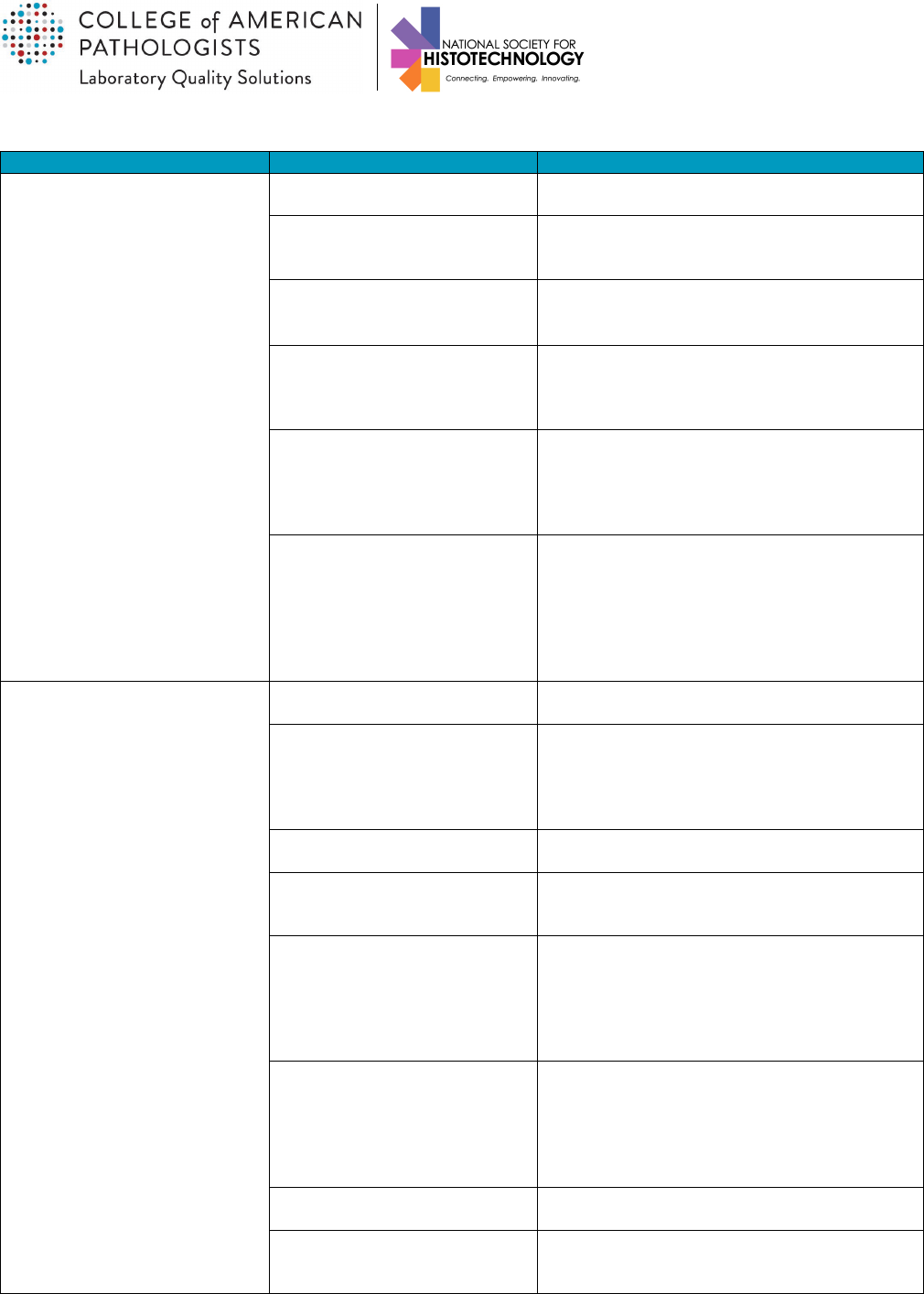

H&E Troubleshooting Table

Page 1 of 7

Problem

Cause

Solution

1. Nuclei not crisp, “smudgy”

nuclei, nuclear bubbling or no

distinct chromatin pattern

seen. There is no variation in

the nuclear chromatin patterns

among cells, and there is no

variation in chromatin staining

within one nucleus.

a) Fixation is incomplete.

b) Fixation delayed (time to

fixation was inadequate).

