nearby and easy to access.

WhenanSwitchcoverisafxedtotheprinterabovethepowerswitch,theON/OFFmarksof

thepowerswitchmaybehidden.Ifthisoccurs,removethepowercordfromtheoutlettoturn

the printer OFF.

Power switch

– 17 –

4. Attaching the Accessories

The following accessories are necessary when mounting the printer to a wall.

• Holder plate and two angeless screws

The following accessories are necessary when positioning the printer vertically.

• Four rubber feet

The following accessories do not necessarily have to be attached. Attach it if necessary.

• Switch cover

4-1. Attaching the Holder Plate

• The holder plate is attached to the printer using the included screws and is hooked onto

screws that are installed into the wall.

• The screws on the wall are not included.

Use commercially available screws (4 mm diameter) that are suitable for the wall material

(wood, steel beam, concrete, etc.).

• The printer’s weight is approximately 2.4 kg when the largest diameter roll paper is loaded.

Use screws on the wall that have both shear strength and pulling-out strength to withstand

a force of at least 12 kgf (118 N).

Precautions regarding installation

CAUTION

This caution indicates information that, if ignored, could lead to personal injury or property

damage.

• Besuretohavequaliedpersonnelinstallthespeciedscrewsandprintertothewall.

Star is not responsible for any accidents or injuries that occur as a result of improper in-

stallation,misuse,ormodications.

Especially when installing the printer at a high location, make sure that the printer is se-

curely installed to the wall.

Iftheprinterisnotinstalledsecurelyandfalls,personalinjuryordamagetotheprinter

may result.

• Makesurethatthemountingsurfaceandinstallationscrewsarestrongenoughtoinstall

the printer.

Securely install the printer so that the weight of the printer and any connected cables will

not cause the printer to fall.

Otherwise, personal injury or damage to the printer may result.

• Donotinstalltheprinterinanunstablelocationoralocationthatisexposedtovibration

and shocks.

Iftheprinterfalls,personalinjuryordamagetotheprintermayresult.

– 18 –

4-2. Attaching the Rubber Feet

(1) Attach the four rubber feet in the positions

shown in the gure.

Ensure that any soiling has been completely

wiped off before attaching the rubber feet.

(2) Position the printer over the screws, etc., on

the wall and then slide it downward to set it

in place.

After setting the printer in place, check the

screws on the wall again to make sure that

they are able to support the printer’s weight.

CAUTION

• Theprinter’sweightisapproximately2.4 kg

when the largest diameter roll paper is load-

ed.

• Usescrewsonthewallthathavebothshear

strength and pulling-out strength to with-

standaforceofatleast12kgf(118 N).

(3) Push the cover open lever, and open the print-

er cover.

(4) Insert the roll paper as shown.

(1) Attach the holding plate to the printer. Then

tighten the two screws that were supplied to

secure it in place.

ø4

Flangeless screws

2 to 3 mm

ø7 or more

– 19 –

4-3. Switch Cover Installation

It is not necessary to install the switch cover. Only install it if it is necessary for you. By in-

stalling the switch cover, the following become possible.

• Preventing the power switch from being operated by mistake.

• Ensuring that other people can not easily operate the power switch.

Install the switch cover as shown in the diagram below.

The power switch can be turned ON (

|

) and OFF (O) by inserting a narrow instrument (ball

pen etc.) in the holes in the switch cover.

CAUTION

We recommend that you unplug the printer from the power outlet whenever you do not plan to

use it for long periods. Because of this, you should locate the printer so that the power outlet

it is plugged into is nearby and easy to access.

(2) Push the cover open lever, and open the print-

er cover.

(3) Insert the roll paper as shown.

– 20 –

5. Thermal Roll Paper Specication

When consumable parts have run out, use those specied below.

5-1. Roll paper specication

Thermal paper

Thickness: 57~85 µm (excluding Mitsubishi HiTec F5041)

Note: When using thin paper with a thickness of less than 65 μm, only the F5041

(Mitsubishi HiTec Paper Flensburg GmbH),TF50KS-E2D (Nippon Paper

Industries) and P300/P310 (KSP) paper types are recommended.

