Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Supersedes Publication# BATCH-UM004B-EN-D - May 2022

User Manual

Original Instructions

FactoryTalk Batch

Equipment Editor User

Manual

FactoryTalk Batch Equipment Editor User Manual

2 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Important User Information

Read this document and the documents listed in the additional resources section about installation, configuration, and

operation of this equipment before you install, configure, operate, or maintain this product. Users are required to

familiarize themselves with installation and wiring instructions in addition to requirements of all applicable codes, laws,

and standards.

Activities including installation, adjustments, putting into service, use, assembly, disassembly, and maintenance are

required to be carried out by suitably trained personnel in accordance with applicable code of practice.

If this equipment is used in a manner not specified by the manufacturer, the protection provided by the equipment may

be impaired.

In no event will Rockwell Automation, Inc. be responsible or liable for indirect or consequential damages resulting from

the use or application of this equipment.

The examples and diagrams in this manual are included solely for illustrative purposes. Because of the many variables

and requirements associated with any particular installation, Rockwell Automation, Inc. cannot assume responsibility or

liability for actual use based on the examples and diagrams.

No patent liability is assumed by Rockwell Automation, Inc. with respect to use of information, circuits, equipment, or

software described in this manual.

Reproduction of the contents of this manual, in whole or in part, without written permission of Rockwell Automation, Inc.,

is prohibited.

Throughout this manual, when necessary, we use notes to make you aware of safety considerations.

WARNING:

Identifies information about practices or circumstances that can cause an explosion in a hazardous environment, which may lead to

personal injury or death, property damage, or economic loss.

ATTENTION:

Identifies information about practices or circumstances that can lead to personal injury or death, property damage, or economic loss.

Attentions help you identify a hazard, avoid a hazard, and recognize the consequence.

IMPORTANT

Identifies information that is critical for successful application and understanding of the product.

Labels may also be on or inside the equipment to provide specific precautions.

SHOCK HAZARD: Labels may be on or inside the equipment, for example, a drive or motor, to alert people that dangerous voltage may be present.

BURN HAZARD:

Labels may be on or inside the equipment, for example, a drive or motor, to alert people that surfaces may reach dangerous

temperatures.

ARC FLASH HAZARD: Labels may be on or inside the equipment, for example, a motor control center, to alert people to potential Arc Flash. Arc Flash will

cause severe injury or death. Wear proper Personal Protective Equipment (PPE). Follow ALL Regulatory requirements for safe work practices and for

Personal Protective Equipment (PPE).

Rockwell Automation recognizes that some of the terms that are currently used in our industry and in this publication are

not in alignment with the movement toward inclusive language in technology. We are proactively collaborating with

industry peers to find alternatives to such terms and making changes to our products and content. Please excuse the

use of such terms in our content while we implement these changes.

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 3

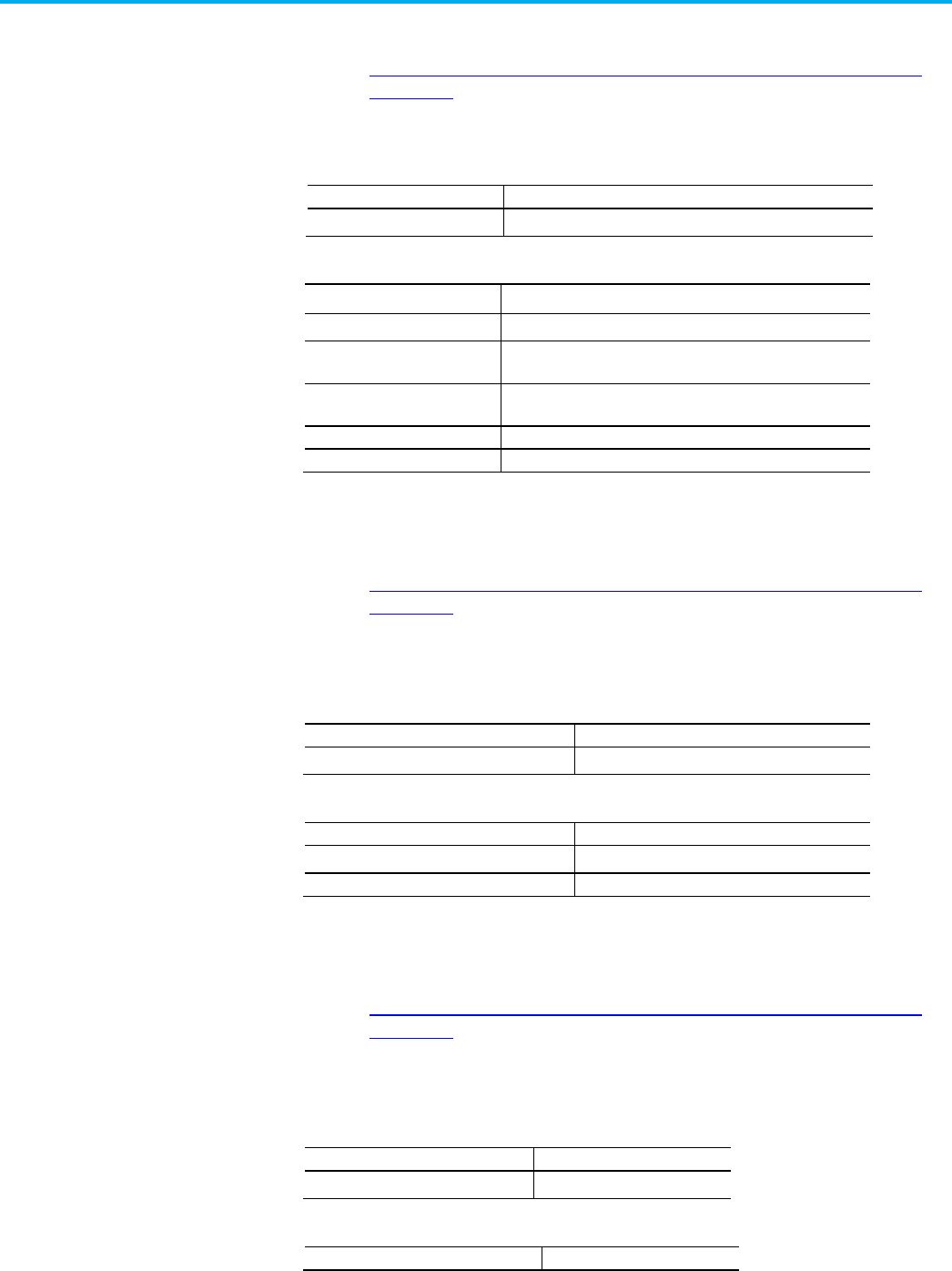

Summary of changes in Equipment Editor

This publication contains the following new or updated information. This

list includes substantive updates only and is not intended to reflect all

changes. The identified change will fall into one of these categories:

• New feature

• Enhanced feature

• Functional change

• Anomaly fix

• Usability improvement

• Clarification

Topic

Reason for change

Area models on page 23

Enhanced feature

Material capability removal on page 27

New feature

Create Phase Class dialog box - General tab on page 139

Enhanced feature

Edit Phase dialog box - General tab on page 163

Enhanced feature

Edit Operation Sequence dialog box - General tab on page

190

Enhanced feature

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 5

Table of Contents

About the Equipment Editor manual ........................................... 13

Legal Notices .............................................................................. 13

Additional resources ................................................................... 14

Chapter 1

FactoryTalk Batch Equipment Editor security ............................. 18

Open FactoryTalk Batch Equipment Editor ............................ 18

FactoryTalk Batch Equipment Editor interface ............................ 19

Menu bar ............................................................................... 20

Toolbar .................................................................................. 20

Chapter 2

Create an area model ................................................................. 24

Open an area model ................................................................... 25

Area models migration .......................................................... 26

Area models and FactoryTalk Batch Material Manager ........ 26

Material database changes .............................................. 26

Material database is unavailable ..................................... 27

Material capability removal .............................................. 27

Verify and deploy area model ..................................................... 28

Chapter 3

XML area models ........................................................................ 31

Import an XML area model ..................................................... 31

Import enumerations ........................................................ 32

Import system phase classes .......................................... 33

Export an area model to XML ............................................... 34

Convert XML to binary from command line ........................... 34

Chapter 4

System enumeration sets ........................................................... 37

Create enumeration sets ............................................................. 38

Add enumeration members ................................................... 39

Edit enumerations and sets ........................................................ 40

Delete enumerations and sets .............................................. 40

Chapter 5

Parameters and reports in recipes .............................................. 43