c) Quality of fixative was poor due

to solution

exhaustion/overused.

i) Allow tissues to fix for a longer time.

ii) Tissue should be placed in fixative (formalin)

immediately.

iii) Document time in fixative to assure adequate

fixation.

iv) Exchange the fixative in the containers

(grossing table and tissue processor) at

regular intervals.

b) Water is not completely

removed during the processing

dehydration.

i) Ensure the dehydration is sufficient by

reviewing processing schedule.

ii) Ensure that processing solutions are rotated

and/or exchanged on a schedule to prevent

solution exhaustion.

c) Slides were exposed to

excessive heat during

processing or drying.

i) Ensure that tissues are not exposed to high

temperatures, and if increased temperature is

required that it be as low as possible and

exposure time is limited.

ii) Assess whether paraffin baths provide radiant

heat to the retort, causing temperature to be

increased during dehydration and clearing

steps. Adjust exposure times to counter

increased heat.

iii) Remove excess water from cut slides by

standing slides on end or edge to allow water

to drain thoroughly before drying. Dry slides at

as low a temperature as possible.

2. Three distinct shades of eosin

not seen.

a) Fixation inadequate.

i) Ensure adequate fixation by prolonging the time

allowed.

ii) Exchange the fixative in the containers

(grossing table and tissue processor) at regular

intervals.

b) Improper processing occurred.

i) Ensure that proper processing occurs, by

validating each step for completeness.

c) There is poor differentiation of

the eosin.

i) Ensure good differentiation of the eosin.

Differentiation of eosin occurs best in 70%

alcohol solutions and to a lesser extent in

higher grade alcohols. Therefore, adding 70%

alcohol to the dehydration series or increasing

the time in the 70% alcohol will aid in

differentiation.

ii) Ensure that the 70% or 95% alcohol used in

eosin differentiation is changed at regular

intervals.

d) Eosin solution is not at the

correct pH. The correct pH for

eosin stain is pH 4.0-4.5.

Check manufacturer’s SDS for

pH for commercially prepared

stains.

i) Exchange eosin solution on stainer with fresh

eosin or adjust by adding acetic acid.

ii) Ensure that slides are well rinsed in water after

“bluing” to avoid carry over of alkaline solutions

into the eosin stain.

H&E Troubleshooting Table

Page 2 of 7

Problem

Cause

Solution

3. Poor contrast between the

nuclear stain (hematoxylin)

and the cytoplasmic stain

(eosin).

a) The nuclear stain is too dark.

i) Decrease the intensity of the hematoxylin

staining by decreasing the time in the

hematoxylin solution or increasing the time in

the nuclear differentiating solution.

ii) Check the pH of the hematoxylin daily to

maintain an optimum acidic solution (pH 2.5-

2.9). Adjust the pH using the acid used in the

original formulation.

b) Nuclear stain is too pale

compared to the cytoplasmic

stain.

i) Increase the intensity of the hematoxylin stain

by:

• Increasing the time in the hematoxylin stain

• Decreasing the time in the nuclear

differentiating solution

• Change to a stronger hematoxylin

formulation

ii) The pH of the water used to rinse slides after

hematoxylin staining must be neutral

• Acidic rinse water will act as a differentiator,

removing hematoxylin

• Iron in tap water can act as a hematoxylin

differentiator

• Water pH can be affected by agricultural

runoff or other contaminants from old

plumbing lines.

iii) The pH of running tap water rinses can be

controlled by placing ionization filters in the

water line or by connecting directly to a de-

ionized or distilled water source.

c) The cytoplasmic stain is too

dark compared to the nuclear

stain.

i) Decrease the intensity of the eosin stain by:

• Decreasing the time in the eosin stain

• Diluting the eosin stain

• Change the eosin stain formulation

• Adjusting concentration of phloxine dye, if

used

• Allowing more time in the 70% or 95%

dehydrating alcohols

d) The cytoplasmic stain is too

light compared to the nuclear

stain.

i) Increase the intensity of the eosin stain by:

• Allowing a longer time in the eosin stain

• Decreasing the time in the 70% or 95%

dehydrating alcohols

• Ensuring the pH of the eosin is between 4.0

and 4.5 and adjust if required

•

Change to an eosin-phloxine formulation

H&E Troubleshooting Table

Page 3 of 7

Problem

Cause

Solution

4. Cytoplasmic stain

(eosin) is too dark; the

cytoplasmic stain is so intense

that the differentiation between

collagen, smooth muscle and

red cells is lost.