Width: 79.5±0.5 mm (57.5±0.5 mm when the paper roller holder is used)

Outer roll diameter: ø83 mm or less

Take up paper roll width: 80 mm or (58 mm when the paper roller holder is used)

Core outer/inner diameter: Core outer Core inner

ø18±1 mm ø12±1 mm

Printed surface: Outer edge of roll

Tail end handling: Do not use paste or glue to secure the roll paper or its core.

Do not fold the tail end of the paper.

5-2. Recommended paper

Note:

1) The print density may vary depending on the type of roll paper, operating environment,

and power consumption mode.

2) A reader or scanner may not be able to scan a printed bar code or characters depending

on the print density. Make sure that your reader or scanner is able to scan correctly be-

forehand.

5-2-1. U Model

Manufacturer Product name Quality characteristics/Use

Paper thickness

(µm)

Mitsubishi Paper Mills

Limited

P220AG normal type paper 65

HP220A high image stability paper 65

HP220AB-1 high image stability paper 75

Mitsubishi HiTec Paper

Flensburg GmbH

F5041 normal type paper 60

Oji Paper Co., Ltd.

PD150R normal type paper 75

PD160R high image stability paper 75

PD170R high image stability paper 75

PD190R middle image stability paper 75

Nippon Paper Industries TF50KS-E2D normal type paper 59

Kanzaki Specialty Papers

Inc. (KSP)

P320RB 2 color paper: Red & Black 65

P320BB 2 color paper: Blue & Blac 65

P300 / P310 normal type paper 57 / 58

Note: The P300/P310 (KSP) paper types cannot be used when the printer is positioned vertically.

+ 0.5

-1

+ 0.5

-1

– 21 –

5-2-2. PU Model

Note:

Access the following URL for the information of the recommended paper.

http://www.star-m.jp/eng/dl/dl02.htm

Manufacturer Product name Quality characteristics/Use

Paper thickness

(µm)

Power consumption

mode

Mitsubishi Paper Mills

Limited

P220AG normal type paper 65

HP220A high image stability paper 65

HP220AB-1 high image stability paper 75

Mitsubishi HiTec Paper

Flensburg GmbH

F5041 normal type paper 60

Oji Paper Co., Ltd.

PD150R normal type paper 75

PD160R high image stability paper 75

PD170R high image stability paper 75

PD190R middle image stability paper 75

Nippon Paper Industries TF50KS-E2D normal type paper 59

Kanzaki Specialty Papers

Inc. (KSP)

P320RB 2 color paper: Red & Black 65 Standard mode only

P320BB 2 color paper: Blue & Blac 65 Standard mode only

P300 / P310 normal type paper 57 / 58

Note: The P300/P310 (KSP) paper types cannot be used when the printer is positioned vertically.

– 22 –

6. Control Panel and Other Functions

1

POWER lamp (Green LED)

Lights when the power is ON.

2

ERROR lamp (Red LED)

Indicates various errors in combination

with POWER lamp.

3

FEED button

Press the FEED button to feed roll paper.

6-1. Control Panel

6-2. Errors

1) Automatically recoverable errors

1

POWER lamp (Green LED)

3

FEED button

2

ERROR lamp (Red LED)

Error Description

Head high temperature

detection

Board high temperature

detection

Cover open error

POWER Lamp

Flashes at 0.5-sec-

ond intervals

Flashes at 2-second

intervals

On

ERROR Lamp

Off

Off

On

Recovery Conditions

Automatically recovered after the

print head has cooled.

Automatically recovered after the

board has cooled.

Automatically recovered after the

printer cover is closed.