Parameters example .............................................................. 43

Parameters, reports, and phase tags .......................................... 44

Overview of tags for phases .................................................. 44

Phase tags ............................................................................ 45

Batch parameters and reports .................................................... 46

Phase class parameters ........................................................ 46

Phase class reports............................................................... 46

Material parameters ................................................................... 47

Types of containers ............................................................... 47

Summary of changes in

Equipment Editor

Preface

FactoryTalk Batch Equipment

Editor

Area models

Import and export area models

Enumerations overview

Parameters and reports with

FactoryTalk Batch

Table of Contents

6 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Default material parameters .................................................. 47

Scale parameters ....................................................................... 48

Verification method for parameter deviations ............................. 49

Control strategies overview ........................................................ 49

Control strategies example ................................................... 49

Implement control strategies ................................................. 50

Parameter and report subsets .................................................... 51

Phase class with different subsets ........................................ 51

Download parameter requests .............................................. 52

Upload report requests .......................................................... 53

Automatic Upload/Download ...................................................... 53

Control strategy with parameter subset ...................................... 54

Chapter 6

Types of electronic signatures .................................................... 57

How electronic signatures work .................................................. 57

Signature template ..................................................................... 61

Edit signature templates dialog box ...................................... 61

Add a signature template ...................................................... 62

Set signature template signoffs ............................................. 63

Set security permissions for a signoff .............................. 65

Remove signoff permissions ............................................ 67

Delete a signature template .................................................. 67

Modify a signature template .................................................. 68

Command verification policies .................................................... 69

Add electronic signatures to commands ............................... 69

Edit command verification policies ................................... 70

Change a command verification policy.................................. 70

Remove signature requirement commands .......................... 70

Chapter 7

Recipe approval tasks ................................................................. 73

Configure recipe approval steps ................................................. 74

Recipe Approvals Configuration settings ............................... 76

Edit a recipe approval ................................................................. 77

Disable recipe approval .............................................................. 77

Chapter 8

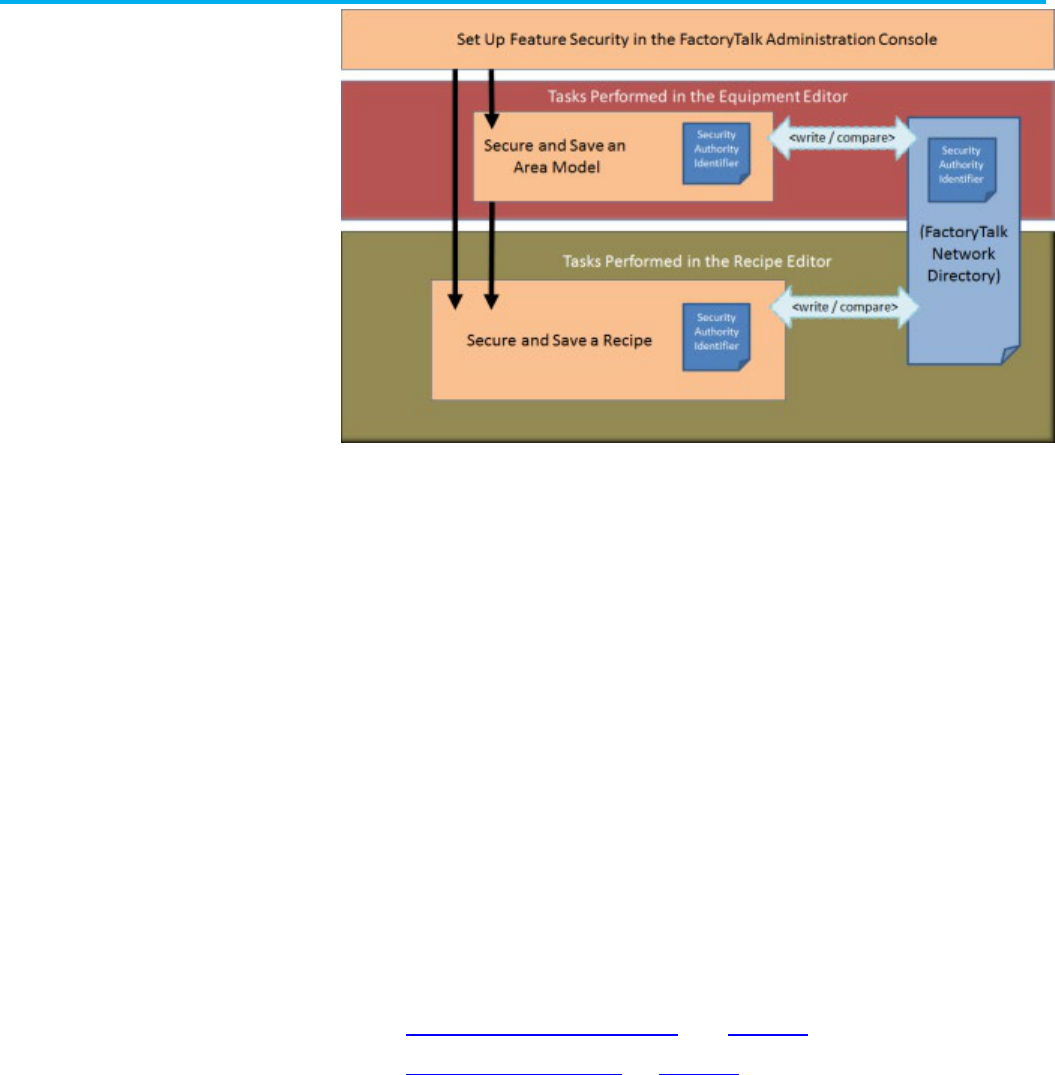

Security authority configuration ................................................... 79

Secure an area model ................................................................. 80

Chapter 9

Area model data servers ............................................................. 83

Data Servers dialog box ......................................................... 84

Edit a data server .................................................................. 84

Delete a data server .............................................................. 85

Assign data servers............................................................... 86

OPC data servers ....................................................................... 86

Electronic signatures

Recipe approval process

overview

Security authority overview

Data servers overview

Table of Contents

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 7

Add an OPC data server ....................................................... 87

FactoryTalk Linx FactoryTalk Live Data server .......................... 88

Add a data server .................................................................. 88

FactoryTalk Linx server path ................................................. 90

Configure the FactoryTalk Linx server path .......................... 90

Logix5000 CIP data server ......................................................... 91

Add a Logix5000 CIP data server ......................................... 91

Edit a Logix5000 CIP data server ......................................... 92

Assign a Logix5000 CIP data server to a phase or sequence

.............................................................................................. 93

Chapter 10

Manage Diagnostics page system elements ............................... 95

Define shared resources ............................................................. 96

Set general information for resources ................................... 96

Configure arbitration information ........................................... 97

Set cross invocation information ........................................... 98

Configure hyperlink information ............................................ 98

Chapter 11

Unit binding expression builder ................................................... 99

Expression operators ........................................................... 100

Supported data types .......................................................... 101

Operands .................................................................................. 102

Expression validation .......................................................... 102

Create global binding requirements .......................................... 102

Edit binding requirements ................................................... 103

Delete binding requirements ............................................... 104

Chapter 12

Create a process cell class ....................................................... 105

Edit a process cell class ............................................................ 105

Create process cell instances ................................................... 106

Configure a process cell instance ....................................... 106

Set general data for a process cell ...................................... 107

General tab of Edit process cell ..................................... 107

Set arbitration data for process cell ..................................... 107

Arbitration tab of Edit Process Cell ................................ 108

Set cross invocation data for process cell ........................... 108

Cross Invocation tab properties ..................................... 109

Configure hyperlink data for a process cell ......................... 109

Edit process cell dialog box - Hyperlink tab ................... 110

Remove a process cell instance ......................................... 110

Verify icon paths ....................................................................... 111

Unique icons ............................................................................. 111

Chapter 13

Create a unit class .................................................................... 113

Resources overview

Global binding requirements

Process cell overview

Unit overview

Table of Contents

8 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Edit a unit class ........................................................................ 114

Create a unit instance .............................................................. 115

Unit instance configuration ....................................................... 115

Open the Edit Unit dialog box ............................................. 115

Configure the general data for a unit ................................... 116

Edit Unit dialog box - General tab .................................. 116

Configure unit attribute tags data ........................................ 117

Edit Unit dialog box - Attribute Tags tab ........................ 117

Configure arbitration data for a unit ..................................... 118

Edit Unit dialog box - Arbitration tab .............................. 119

Configure cross invocation data for a unit ........................... 119

Edit Unit dialog box - Cross Invocation tab .................... 120

Configure hyperlink data for a unit ...................................... 120

Edit Unit dialog box - Hyperlink tab ................................ 121

Remove a unit instance ............................................................ 121