a) Staining time in the eosin is

too long

i) Decrease the staining time in the eosin solution.

b) There is inadequate eosin

differentiation in the alcohols

that follow the eosin stain.

i) Increase the differentiating time in the 70% or

95% dehydrating alcohol.

c) Aqueous eosin formulations

stain tissues darker than

alcohol-based stains.

i) Switch to an alcohol-based eosin which is easier

to differentiate in the graded alcohols used for

dehydration.

d) The alcohol rinse used for

differentiation is not

performed properly after eosin

staining.

i) Change the first alcohol rinse from 100% to 95%

alcohol or from 95% to 70% alcohol.

e) Eosin may be too

concentrated, especially if

phloxine is present.

i) If phloxine is present, decrease the

concentration or change to an eosin only

formulation.

ii) Dilute the eosin with diluted alcohol (70%, 95%)

that is used in the original formulation.

f) Isopropyl alcohol was used as

the dehydrating alcohols;

isopropyl alcohol does not

differentiate eosin in the same

manner as ethyl alcohol.

i) Change the type of dehydrating alcohol used.

ii) Increase the time in the isopropyl alcohol

rinses.

iii) Use a diluted isopropyl alcohol (e.g., 95% or

80%) as the first alcohol following the eosin in

dehydration, follow with the standard 99%

isopropyl alcohols.

5. Cytoplasmic stain (eosin) is too

light. The cytoplasmic stain is

so pale that the differentiation

between collagen, smooth

muscle and red cells is lost.

a) The eosin solution is

overused/exhausted.

i) Replace the current eosin stain with a fresh

eosin stain.

b) The eosin has passed the

expiry date.

i) Replace eosin with fresh (in date) solution.

ii) Rotate commercially prepared supplies to

ensure oldest lot number is used first.

iii) Prepare only sufficient volume of eosin to be

used with established stabile date range.

c) The staining time in the eosin

stain is too short.

i) Increase the staining time in eosin solution.

d) The pH of the eosin staining

solution is greater than 4.5.

i) Check the pH of the staining solution; it should

be between 4.0 and 4.5. If necessary, adjust

the pH with acetic acid.

e) Eosin stain formulation is not

correct (eosin dye

concentration low)

i) Adjust concentration of eosin dye in staining

solution and re-validate staining method.

ii) Change eosin formula to include phloxine dye

and re-validate staining method.

iii) Decrease alcohol dilution (add more water) in

the staining solution

f) The bluing solution (pH 8) is

not completely washed out of

the section or off the glass

slide or staining rack before

the slides are transferred to

the eosin solution.

i) Increase rinse time in running water (or more

changes) after bluing solution. Carryover of the

bluing reagent can raise the pH of the eosin.

Eosin with a pH 5 stains lighter than eosin pH

4.5.

g) Differentiation in diluted

alcohols is prolonged.

i) Decrease the time in the

differentiation/dehydrating alcohols.

h) The alcohol rinse after the

eosin stain is incorrectly

performed.

i) Validate that correct staining procedure is being

followed.

H&E Troubleshooting Table

Page 4 of 7

Problem

Cause

Solution

6. Nuclear stain too dark, the

nuclear stain is so dark that

the chromatin pattern is lost,

and some non-nuclear

elements show hematoxylin

staining.

a) The hematoxylin solution is too

strong due to formulation.

i) Replace hematoxylin solution with weaker

formulation (ie,, replace Gills III with Gills II).

b) Staining time in the

hematoxylin stain is too long.

i) Adjust staining protocol, decreasing the staining

time in hematoxylin.

c) There is inadequate

differentiation of the

hematoxylin stain.

i) Adjust staining protocol, increasing time in the

differentiation solution.

ii) Change formulation of differentiation solution

• Change concentration of acid

Decrease alcohol concentration (e.g., change

from 95% alcohol to 70% alcohol)

7. Nuclear stain too light, the

nuclear stain is so light that

well defined chromatin

patterns cannot be seen.

a) Incomplete deparaffinization.

i) Increase the number of changes of xylene, or

xylene substitute used for removal of paraffin.

ii) Increase the amount of time in each xylene, or

xylene substitute, used for paraffin removal.

b) The hematoxylin is

overused/exhausted or used

beyond its shelf life.

i) Replace hematoxylin with fresh (in date)

solution.

ii) Rotate commercially prepared supplies to

ensure oldest lot number is used first; use by

expiration date provided by manufacturer.

iii) Prepare only sufficient volume of hematoxylin

to be used with established stabile date range.

iv) Prevent overoxidation of hematoxylin solution

by storing in a tightly closed container away

from direct sunlight. Store in a dark container.