– 23 –

2) Non-recoverable errors

Error Description

Head thermistor error

Board thermistor error

VM voltage error

VCC voltage error

EEPROM error

USB error

CPU error

RAM error

POWER Lamp

Flashes at 0.5-second inter-

vals

Flashes at 2-second inter-

vals

Off

Flashes at 1-second inter-

vals

Flashes at 0.25-second

intervals

Flashes at 5-second inter-

vals

Off

Off

ERROR Lamp

Flashes at 0.5-second inter-

vals

Flashes at 2-second inter-

vals

Flashes at 1-second inter-

vals

Flashes at 1-second inter-

vals

Flashes at 0.25-second

intervals

Flashes at 5-second inter-

vals

Off

On

Recovery Conditions

Non-recoverable

Non-recoverable

Non-recoverable

Non-recoverable

Non-recoverable

Non-recoverable

Non-recoverable

Non-recoverable

Note:

1) If a non-recoverable error occurs, turn the power OFF immediately.

2) If a non-recoverable error occurs, please consult the dealer for repairs.

3) Paper cut error

Note:

If the cutter does not return to its home position or does not perform the initial movement,

it will result in a non-recoverable error.

4) Paper detection error

Error Description

Paper cut error

POWER Lamp

Off

ERROR Lamp

Flashes at

0.125-second

intervals

Recovery Conditions

Recovered by turning the power OFF,

eliminating the cause of the error such as

jammed paper, returning the cutter to its

home position, and turning the power ON

(see 7-3).

Error Description

Paper out error

POWER Lamp

On

ERROR Lamp

Flashes at

0.5-second inter-

vals

Recovery Conditions

Automatically recovered by loading a new

paper roll, then closing the printer cover.

– 24 –

6-3. Self-Printing

Test Printing

Turn the power ON while holding the FEED button depressed. Test printing is performed.

The version number and printer settings are printed. After the printer starts printing, release

your hand from the FEED button. After self-printing is completed, the printer will start in the

normal mode.

– 25 –

7. Preventing and Clearing Paper Jams

7-1. Preventing Paper Jams

The paper should not be touched during ejection and before it is cut. Pressing or pulling the

paper during ejection may cause a paper jam, paper cutting failure or line feed failure.

7-2. Removing Paper Jam

If a paper jam occurs, clear it as described below.

(1) Set the power switch to off to turn off power to the printer.

(2) Push the cover open lever, and open the printer cover.

If the printer cover will not open on auto cutter models, it means that the auto cutter is

not at the home position. In this case, return the auto cutter to the home position by fol-

lowing the instructions provided in section 7-3. Then open the printer cover after the pa-

per jam has been removed.

(3) Remove the jammed paper.

CAUTION

Take care not to damage the printer when removing the jammed paper.

Since it is easy to damage the thermal head in particular, take care not to touch it.

(4) Position the roll paper straight and close the printer cover gently.

Note 1: Make sure that the paper is positioned straight. If the printer cover is closed with

the paper skewed, a paper jam may result.

Note 2: Lock the printer cover by pressing down on the sides. Do not try to close it by

pressing down on the center. The cover may not lock properly.

(5) Set the power switch to on to turn on power to the printer. Make sure that the ERROR

LED is not lit.

Note: While the ERROR LED is lit, the printer will not accept any commands such as

the print command, so make sure that the printer cover is locked properly.

Caution Symbol

These labels are located near the thermal print head.

Because the thermal print head is hot immediately after printing, do not touch

it. Static electricity can damage the thermal print head. To protect the thermal

print head from static electricity, do not touch it.

This symbol is placed near the cutter.

Never touch the cutter blade, as you could injure your ngers.

This symbol is placed near the peripheral drive connector.

Do not connect this to a telephone.

This symbol label or stamp is placed near the screws securing the case or the

protective plate, which should not be opened by individuals other than service

personnel. Individuals, other than service personnel, should not remove these

screws. High voltage areas in the case can be dangerous.

– 26 –

7-3. Releasing a Locked Cutter (Auto Cutter Mode only)

If the auto cutter locks up, set the power switch to OFF to turn off the printer, and then set the

power switch to ON to turn the printer back on. A typical locked cutter will be restored when

you restart the printer.