Link unit instances .................................................................... 121

Share units ............................................................................... 122

Chapter 14

Unit attribute tags ...................................................................... 125

Add a unit attribute ............................................................... 126

Edit a unit attribute .............................................................. 127

Delete a unit attribute .......................................................... 127

Create a unit attribute tag .................................................... 127

Unit Attribute Tags dialog box ........................................ 129

Phase tags ............................................................................... 129

Edit tags from the menu ...................................................... 130

Default equipment names ................................................... 131

Set all tag items to default name and access path ........ 131

Global unit attribute .................................................................. 132

Create a global unit attribute ............................................... 132

Edit a global unit attribute .................................................... 134

Delete a global unit attribute ............................................... 134

Remove a global unit attribute ............................................ 135

Chapter 15

Tags .......................................................................................... 137

Create and configure phase classes ......................................... 138

Configure phase class general attributes ............................ 138

Create Phase Class dialog box - General tab ................ 139

Configure phase class parameters ..................................... 140

Create Phase Class dialog box - Parameters tab .......... 142

Configure phase class reports ............................................ 144

Create Phase Class dialog box - Reports tab ................ 145

Select context IDs ............................................................... 147

Configure phase class messages ....................................... 148

Create Phase Class dialog box - Messages tab ............ 149

Configure phase class control strategies ............................ 149

Create Phase Class dialog box - Control Strategy tab ... 150

Tags overview

Phase class overview

Table of Contents

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 9

Verification policies ................................................................... 151

How verification policies work ............................................. 151

Configure parameters and reports verification policy .......... 152

Verification Policies dialog box ...................................... 154

How verification policies work with control strategies .......... 156

How editing target parameters affects report verification

policies ................................................................................ 156

Material-enabled phase classes ............................................... 157

Standard phase class with matching parameter and report

names ................................................................................. 157

Standard phase class with control strategies configured .... 158

Disable material on a material-enabled phase class ................ 158

Duplicate a phase class ........................................................... 158

Copy a phase class ............................................................. 159

Cut and paste a phase class ............................................... 159

Chapter 16

Create a phase ......................................................................... 161

Configure the general data for a phase ................................ 162

Edit Phase dialog box - General tab .............................. 163

Configure the tag data for a phase ...................................... 164

Edit Phase dialog box - Tag tab ..................................... 165

Phase tag ...................................................................... 165

Set tag items to the default addresses ........................... 168

Configure the arbitration data for a phase ........................... 169

Edit Phase dialog box - Arbitration tab ........................... 169

Configure cross invocation data for a phase ....................... 170

Edit Phase dialog box - Cross Invocation tab ................ 170

Configure hyperlink data for a phase .................................. 171

Edit Phase dialog box - Hyperlink tab ............................ 171

Configure container data ..................................................... 171

Edit Phase dialog box - Containers tab .......................... 172

Parameter limit tags ................................................................. 173

Enable parameter limit tags ................................................ 173

Edit Phase dialog box - Parameter Limit Tags tab ......... 173

Map parameter tags to parameter limit tags ........................ 174

Report limit tags ....................................................................... 175

Edit Phase dialog box - Report Limit Tags tab .................... 175

Enable report limit tags ....................................................... 176

Map report tags to report limit tags ..................................... 176

Configure parameter and report limit tags ................................ 177

Parameters, reports, and phase classes edits and limit tags

............................................................................................ 178

Sharing phases and operation sequences between units ........ 178

Share a phase or operation sequence ................................ 179

Chapter 17

Create an operation sequence class ......................................... 181

Edit an operation sequence class ........................................ 182

Configure phases

Operation sequence class

configuration

Table of Contents

10 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Edit Operation Sequence Class dialog box - General tab ... 182

Configure operation sequence class general attributes . 183

Edit Operation Sequence Class dialog box - Parameters tab

............................................................................................ 183

Configure parameters for an operation sequence class 184

Edit Operation Sequence Class dialog box - Reports tab ... 185

Configure reports for an operation sequence class ....... 186

Chapter 18

Create an operation sequence .................................................. 189

Edit Operation Sequence dialog box - General tab .............. 190

Configure the general data for an operation sequence ... 190

Edit Operation Sequence dialog box - Arbitration tab ......... 191

Configure the arbitration data for an operation sequence

....................................................................................... 191

Edit Operation Sequence dialog box - Tags tab .................. 192

Configure parameters for an operation sequence class 192

Configure reports for an operation sequence class ....... 193

Sharing phases and operation sequences between units ........ 194

Share a phase or operation sequence ................................ 195

Appendix A

Area model object warm restart support ................................... 197

Resource classes warm restart support .................................... 197

Resources warm restart support ............................................... 198

Unit attributes warm restart support ......................................... 198

Unit attribute tags warm restart support ................................... 198

Equipment phase tags warm restart support ............................ 199

Enumeration sets warm restart support .................................... 199

Data servers warm restart support ........................................... 199

Process cell classes warm restart support ............................... 200

Process cells warm restart support .......................................... 200

Unit classes warm restart support ............................................ 201

Units warm restart support ....................................................... 201

Parameters warm restart support ............................................. 202

Added parameters warm restart support ............................. 202

Report warm restart support ..................................................... 202

Added reports warm restart support .................................... 203

Configured messages warm restart support ............................. 203

Recipe phases warm restart support ........................................ 203

Equipment phases warm restart support .................................. 204

Appendix B

Unable to access instruction file ................................................ 207

Illegal characters encountered in writing instruction file ............ 207

Unable to access Material Server for material support ............. 208

COM-related exception errors .................................................. 208

XML parser error messages ................................................ 209

Material-specific errors ........................................................ 209

Operation sequence

configuration

Supported area model changes

for Warm and Warm-All restart

Troubleshoot issues

Table of Contents

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 11

Invalid signoff ........................................................................... 210

Resolve invalid signoff for deleted group or user ................ 211

Resolve invalid signoff for omitted information .................... 212

No Signature templates configured in Area Model ................... 213

Area model secured to different network directory ................... 213

Area model is secured to different network directory ................ 214

Index

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 13

Preface

This manual provides usage instructions for the FactoryTalk Batch

Equipment Editor. It is one of a set of related manuals that describe

installing, programming, and operating the FactoryTalk Batch system.

To review FactoryTalk Batch release notes and latest information

regarding product compatibility refer to the

Product Compatibility and

Download Center (PCDC).

Rockwell Automation publishes legal notices, such as privacy policies,

license agreements, trademark disclosures, and other terms and

conditions on the Legal Notices

page of the Rockwell Automation

website.

Software and Cloud Services Agreement

Review and accept the Rockwell Automation Software and Cloud

Services Agreement here

.

Open Source Software Licenses

The software included in this product contains copyrighted software that

is licensed under one or more open-source licenses.

You can view a full list of all open-source software used in this product

and their corresponding licenses by opening the oss_license.txt file

located your product's OPENSOURCE folder on your hard drive. This file

is divided into these sections:

• Components

Includes the name of the open-source component, its version

number, and the type of license.

• Copyright Text

Includes the name of the open-source component, its version

number, and the copyright declaration.

• Licenses

Includes the name of the license, the list of open-source

components citing the license, and the terms of the license.

The default location of this file is:

C:\Program Files (x86)\Common Files\Rockwell\Help\<product

name>\Release Notes\OPENSOURCE\oss_licenses.txt

You may obtain Corresponding Source code for open-source packages

included in this product from their respective project web site(s).

Alternatively, you may obtain complete Corresponding Source code by

contacting Rockwell Automation via the Contact form on the Rockwell

About the Equipment Editor

manual

Legal Notices

Preface

14 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Automation website:

http://www.rockwellautomation.com/global/about-us/contact/contact.pag

e. Please include "Open Source" as part of the request text.

This table is a comprehensive documentation list for the FactoryTalk®

Batch products from Rockwell Automation.

Installation, Quick Start, and Getting Results Guides

Resource

Description

FactoryTalk Batch Components Installation and

Upgrade Guide

(BATCH-IN002)

Provides information and procedures for FactoryTalk Batch system installation.

Includes information for FactoryTalk Batch Material Manager, FactoryTalk Event

Archiver, and associated FactoryTalk Batch Client and Server components.