Store at room temperature.

c) The pH of the hematoxylin is

incorrect. The correct pH for

hematoxylin solution is pH 2.4-

2.9. Check manufacturer’s

SDS for pH for commercially

prepared stains.

i) Check the pH of the hematoxylin solution. If

necessary, adjust the pH using the acid used

in the original formulation.

d) The hematoxylin is diluted by

carryover from a previous

water rinse.

i) Change to fresh hematoxylin solution. Establish

a regular change schedule for reagents.

e) Sections are over

differentiated.

i) Decrease the time in the differentiating solution.

ii) Decrease the acid concentration of the

differentiation solution.

iii) Increase the alcohol content of the

differentiating solution from 70% to 95%

alcohol.

f) Staining time in hematoxylin

solution is too short.

i) Increase the time in hematoxylin solution.

H&E Troubleshooting Table

Page 5 of 7

Problem

Cause

Solution

7. (Cont’d)

g) Additives/contaminants are

present in tap water rinses

(before or after the staining).

i) The pH of the water used to rinse slides after

hematoxylin staining must be neutral Acidic

rinse water will act as a differentiator removing

hematoxylin

ii) Iron in tap water can act as a hematoxylin

differentiator

iii) Water pH can be affected by agricultural runoff

or other contaminants from old plumbing lines.

The pH and contaminants of running tap water

rinses can be controlled by placing ionization

filters in the water line or by connecting directly to

a de-ionized or distilled water source.

h) Poor fixation and or

processing, resulting in tissues

that are unable to bind the

stain.

i) Ensure that tissue blocks are well fixed prior to

processing and are well dehydrated, cleared

and paraffin infiltrated during processing

protocol.

i) Section too thin.

i) Thin sections result in less tissue binding sites

for hematoxylin to attach. Increase staining

time may help only to a certain degree. Recut

thicker sections.

8. Uneven hematoxylin or eosin

staining; the stain varies in

intensity in different areas of

the section.

a) The section may be thick

and/or thin; chatters or

venetian blind effect.

i) Recut the section, ensuring that the section is

of uniform thickness.

b) Some solutions are not high

enough to cover entire

section, resulting in a distinct

line across the section.

i) Ensure that all solutions are of sufficient volume

to completely cover the tissue sections,

especially when slide rack is only partially

filled.

c) Nuclear differentiation solution

(acid alcohol) or bluing

solution volume is higher than

wash water levels. Acid

alcohol and/or bluing reagent

become trapped between

slides/in slide racks and not

washed away by water; they

then drip down the slide

causing vertical lines to

appear on the slide where

staining intensity is affected.

i) Ensure that water wash levels are higher than

acid alcohol and bluing solution levels.

d) The water rinse was not

adequate after hematoxylin

staining to remove excess

hematoxylin.

i) Increase the time and/or fluid levels of water

rinses.

e) The water rinse after acid

alcohol was not adequate to

stop differentiation of

hematoxylin.

i) Increase the time and/or fluid levels of water

rinse after acid alcohol.

H&E Troubleshooting Table

Page 6 of 7

Problem

Cause

Solution

9. Red brown nuclei. The nuclear

stain has a distinct red brown

or reddish hue, often seen

throughout the entire slide.

a) The sections have not been

sufficiently blued.

i) Increase the amount of time the sections remain

in the bluing solution.

ii) Ensure the pH of bluing solution is minimally pH

7-8.

iii) Increase water rinsing time post hematoxylin

differentiation.

b) The hematoxylin is breaking

down due to over oxidation of

the hematein.

i) Change to a fresh solution of hematoxylin.

ii) Check expiry date of hematoxylin solution.

10. Dark precipitate scattered

throughout the section; blue-

black or purple precipitate is

present on parts of the

section.

a) Deteriorated hematoxylin.