If restarting the printer does not release the locked cutter, follow the steps below.

WARNING

Sinceworkingonthecuttermaybedangerous,besuretoturnofftheprinterrst.

(1) Set the power switch to OFF to turn off the printer.

(2) Remove the front cover to reveal the auto cutter.

(3) Remove any jammed paper.

Note: Be careful not to damage the printer while removing any jammed paper.

Since the thermal print head is particularly sensitive, be sure not to touch it.

Auto cutter

Front cover

– 27 –

(4) Insert a Philips screwdriver into the manual operation hole on the side of the cutter, and

turn it in the direction of the arrow shown on the right until the rear cover is opened.

(5) Open the printer cover, remove any jammed paper, and then reinstall the paper roll.

(6) Install the front cover, and then set the power switch to ON.

– 28 –

8. Periodical Cleaning

Printed characters may become partially unclear due to accumulated paper dust and dirt. To

prevent such a problem, paper dust collected in the paper holder and paper transport section

and on the surface of the thermal head must be removed periodically. Such cleaning is rec-

ommended to be carried out once six month or one million lines.

8-1. Cleaning the Thermal Head

To remove blackish dust collected on the surface of the thermal head, wipe it with Isopropyl

alcohol (IPA).

Note: The thermal head is easy to damage, so clean it gently with a soft cloth. Take suf-

cient care not to scratch it when cleaning it.

8-2. Cleaning the Paper Holder

Use a soft cloth to remove paper dust from the paper holder and paper transport section.

Thermal head

Paper holder

– 29 –

9. Peripheral Unit Drive Circuit

Peripheral unit drive circuit connector only connects to peripheral units such as cash drawers, etc.

Do not connect it to a telephone.

Use cables which meet the following specications.

Peripheral Drive Connector

Modular plug

Drive circuit

The recommended drive unit is shown below.

Drive Output: 24V, Max. 1.0A

TR1, TR2: Transistor 2SD1866 or equivalent

R1=10 k

Ω

R2=33 k

Ω

Reference

2SD 1866 Circuit Conguration

Pin No.

Signal

Function

I/O

name direction

1 FG Frame ground —

2 DRD1 Drive signal 1 OUT

3 +24V Drive power OUT

4 +24V Drive power OUT

5 DRD2 Drive signal 2 OUT

6 DRSNS Sense signal IN

1 6

Modular plug: MOLEX 90075-0007,

AMP641337, or BURNDY B-66-4

Wire lead

Shield

6 1

6-P Modular jack

connector

7824

F.G

TR1

M-GND

TR2

M-GND

TR3

+5V

+24V

R1

R2

6

5

4

3

2

1

L1

L2

R3

4.7kΩ

1/4W

Frame

ground

Printer side User side

D1

D2

Peripheral

unit 1

With shield

Peripheral

unit 2

Compulsion

switch

E

C

R3 R4

R3

=

3.5kΩ

R4

=

300Ω

B

– 30 –

Notes: 1. Pin 1 must be shield drain wire connected to peripheral device frame ground.

2. It is not possible to drive two drives simultaneously.

3. The peripheral drive duty must satisfy the following:

ON time / (ON time + OFF time)

0.2

4. Minimum resistance for coils L1 and L2 is 24

Ω

.

5. Absolute maximum ratings for diodes D1 and D2 (Ta = 25°C) are:

Average Rectied Current Io = 1A

6. Absolute maximum rating for transistors TR1 and TR2 (Ta = 25°C) are:

Collector current Ic = 2A

– 31 –

10. Specications

10-1. General Specications

(1) Printing method Direct line thermal printing

(2) Print speed Max. 1000 dots/sec. (125 mm/sec.)

(3) Dot density 203 dpi: 8 dots/mm (0.125 mm/dot)

(4) Printing width Max. 72 mm

(5) Roll paper Refer to chapter 5 for details on the recommended roll paper.