FactoryTalk Batch View Quick Start Guide

(FTBVS-QS001)

Provides information about using FactoryTalk Batch View to create, view, and

command control recipes, acknowledge prompts and signatures, view equipment

phases and diagnostic information, and view profile information.

FactoryTalk Batch View HMI Controls Quick Start

Guide

(BATCH-QS001D)

Provides a general overview of FactoryTalk Batch View HMI Controls.

FactoryTalk Batch eProcedure® Getting Results

Guide

(BWEPRO-GR011)

Explains the basics of FactoryTalk Batch eProcedure.

FactoryTalk Batch Getting Results Guide

(BATCH-GR011)

Introduces the basics of automated batch manufacturing and the FactoryTalk Batch

product components.

FactoryTalk Batch Material Manager Getting Results

Guide

(BWMTR-GR011)

Introduces the basics of FactoryTalk Batch Material Manager.

User Guides

Resource

Description

FactoryTalk Batch Material Editor User Guide

(BWMTR-UM001)

Provides access to information and procedural instructions required to configure

materials and the containers to hold them. The material data is stored in the material

database, which is used to create material-based recipes. This information is

intended as a reference for formulators.

FactoryTalk Batch Equipment Editor User Guide

(BATCH-UM004)

Provides information on creating and maintaining an equipment database (area

model). The area model is available to all other FactoryTalk Batch programs, including

the Recipe Editor, Batch View, and Phase Simulator.

FactoryTalk Batch PhaseManager™ User Guide

(BATCHX-UM011)

Describes the integration of the FactoryTalk Batch software with the Studio 5000

Logix Designer® application and the Logix 5000™ family of controllers.

The integration simplifies the configuration and maintenance of the FactoryTalk

Batch automation system, provides better communication between the FactoryTalk

Batch Server and the Logix 5000 controller, and significantly reduces the

programming effort required to develop the phase logic code that resides in your

Logix 5000 controller.

Additional resources

Preface

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 15

Resource

Description

FactoryTalk Batch Recipe Editor User Guide

(BATCH-UM006)

Provides instructions on using FactoryTalk Batch Recipe Editor to create and

configure master recipes for use in batch automation. The interface is based on IEC

61131-3 sequential function charts to organize recipes graphically into procedures, unit

procedures, operations, and phases. Build recipes using either the SFC format or a

table-based format.

FactoryTalk Batch View HMI Controls User Manual

(FTBVS-UM003)

Provides details about using FactoryTalk Batch View HMI Controls to monitor and

interact with the production process within a FactoryTalk View SE Display Client.

FactoryTalk Batch View User Manual

(FTBVS-UM002)

Provides information and procedural instructions for using FactoryTalk Batch View in

a modern and intuitive portal into a comprehensive batching solution for effective

operations, leveraging its own web server using HTML5 technology to provide

connectivity into a FactoryTalk Batch Server.

FactoryTalk Event Archiver User Guide

(BATCH-UM012)

Provides information and instructions specific to the FactoryTalk Event Archiver.

Intended for use by system administrators and production supervisors.

Administrator Guides

Resource

Description

FactoryTalk Batch Administrator Guide

(BATCH-UM003)

Provides instructions for configuring security and services, and implementation and

use of components not typically accessed or used by batch operators, such as the

FactoryTalk Batch Server.

FactoryTalk Batch eProcedure Administrator Guide

(BWEPRO-UM011)

Provides procedures specific to FactoryTalk Batch eProcedure, such as implementing

security.

Included are instructions for tasks specific to FactoryTalk Batch, such as configuring

security and services to support FactoryTalk Batch eProcedure. Provides instructions

on the implementation and use of components not typically accessed or used by

batch operators, such as the FactoryTalk Batch Server.

FactoryTalk Batch Material Manager Administrator

Guide

(BWEPRO-UM011)

Provides information and instructions specific to FactoryTalk Batch Material Manager.

Intended for use by system administrators and database administrators.

Reference Guides

Resource

Description

FactoryTalk Batch Material Server API Reference

Manual

(BWMTR-RM001)

Provides access to information regarding the interface between the FactoryTalk Batch

Material Server and the FactoryTalk Batch Material Editor and FactoryTalk Batch. It is

intended to be used as a reference information by custom interface developers.

FactoryTalk Batch PCD Programming Reference

Manual

(BATCH-RM004)

Provides information and instructions about the FactoryTalk Batch PCD interface

design. It is intended to be used as a reference guide for PCD programmers.

FactoryTalk Batch Server API Reference Manual

(BATCH-RM003)

Provides information regarding the interface between the FactoryTalk Batch Server

and FactoryTalk Batch View — the Server Application Programming Interface (API). It is

intended to be used as a reference guide by custom interface developers.

FactoryTalk Batch System Files Reference Manual

(BATCH-RM005)

Provides the technical information for configuration and maintenance of a

FactoryTalk Batch system. It can be used as a reference information for

implementation engineers and system administrators.

Preface

16 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Resource

Description

FactoryTalk Batch eProcedure Instruction File

Design Reference Manual

(BWEPRO-RM001)

Provides information about building instruction files for manual phases in the

equipment database This information is intended to be used as a reference by

instruction file authors.

View or download publications at

http://www.rockwellautomation.com/literature

. To order paper copies of

technical documentation, contact your local Allen-Bradley® distributor or

sales representative.

Rockwell Automation recognizes that some of the terms that are currently

used in our industry and in this publication are not in alignment with the

movement toward inclusive language in technology. We are proactively

collaborating with industry peers to find alternatives to such terms and

making changes to our products and content. Please excuse the use of

such terms in our content while we implement these changes.

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 17

Chapter 1

FactoryTalk Batch Equipment Editor

Use FactoryTalk Batch Equipment Editor to create and maintain an

equipment database. The area model is the physical component of a

batch facility, a database that consists of all equipment in the facility and

all of the tasks that it is capable of performing. The area model is stored in

a file with a .cfg file extension and is available to all other FactoryTalk

Batch programs, including FactoryTalk Batch Recipe Editor, FactoryTalk

Batch View, and Phase Simulator.

For example, during recipe configuration, the area model provides a list

of available units and phases. Later during recipe verification, it verifies

that the designated equipment is capable of executing the procedures.

During recipe execution, resource arbitration functions use the area

model to allocate equipment based on recipe and operator requests.

Arbitration is a form of coordination control that determines how a

resource allocates when there are more requests for the resource than

can be accommodated at one time.

IMPORTANT

Verify any recipes that run against a new or modified area model and restart the

FactoryTalk Batch Server service.

As outlined in the ISA S88.01 Batch Control Standard, the facility area

model organizes into model components:

• Process Cell

• Unit

• Phase

• Control Module

In addition to the creation of an area model, FactoryTalk Batch

Equipment Editor:

• Defines signature templates for electronic signatures and reci

pe

appr

oval signoffs.

• Configures steps and approval signoffs for recipe approval.

• Enables recipe version control.

• Secures an area model using security authority.

• Specifies server communication functions.

• Specifies FactoryTalk Event Archiver filters and reporting options.

If using FactoryTalk Batch with FactoryTalk Batch Material Manager, set

security for FactoryTalk Batch to access the material database.

See also

FactoryTalk Batch Equipment Editor security on page 18

Chapter 1 FactoryTalk Batch Equipment Editor

18 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Security for FactoryTalk Batch Equipment Editor uses the FactoryTalk

Security product policy settings defined in the FactoryTalk Directory.

Only FactoryTalk Security users have access to FactoryTalk Batch

Equipment Editor.

FactoryTalk Batch Equipment Editor Single Sign-On product policy

setting created in the FactoryTalk Local Directory in conjunction with the

FactoryTalk Use single sign-on system policy setting enables and

disables the FactoryTalk single sign-on. Single sign-on allows users to

log on just once, per directory, on a given computer. Once a user logs on

to the FactoryTalk Directory, all participating FactoryTalk-enabled

products that run in that directory, on that computer, automatically use

the logged on user’s security credentials.

When opening FactoryTalk Batch Equipment Editor, the user logged on

to the FactoryTalk Directory automatically logs on to FactoryTalk Batch

Equipment Editor or the Log on to FactoryTalk dialog box opens

requiring a user name and password.

If enabled, the FactoryTalk Use single sign-on system policy setting

and FactoryTalk Batch Equipment Editor Single Sign-On product policy

setting is True, these scenarios are possible when opening FactoryTalk

Batch Equipment Editor:

• If a FactoryTalk Security user with FactoryTalk Batch Equipment

Editor permissions opens FactoryTalk Batch Equipment Editor

while currently logged on to the FactoryTalk Directory, the security

permissions are the same.