Hematoxylin is used beyond

the expiry date or damaged

from improper storage

conditions.

i) Change to a fresh solution of hematoxylin.

ii) Ensure proper storage of hematoxylin solutions

according to manufacturer’s guidelines.

iii) Check with supplier that hematoxylin was stored

correctly during shipping. Excessive heat or

freezing can cause solution to decompose.

b) Some hematoxylin

formulations (e.g., Harris

hematoxylin) form a metallic

sheen on the surface of the

solution when exposed to air.

This metallic sheen transfers

or adheres to the surface of

slide and the tissue section.

i) Monitor the hematoxylin solution throughout the

day for the appearance of a metallic sheen

(hematein). If this is observed, replace or filter

the hematoxylin, ensuring that the solution

container is clean and free of deposits before

reuse.

11. Sections with an overall hazy

appearance or eosin

bleeding throughout the

section, the tissue appears

hazy or out of focus when

examined microscopically.

a) Dehydrating and clearing

solutions are contaminated

with water from previous

solutions or humidity.

i) Design and implement a standardized, routine,

solution change schedule for alcohols and

xylene that minimizes humidity contamination or

helps keep carry over from prior solutions to a

minimum.

b) Sections were not adequately

dehydrated after eosin

staining.

i) Use a minimum of three changes of anhydrous

alcohol at the end of the staining series

ii) Increase the amount of time per station, for each

anhydrous alcohol, at the end of the staining

series.

iii) Establish a schedule for regularly changing the

anhydrous alcohols used for dehydration.

12. Mucus staining with

hematoxylin.

a) Hematoxylin formulations differ

in their abilities to stain acid

mucin. Gill hematoxylin

formulations will stain

specifically acid mucins. Harris

formulations due to their

excess alum will not stain acid

mucins.

i) Depending on the preference of the pathologist

change hematoxylin formulation being used.

ii) For proprietary formulations check with the

manufacturer for staining characteristics of acid

mucin.

iii) Acid differentiation of acid mucins staining by

Gill hematoxylin will decolorize both the mucin

and the nuclei.

H&E Troubleshooting Table

Page 7 of 7

Problem

Cause

Solution

13. Mounting artifact – air is

under the coverslip and the

image of the tissue is

obscured or mounting media

is on top of the coverslip,

making focusing on some

areas of the tissue difficult.

a) The mounting media has

retracted from the edges of the

coverslip.

i) Gently remove the coverslip by exposing the

slide to xylene or xylene substitute to soften and

remove mounting media. Expose section to

fresh solutions of clearant and remount a new

coverslip

ii) Ensure the mounting media is not too thin.

Xylene or toluene is used as a diluent in the

mounting media and as it evaporates the resin

can retract from the edges of the slide.

iii) Ensure that automated or manual process is not

adding or retaining too much xylene on slide

surface to thin mounting media.

b) The mounting media has not

spread to the edges of the

coverslip.

i) Gently remove the coverslip by exposing the

slide to xylene or xylene substitute to soften and

remove mounting media. Expose section to

fresh solutions of clearant and remount a new

coverslip.

ii) Ensure that automated or manual process is

applying sufficient mounting media to spread

across entire surface of coverslip. The volume

required must be adjusted to the size of the

coverslip used.

iii) Ensure that the surface of the slide holds

sufficient xylene to assist with the spread of the

mounting media.

c) Air bubbles are trapped under

the coverslip.

i) Gently remove the coverslip by exposing the

slide to xylene or xylene substitute to soften and

remove mounting media. E pose section to fresh

solutions of clearant and remount a new

coverslip.

ii) Avoid mixing or shaking mounting media when

adding to automated or manual dispensing

bottle. If this occurs, wait and allow bubbles to

rise to the surface and dissipate.

d) There is mounting media on the

top of the coverslip.

i) Gently remove the coverslip by exposing the

slide to xylene or xylene substitute to soften

and remove mounting media. Expose section

to fresh solutions of clearant and remount a

new coverslip.

14. Brown granular deposit,

similar in appearance to

formalin pigment, is seen

throughout the section. The

nuclei appear glossy, black,

and refractile with brown

stippling.

a) The tissue section has dried out

before the coverslip was

applied.

i) Gently remove the coverslip by exposing the

slide to xylene or xylene substitute to soften and

remove mounting media. Expose section to

fresh solutions of clearant and remount a new

coverslip.