Paper width:79.5±0.5 mm (57.5±0.5 mm when the paper roll

holder is used)

Roll diameter: ø83 mm or less

(6) Overall dimension 142 (W)

×

204 (D)

×

132 (H) mm

(7) Weight Auto cutter model : 1.72 kg (without roll paper)

Tear bar model : 1.56 kg (without roll paper)

(8) Noise Approx. U Model

49 dB (Auto cutter model)

48 dB (Tear bar model)

PU Model

50 dB (Auto cutter model)

50 dB (Tear bar model)

Note: The noise measurements listed above were obtained ac-

cording to conditions established by this company. The

noise measurements may vary depending on the type

of paper used, type of printing, operating environment,

and power consumption mode.

– 32 –

10-4. Electrical Characteristics

10-4-1. U Model

(1) Input Voltage 100 to 240 V AC, 50/60 Hz

(2) Current Consumption Operating: Approx. 40 W (at ASCII printing)

Stand-by: Approx. 3 W

10-2. Auto Cutter Specications

(1) Cutting frequency Max. 20 cuts per minute

(2) Thickness of paper 65~85 µm

10-3. Interface

(1) Specications USB 2.0 full speed

Printer class and vendor class compatible

(2) Connector

U Model Type B

PU Moedl Type B and PoweredUSB connector

Type B connector:

DUSB-BRA42-T11(D2)-FA (manufacturer: DDK)

Pin No. Signal name Function

1 VBUS USB Power pin (+5V DC)

2 D - Serial Date -

3 D + Serial Date +

4 GND Signal ground

PoweredUSB connector:

69913-104LF (manufacturer: FCI)

Pin No. Signal name Function

1 F-GND Frame ground

2 +24V +24V DC

3 GND Signal ground

4 D + Serial Date +

5 D - Serial Date -

6 VBUS USB Power pin (+5V DC)

7 +24V +24V DC

8 F-GND Frame ground

3 4

2 1

1

8

– 33 –

10-4-2. PU Model (AC adapter)

(1) Input: 100 to 240V AC, 50/60 Hz

(2) Output: DC 24V ± 5%

(3) Current Consumption (DC 24 V at room temperature)

Low-power consumption mode:

Stand-by: Approx. 0.1A

Mean: Approx. 1.0A (at ASCII continuous printing)

Peak: Approx. 5.0A

(at print duty 100%, for 10 seconds or less)

Standard mode:

Stand-by: Approx. 0.1A

Mean: Approx. 1.4A (at ASCII continuous printing)

Peak: Approx. 10.0A

(at print duty 100%, for 10 seconds or less)

To switch between the standard and low-power consumption modes, refer to chapter 11

for details on the DIP switch settings.

Notes: There is a danger that there will be a large incoming current when turning the

printer back on after turning it off. Therefore, wait at least 5 seconds before turn-

ing the printer back on.

(4) Power Connector

Notes:

• When using a printer power supply other than the optional AC adapter (PS60A-24A

series), be sure that the following cautions are observed.

• Use a power supply of DC 24 V ± 5% and more than 2.0 A (5.0 A Load 10 sec. Min.)

with SELV output and LPS or Class 2 output approved by IEC60950.

• Be careful about installing the printer in an area where there is noise. Take the appro-

priate measures to protect against electrostatic AC line noise, etc.

<Viewed from Connector Surface>

Pin No. Function

1 Drive power (24V)

2 Signal GND

3 N.C.

Shell Frame ground

1

2

3

– 34 –

10-4-3. PU Model (PoweredUSB cable)

When using the PoweredUSB cable, DC 24 V must be supplied to the printer from the sys-

tem. Use a power supply for the printer that meets the following requirements.