• If a Windows-linked user with FactoryTalk Batch Equipment Editor

permissions opens FactoryTalk Batch Equipment Editor, the user

logs on to the FactoryTalk Directory.

• If a user is not found, the Log on to FactoryTalk dialog box

opens.

Tip: FactoryTalk Windows-linked user: A user account created in Windows and then added to

the FactoryTalk Directory.

If disabled the FactoryTalk Use single sign-on system policy setting or

FactoryTalk Batch Equipment Editor Single Sign-On product policy

setting is False, then the Log on to FactoryTalk dialog box displays and

a FactoryTalk Security user with permissions to open FactoryTalk Batch

Equipment Editor must be entered.

See also

Open FactoryTalk Batch Equipment Editor on page 18

Use these instructions to open FactoryTalk Batch Equipment Editor.

To open FactoryTalk Batch Equipment Editor:

1. Select Start > Rockwell Software > Equipment Editor.

FactoryTalk Batch

Equipment Editor security

Open FactoryTalk Batch

Equipment Editor

Chapter 1 FactoryTalk Batch Equipment Editor

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 19

2. (optional) If the Log On to FactoryTalk dialog box displays, type

the user name and password and then select OK.

3. (optional) If a FactoryTalk user name and password is not found in

the FactoryTalk Directory or if the user is not configured to run

FactoryTalk Batch Equipment Editor, the Logon Message dialog

box opens.

See also

FactoryTalk Batch Equipment Editor security on page 18

Use FactoryTalk Batch Equipment Editor to configure the facility area

model. The components defined in the FactoryTalk Batch Equipment

Editor interface with the facility process-connected devices.

The following illustration shows the FactoryTalk Batch Equipment Editor

interface:

FactoryTalk Batch

Equipment Editor interface

Chapter 1 FactoryTalk Batch Equipment Editor

20 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

The sections of the FactoryTalk Batch Equipment Editor interface

include:

Item

Name

Description

Menu bar

The menu bar shows the available menus.

Toolbar

The toolbar shows all the available operations.

Location bar

The location bar indicates the unit and process cell currently

working. Select

View > Location Bar to show and hide.

Class View area

Shows the existing cell classes, unit classes, or phases in the

active area model. The column heading reflects the active

level. Double-click (or right-click) an icon to open the

Edit

dialog box for that item.

Design View area

Use this area to construct the area model and display the

layout of the active level. In Select mode, double-click an

item to display the layout of the next lower level. Right-click

the item to open the Edit dialog box.

Status bar

The right side of the status bar displays the selected unit,

process cell, and current user name.

See also

Menu bar on page 20

Toolbar on page 20

Area models on page 23

The Menu bar commands include:

Name

Purpose

File

Lists options for opening, creating, saving, securing, importing, exporting, and

verifying/deploying area models.

Edit Edit the various area model components, perform a tag import, and configure signoffs for

recipe approval.

Class

Create a new class of items for the current level.

View Specify the FactoryTalk Batch Equipment Editor components to display, and indicate the zoom

percentage.

Options

Specify directories for area model icons and configure the FactoryTalk Batch Server options.

Server options include project settings (directories, recipe storage file type, recipe versioning

enable and disable), archiver event filters, batch reporting, and other settings.

Help

Provides on-line help and information regarding the software and the system.

See also

FactoryTalk Batch Equipment Editor interface on page 19

The FactoryTalk Batch Equipment Editor toolbar contains a group of

buttons used to perform commands in FactoryTalk Batch Equipment

Editor. The buttons, from left to right, are:

Graphic

Name

Description

Keyboard

Shortcut

New

Creates an area model.

Ctrl + N

Open

Opens an existing area model.

Ctrl + O

Menu bar

Toolbar

Chapter 1 FactoryTalk Batch Equipment Editor

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 21

Graphic

Name

Description

Keyboard

Shortcut

Save

Saves the active area model.

Ctrl + S

Cut

Deletes the highlighted item and saves it to the

clipboard.

Delete

Copy

Copies the highlighted item and saves it to the

clipboard.

Ctrl + C

Paste Pastes the cut or copied item from the clipboard. Ctrl + V

Share

Shares the selected unit or phase class.

Ctrl + H

Go Down

Moves down through the levels and displays the

next lower level.

None

Go Up Moves up through the levels and displays the next

higher level.

None

Zoom

Specifies the magnification of the current

sequential function chart (SFC) display.

None

Add New Object

Opens the appropriate Create dialog box for the

active level.

None

Edit Area Edit the area information. Ctrl + A

Edit Enumerations

Opens the Create Enumeration Sets and

Enumerations dialog box.

Ctrl + M

Edit Servers

Opens the Create Servers dialog box.

Ctrl + D

Synchronize Synchronizes the equipment area model with the

Logix Designer project file.

Ctrl + L

Edit Shared

Resources

Opens the Edit Resources dialog box.

Ctrl + R

Edit Properties

Opens the appropriate Edit dialog box for the

selected item.

Ctrl + E

Edit Tags Opens the

Edit Tags

dialog box. Ctrl + T

Edit Unit Attributes

Opens the Edit Unit Attributes dialog box.

Ctrl + U

Edit Global Binding

Requirements

Opens the

Edit Global Unit Binding Requirements

dialog box.

Ctrl + B

Edit Signature

Templates

Opens the Edit Signature Templates dialog box.

None

Edit Command

Verification Policies

Opens the Edit Command Verification Policies

dialog box.

Ctrl + P

Select Instance

Changes the cursor to the selection tool.

None

Link Units

Changes the cursor to the linking tool. Links

define the upstream and downstream

relationships between units within a process cell.

The FactoryTalk Batch Server uses the links to

determine which units are available for selection

when defining equipment requirements for

procedures.

None

Unlink Units

Changes the cursor to the unlinking tool, to unlink

the units within a process cell.

None

Invoke Recipe Editor

Opens FactoryTalk Batch Recipe Editor.

None

Verify/Deploy Area

Model

Opens the Verify/Deploy dialog box.

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 23

Chapter 2

Area models

An area model is a definition of the manufacturing facilities capabilities

with which the FactoryTalk Batch server interacts. The information for a

facility is stored in a configuration file you build using the FactoryTalk

Batch Equipment Editor and saved as a file with a cfg extension (such as,

SouthPlant.cfg).

The area model contains information about the process equipment used

to create batches. It includes all the equipment configured for one area of

a specific physical plant. An area model corresponds to a single

FactoryTalk Batch Server. The area model configuration file (.cfg) is

used by FactoryTalk Batch Recipe Editor, FactoryTalk Batch Server, and

Phase Simulator.

Create the area model in this order:

• Enumerations

• Data servers

• Resources

• Process cells

• U

nits

• Phase classes

• Phases

In some cases, you need to re-configure upper-level equipment after

defining the lower-level equipment.

Runtime area models

Once the area model is configured it is ready to be brought online and

used during runtime to produce batches. If changes to the area model are

required while it is running you can modify the offline area model and

then deploy it to the runtime area model to respond to the updated

requirements.

Area model configurations are composed of a set of elements that define

the functions of the area. A subset of these elements cannot be changed

when the model is running. After modifying an area model you must verify

it against the runtime area model to confirm that the elements modified

are permitted to be updated. After the area model changes are verified

they can be deployed to the runtime area model.

Licensing support

Making changes to an area model might change the number of unit

licenses required for the FactoryTalk Batch software components.

Chapter 2 Area models

24 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Additional software licenses might need to be acquired or licenses

currently allocated might be able to be released.

When changes to an area model are verified the number of required unit

licenses are calculated. If more licenses are required, a request is made

to the licenses server to grant the number of licenses required. If an error

is encountered during the license check, the updates to the area model

can not be deployed. Any licensing errors are recorded in the

Compare/Update log

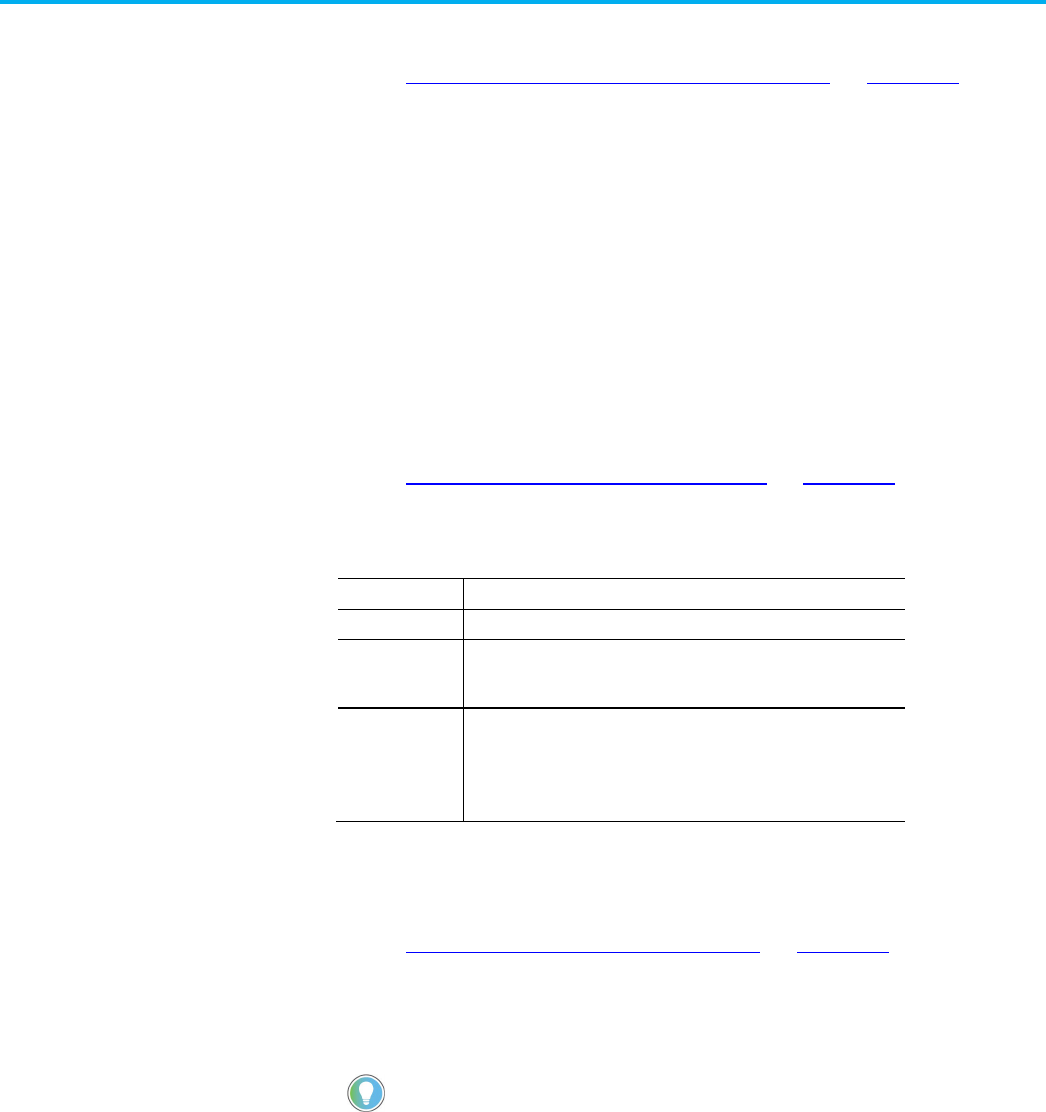

This table describes errors that can be encountered during the license

check:

Error Message

Description

Unable to acquire all

required licenses. %s. Area

Model changes not

permitted.

There are not enough licenses available to satisfy the

license request.

To resolve this issue, request additional licenses or release

any licenses that are currently assigned to inactive units.

Timeout awaiting response

for required licenses from

license server:%s. Area

Model changes not

permitted.

Unable to acquire the licenses from the license server

within the time limit defined on the Batch server. The

default timeout value is 120 seconds.

To resolve this issue, verify connectivity with the Batch

server and the license server. If both servers are

accessible, update the Batch server timeout value to

provide additional time to receive the licenses.

* The placeholder %s represents the a description of the required

licenses.

The batch server will not attempt to acquire or release unit licenses when

performing an area model update in he following conditions:

• When running in demo mode

• When licensed under a distributor license

• When running under a grace period activation

See also

Enumerations overview on page 37

Data servers overview on page 83

Resources overview on page 95

Phase class overview on page 137

Create an area model on page 24

Certain FactoryTalk Batch modules use the area model name to identify

the FactoryTalk Batch system data to associate with the area model.

IMPORTANT

The area name must be unique for each FactoryTalk Batch Server running on a

network.

To create an area model:

1. Select Start > Rockwell Software > Equipment Editor.

Create an area model

Chapter 2 Area models

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 25

2. Select File > New. A blank area model opens.

3. Select Edit Area ( ). The Edit Area dialog box opens.

4. In Name, type a unique name for the area.

5. In Version, type a version number.

6. Select OK to return to the Design View area. The area name

displays in the title bar of the Design View area.

7. Select File > Save.

8. Type an appropriate file name, and then select Save to save the

area model.

The area model saves to the configuration file and can open at any

time for modification.

IMPORTANT

Restart the FactoryTalk Batch Server to initiate the changes and re-verify any

recipes that run against any modified area model.

Tip: If running FactoryTalk Batch Material Manager, and the FactoryTalk Batch Server loses

communications with the Material Server while creating or editing the area model, some of the

enumeration sets contain only the default values — NULL_MATERIAL, NULL_CLASS, and

NULL_CONTAINER.

See also

Open an area model on page 25

Use these instructions to open an area model.

To open an area model:

1. Select Start > Rockwell Software > Equipment Editor.

2. Select File > Open.

3. Locate and select the area model file (.cfg), and then select Open.

Possible error scenario

If security authority is applied to the area model, and there is a mismatch

between the security authority identifier (SAI) in the area model and the

SAI in the FactoryTalk Network Directory, an error message opens:

Before closing the error message take note of the FactoryTalk Network

Directory and host computer information

To recover from this scenario you can either

Open an area model

Chapter 2 Area models

26 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

• Restore the FactoryTalk Network Directory SAI to which the area

model is secured. The name of the computer that hosts that SAI is

provided in the dialog box. Use the FactoryTalk Administration

Console to restore a saved backup of the SAI. Then use File >

Open to open the secured area model.

• Open an unsecured copy of the area model. You must have saved

a copy of the area model prior to securing it to have this recovery

option available.

See also

Area models migration on page 26

Area models and FactoryTalk Batch Material Manager on page 26

When opening area models created using FactoryTalk Batch version

11.00 or later, the option to have the area model automatically migrated

to the latest FactoryTalk Batch version is available. The existing data

migrates to the new schema. If the area model is not migrated, the

current FactoryTalk Batch Equipment Editor version is unable to open.

Tip: If upgrading from a FactoryTalk Batch version older than the previous major release (such as

from version 10.xx or earlier to version 12.xx), contact the Rockwell Customer Support Representative

to have the area model upgraded to the new equipment database schema.

See also

Open an area model on page 25

When opening area models containing enumeration sets of the same

name as the system enumeration sets (YES_NO, and if FactoryTalk

Batch Material Manager is supported, MATERIALS,

MATERIAL_CLASSES, and CONTAINERS), rename these

non-FactoryTalk Batch Material Manager enumeration sets. Renaming

the enumeration sets updates all parameters, report parameters, and

unit attribute tags to the renamed enumeration set and creates the new

system enumeration set. If not renamed, the area model cannot open in

the current FactoryTalk Batch Equipment Editor version.

Tip: When using FactoryTalk Batch Material Manager in conjunction with FactoryTalk Batch, there is a

dependency between the area model and the material database. When an area model opens, the

MATERIALS and CONTAINERS enumeration sets recreate, based on the materials and containers that

exist in the material database. If the Material Server is unavailable, the enumeration sets contain only

the default values — NULL_MATERIAL and NULL_CONTAINER.

See also

Open an area model on page 25

Material database changes on page 26

Material database is unavailable on page 27

FactoryTalk Batch Material Manager only.

If a member of the MATERIAL enumeration set previously assigned to a

Area models migration

Area models and

FactoryTalk Batch Material

Manager

Material database changes

Chapter 2 Area models

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 27

phase class is no longer in the material database, a warning message

displays an error.

• Select Continue to substitute the NULL_MATERIAL enumeration

for the unsupported enumeration.

• Select Cancel to open the area model unchanged. When affected

phase class’s Parameter tab opens, the first enumeration in the

alphabetically sorted list substitutes for the unsupported

enumeration.