Power Requirements

(1) Output: DC 24V ± 5%

(2) Current Consumption (DC 24 V at room temperature)

Low-power consumption mode:

Stand-by: Approx. 0.1A

Mean: Approx. 1.0A (at ASCII continuous printing)

Peak: Approx. 5.0A

(at print duty 100%, for 10 seconds or less)

Standard mode:

Stand-by: Approx. 0.1A

Mean: Approx. 1.4A (at ASCII continuous printing)

Peak: Approx. 10.0A

(at print duty 100%, for 10 seconds or less)

To switch between the standard and low-power consumption modes, refer to chapter 11

for details on the DIP switch settings.

Notes: There is a danger that there will be a large incoming current when turning the

printer back on after turning it off. Therefore, wait at least 5 seconds before turn-

ing the printer back on.

– 35 –

10-5. Environmental Requirements

(1) Operating

Temperature 5°C to 45°C

Humidity 10% to 90% RH (without condensation)

(2) Transport/storage (except for paper)

Temperature -20°C to 60°C

Humidity 10% to 90% RH (without condensation)

(%RH)

90

80

60

40

20

10

0 10 20

Operating environment

range

Relative humidity

Operating temperature and humidity range

30 40 50

– 36 –

10-6. Reliability

1) Life Mechanical: 20 million lines

Head: 100 million pulses, 100 km (±15% max. average head resist-

ance uctuation)

For 2-color printing, 50 million pulses, 50 km (±15% max. av-

erage head resistance uctuation)

Auto cutter: 1 million cuttings (provided the paper thickness is between 65

and 85 µm)

<Conditions>

Average printing ratio: 12.5%

Recommended thermal paper: 65 µm

2) MCBF: 60 million lines

The Mean Cycle Between Failure (MCBF) is dened to be the overall failure cycle,

which includes random or wear failures that occur until the printer reaches its mechani-

cal life of 20 million lines.

* As the mechanical remains at 20 million lines, the MCBF of 60 million lines does not in-

dicate its useful life.

3) Auto Cutter (Life)

1 million cuttings (provided the paper thickness is between 65 and 85 µm)

* All the reliability values indicated above are based on the use of the recommended ther-

mal paper. No reliability can be guaranteed for the use of non-recommended thermal pa-

per.

– 37 –

11. DIP Switch Settings

There are DIP switches located on the bottom of the PU model printers and various settings

can be performed as shown in the following table.

When changing the settings, use the following procedure.

Note: For U model printers, the DIP switch settings do not need to be performed.

(1) Turn the printer off and disconnect the power cable plug from the AC outlet.

(2) Remove the screw, and then remove the DIP switch cover on the bottom of the printer.

(3) Use a tool with a narrow tip to change the DIP switch settings.

(4) Install the DIP switch cover and secure it with the screw.

Note: The new settings will take effect after the printer is turned on.

DIP switch 1

Switch 1-1 Power consumption mode

OFF Standard mode

ON Low-power consumption mode (Default setting)

Always set DIP switches 1-2 and 1-3 to ON and DIP switch 1-4 to OFF.

1 2 3 4

When the printer is shipped, DIP switch 1-4 is set to

OFF; all of the other switches are set to ON.

[PU model]

DIP switch 1

OFF

ON

SPECIAL PRODUCTS DIVISION

STAR MICRONICS CO., LTD.

536 Nanatsushinya, Shimizu-ku, Shizuoka,

424-0066 Japan

Tel: (int+81)-54-347-0112, Fax: (int+81)-54-347-0409

Please access the following URL

http://www.star-m.jp/eng/dl/dl02.htm

for the latest revision of the manual.

OVERSEAS SUBSIDIARY COMPANIES

STAR MICRONICS AMERICA, INC.

1150 King Georges Post Road, Edison, NJ 08837-3729 U.S.A.

Tel: (int+1)-732-623-5555, Fax: (int+1)-732-623-5590

STAR MICRONICS EUROPE LTD.

Star House, Peregrine Business Park, Gomm Road,

High Wycombe, Bucks, HP13 7DL, U.K.

Tel: (int+44)-1494-471111, Fax: (int+44)-1494-473333