IMPORTANT

The controller ID of a material and container is the ordinal value for the

enumeration. If modified the item controller ID in the material database, the

ordinal value of the associated enumeration changes. This change could affect

the phase logic.

See also

Material database is unavailable on page 27

Area models and FactoryTalk Batch Material Manager on page 26

The MATERIALS and CONTAINERS enumeration sets recreate each

time an area model creates, opens, or imports. If the Material Server is

unavailable, the enumeration sets only contain the default values —

NULL_MATERIAL and NULL_CONTAINER.

See also

Area models and FactoryTalk Batch Material Manager on page 26

Material database is

unavailable

Material capability removal

Chapter 2 Area models

28 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

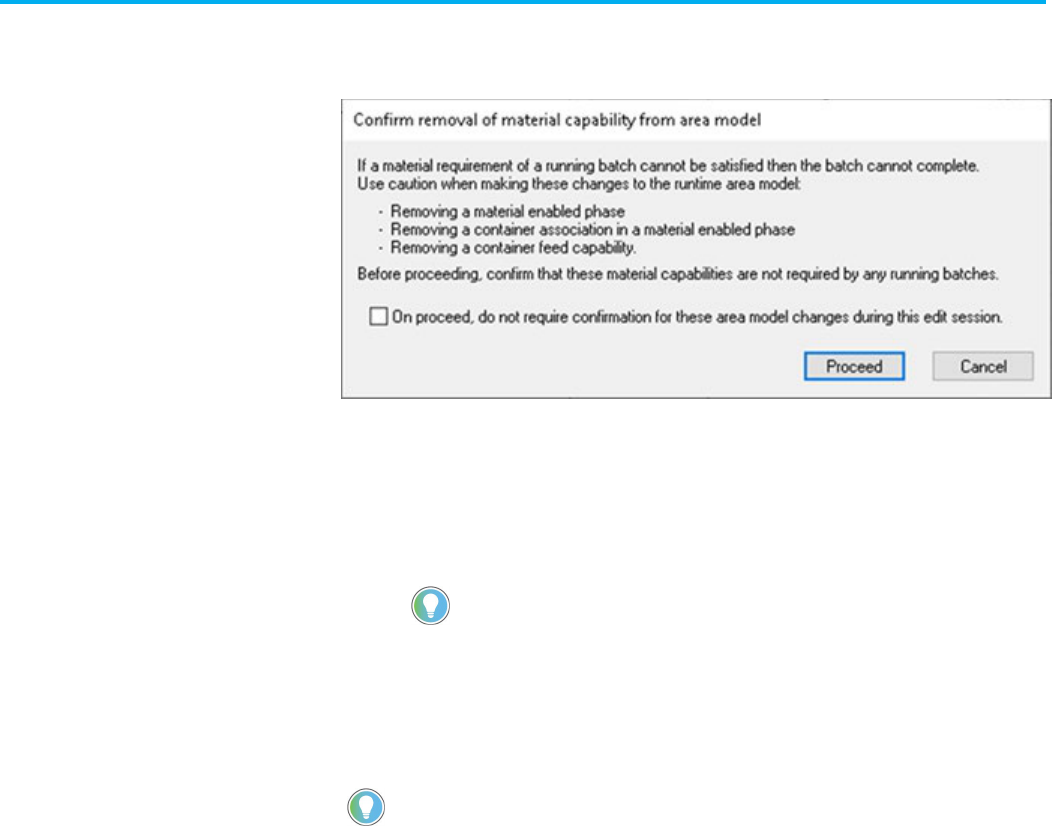

If a change to an area model removes a material capability that could

result in batches that are unable to complete due to the inability to satisfy

a material requirement, this confirmation message is displayed.

This confirmation will occur if any of these changes are made to the area

model:

• Removal or unsharing of a material enabled phase

• Removal of a container association from a material-enabled phase

• Removal of the distribution capability of a container association

• Removal of the addition capability of a container association

Tip: If you are making several edits to the material capabilities of the area model, select the

checkbox to not require confirmation of every subsequent edit.

To prepare an area model for deployment, an operator can verify that

changes made to the area model are permitted.

Then, the operator can deploy changes to the runtime area model.

Tip: An area model can also be verified and deployed from the FactoryTalk Batch Service Manager.

For more information about updating online area models, see the FactoryTalk Batch Administrator

Guide.

To verify an area model using the FactoryTalk Batch Equipment

Editor

1. Select Start > Rockwell Software > Equipment Editor.

2. Select File > Open.

3. Locate and select the area model file (.cfg) to be verified, and then

select Open.

4. Select File > Verify/Deploy....

5. In the Verify/Deploy Area Model dialog box, review the

information and select Verify Area Model to compare the original

area model with the changed area model.

6. If the verification is not successful, a message displays. Select

View Log to view the reason for the differences that are not

permitted.

7. Select Close.

Verify and deploy area

model

Chapter 2 Area models

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 29

To deploy an area model using the FactoryTalk Batch Equipment

Editor

1. Select Start > Rockwell Software > Equipment Editor.

2. Select File > Open.

3. Locate and select the area model file (.cfg) to be deployed, and

then select Open.

4. Select File > Verify/Deploy....

5. In the Verify/Deploy Area Model dialog box, select Deploy Area

Model.

The Status area displays whether or not the deployment is

allowed. If it is not successful, a message displays. Select View

Log to view the details.

Tip: If an operator attempting to deploy an area model does not have FactoryTalk

permissions, the Deploy Area Model button is disabled.

6. Select Close.

IMPORTANT

The FactoryTalk eProcedure Server does not automatically pick up the changes

deployed to the area model. To update the eProcedure Server:

1. Open the

FactoryTalk Batch Service Manager

.

2. In

Service

, select

FactoryTalk eProcedure Server

.

3. In the

Server

area, clear the

Cold Boot

checkbox.

4. In

Service State

, click

Stop

, then click

Start/Continue

.

This performs a warm restart of the FactoryTalk eProcedure server that applies

the changes in the area model to the currently running batches.

The warm restart of the eProcedure Server while there are active instructions

will cause a phase communication error which may causes batches to be held.

See also

Area models on page 23

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 31

Chapter 3

Import and export area models

FactoryTalk Batch gives the ability to import XML area models or export

area models to XML format. XML provides a standard, non-proprietary

format for distributing the area model configuration.

See also

Import an XML area model on page 31

Export an area model to XML on page 34

XML schemas and XML instance documents have become the industry

standard for providing implementation of neutral information. With

FactoryTalk Batch, FactoryTalk Batch Equipment Editor can import and

export an area model in XML format. This function allows for the

exchange of the area model information with other companies in a

standard, non-proprietary XML format. The area model information may

be edited using text editors or XML editors.

Tip: When securing an area model to a Security Authority Identifier, the Export command disables,

and the area model cannot export.

See also

Import an XML area model on page 31

Export an area model to XML on page 34

Convert XML to binary from the command line overview on page

34

When an XML area model imports, FactoryTalk Batch Equipment Editor

constructs the area model in memory. Save the imported area model to

the proprietary binary file or export it to another text file.

FactoryTalk Batch Equipment Editor validates the information provided

by the XML file. Only well-formed, validated XML files import. The XML

files must have the extension .axml to import. FactoryTalk Batch

Equipment Editor attempts to read the files as XML files only if the files

have the correct file extension.

Files with extensions other than .axml read as tab-delimited files.

Although the .txt file extension is expected for the tab-delimited text files,

FactoryTalk Batch Equipment Editor attempts to read all files with

extensions other than .axml as tab-delimited text files.

XML area models

Import an XML area model

Chapter 3 Import and export area models

32 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

Tip: The YES_NO, MATERIALS, MATERIAL _CLASSES, and CONTAINERS enumeration sets recreate each

time a new area model creates, opens, or imports. Existing values are not imported. If the Material

Server is not available, the MATERIALS, MATERIAL_CLASSES, and CONTAINERS enumeration sets create

with the NULL_MATERIAL, NULL_CLASS, and NULL_CONTAINER default values only. (See

Import

enumerations for more information.)

To import an XML area model:

1. Select Start > Rockwell Software > Equipment Editor.

2. Select File > Import.

3. From the Files of type list, select XML Files (*.axml).

4. Locate and select the XML file to import.

5. Select Open to initiate the import process. A message box

displays the name of each component imported and validated.

6. Select OK to complete the import process and return to

FactoryTalk Batch Equipment Editor.

7. Select File > Save As to save the newly imported file.

The Save As dialog box opens with Untitled.cfg highlighted in the

File name box.

8. In File name, type the new file name. Give the file the same name

as the currently selected area model to overwrite the current file.

9. Select Save. The new area model saves and the file name

displays on the FactoryTalk Batch Equipment Editor title bar.

Tip: If the file name is anything other than the area model currently selected in the Server

Options

dialog box, change the

Server Options

settings before the new area model is used.

See also

Import enumerations on page 32

Import system phase classes on page 33

Create and maintain these system enumeration sets in FactoryTalk

Batch Equipment Editor:

• PHASE_FAILURES

• YES_NO

• REPORTING_CONTEXTS

• MATERIALS (with an installed Material Server)

• MATERIAL_CLASSES (with an installed Material Server )

Import enumerations

Chapter 3 Import and export area models

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 33

• CONTAINERS (with an installed Material Server)

With the exception of PHASE_FAILURES and

REPORTING_CONTEXTS, the data type or the members of these

system-maintained enumeration sets cannot change. The XML file must

include these system enumeration sets for validation against the

schema. These system enumeration sets cannot import.

Tip: The PHASE_FAILURES AND REPORTING_CONTEXTS system enumeration sets can import along

with any user-defined enumerations in these enumeration sets.

See also

Import an XML area model on page 31

Import system phase classes on page 33

FactoryTalk Batch Equipment Editor creates and maintains these

system phase class sets:

• $NULL

• $TIMER

On import of system phase classes, the entire phase class validates and

only those that match completely import.

Tip: If any of the system phase classes ($TIMER or $NULL) contain errors, only the first error show.

$NULL phase

The $NULL phase class validates:

• The name of the phase class must be $NULL.

• There must be no configured recipe or report parameters.

• There must be no configured messages.

• There must be no configured control strategies.

• There must be no configured request parameters.

• There must be no configured message partners.

• All other configurable values are not set.

$TIMER phase

The $TIMER phase class validates:

• The name of the phase class must be $TIMER_X (where X is the

type of Timer and the unit of measure; for example,

$TIMER_DN_SECOND or $TIMER_UP_DAY).

• There must be no configured messages.

• There must be no configured control strategies.

• There must be no configured request parameters.

• There must be no configured message partners.

Import system phase

classes

Chapter 3 Import and export area models

34 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

See also

XML area models on page 31

FactoryTalk Batch allows export of an area model to a well-formed XML

format. With the exception of PHASE_FAILURES and

REPORTING_CONTEXTS, the data type or the members of the

system-maintained enumeration sets cannot change. The XML file must

include these system enumeration sets for validation against the

schema. These system enumeration sets can export but cannot import.

All system phases ($NULL or $TIMER) export. All associated recipe and

report parameters and associated data (for $TIMER_X phases) are part

of the export (for example, where X is the type of Timer and the unit of

measure; $TIMER_DN_SECOND or $TIMER_UP_DAY).

Tips:

• The PHASE_FAILURES AND REPORTING_CONTEXTS system enumeration sets export along with any

user-defined enumerations in these enumeration sets.

• When an area model secures to a FactoryTalk Network Directory Security Authority Identifier, the

Export command is disabled.

To export an area model to XML:

1. Select Start > Rockwell Software > Equipment Editor.

2. Select File > Open to open the area model.

3. Select File > Export. The File Export As dialog box opens.

4. Locate and select the file to export the area model or, in File

name, type a new file name.

5. In Save as type, select XML Files (*.axml).

6. Select Save to initiate the export process. If the file already exists,

confirm to replace the file.

7. Select OK to complete the export process and return to

FactoryTalk Batch Equipment Editor.

See also

Import and export area models overview on page 31

Convert XML area models to the proprietary binary format from the

command line using the supplied program AreaModelConvert.exe.

Only well-formed, schema-conformed, and program-validated XML files

convert.

When exporting from a command line, change to the directory containing

AreaModelConvert.exe and the paths cannot contain any spaces. UNC

names are also supported, as demonstrated in this syntax example:

The syntax for the command line is:

C:AreaModelConvert.EXE InputFile OutputFile LogFile

Where:

• InputFile specifies the path for the input XML filename.

• OutputFile specifies the path for output binary filename.

• LogFile specifies the path for log file.

Export an area model to

XML

Convert XML to binary from

command line

Chapter 3 Import and export area models

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 35

Example:

C:AreaModelConvert.EXE

\\Batchctl\SampleDemo1\recipes\ice_cream1.axml

\\Batchctl\SampleDemo1\recipes\ice_cream1.cfg

\\Batchctl\SampleDemo1\logs\convert.log

The command line validates the information in the XML file and

overwrites the existing file specified by OutputFile. Error messages

append to the log file.

IMPORTANT

The command line program will not validate material-specific information, which

includes:

• Running status of the Material Server

• Existence of the referenced materials

• Existence of the referenced material classes

• Existence of the referenced containers

If the command line arguments are valid, the program returns a 0 (zero),

indicating a successful import. If the command line arguments are invalid,

the command line program returns a 1 (one), indicating a failure. View the

return code in the log file to check if the conversion succeeded or failed.

See also

Export an area model to XML on page 34

Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023 37

Chapter 4

Enumerations overview

Enumerations are system objects that are defined as a variable data type

consisting of a numeric value (called an ordinal value) and an associated

text string. The process-connected device (PCD) and the FactoryTalk

Batch Server communicate using the numeric ordinal value. The server

then displays the ordinal value associated text string to the operator. Use

enumerations to display meaningful text to an operator, instead of a

number.

Enumeration sets contain groupings of related enumerations. The

FactoryTalk Batch and the PCD create and maintain these default

system enumeration sets:

• PHASE_FAILURES

• YES_NO

• MATERIALS (for Material Server-installed system)

• MATERIAL_CLASSES (for Material Server-installed system)

• CONTAINERS (for Material Server-installed system)

• REPORTING_CONTEXTS

The data type and the members of the YES_NO, MATERIALS,

MATERIAL_CLASSES, or CONTAINERS system-maintained

enumeration sets cannot change.

Create custom enumerations and enumeration sets within an area

model.

Use negative ordinal as shown in this example.

The agitator in Premixer B (Unit #2) might use:

Enumeration Set Name --> MOTORS

Enumeration Name

Ordinal

String

Enumeration_1 0 OFF

Enumeration_2

1

FORWARD

Enumeration_3

-1*

REVERSE

See also

System enumeration sets on page 37

Create enumeration sets on page 38

There are five default system enumeration sets. The data type or the

members of these system-maintained enumeration sets are not allowed

to change, except for the Phase_Failures and Reporting_Contexts

enumeration sets.

System Enumeration Set

Purpose

System enumeration sets

Chapter 4 Enumerations overview

38 Rockwell Automation Publication BATCH-UM004C-EN--D - November 2023

System Enumeration Set

Purpose

PHASE_FAILURES

By default, there are no members in this enumeration set.

Add enumerations based on the particular implementation

requirements.

IMPORTANT PHASE_FAILURES enumerations cannot have ordinal values greater than 32767 or less than 0 (zero).

REPORTING_CONTEXTS This enumeration set makes it possible to add reporting

context strings to phase class parameters and reports. The

events about the sets may be more easily queried and

sorted. Add, remove, and edit enumeration set members to

this enumeration set. The default enumeration is NULL,

with an ordinal value of 0.

PHASE_FAILURES and REPORTING_CONTEXTS are the only system enumeration sets to which enumerations can

be added. System enumeration sets display in bold text to differentiate them from custom enumeration sets.

YES_NO This is a simple enumeration set that contains two

members: NO with an ordinal value of 0 and YES with an

ordinal value of 1. This enumeration set cannot be

modified.

MATERIALS (for Material Server-installed system)

Represents the set of materials configured in the

FactoryTalk Batch Material Manager material database. The

default enumeration is NULL_MATERIAL, with an ordinal

value of 0. This value allows assignment of an enumeration

to a parameter of type MATERIALS, which delays the actual

material assignment until the recipe is built. All other

enumeration set members are recreated each time an area

model creates, opens, or imports, based on the material

data in the material database. The controller ID range for

Materials is from 1 through 9999999999.

CONTAINERS (for Material Server-installed system)

Represents the set of containers configured in the

FactoryTalk Batch Material Manager material database. The

default enumeration is NULL_CONTAINER, with an ordinal

value of 0. All other enumeration set members are

recreated each time an area model creates, opens, or

imports, based on the container data in the material

database. The controller ID range for Containers is from

1

through 9999999999.

If the FactoryTalk Batch Material Manager material database is unavailable, the MATERIALS and CONTAINERS